Phosphogypsum stabilized collapsible loess roadbed material and preparation method thereof

A technology for collapsible loess and roadbed materials, which is applied in the field of phosphogypsum-stabilized collapsible loess roadbed materials and its preparation, can solve the problems of insufficient utilization rate, occupation of land resources, pollution of the environment, etc., and achieve reasonable formula, simple preparation method, The effect of large social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of phosphogypsum stabilized collapsible loess roadbed material, comprising the following steps:

[0026] Step 1), crushing phosphogypsum, slaked lime, and collapsible loess into granules for subsequent use;

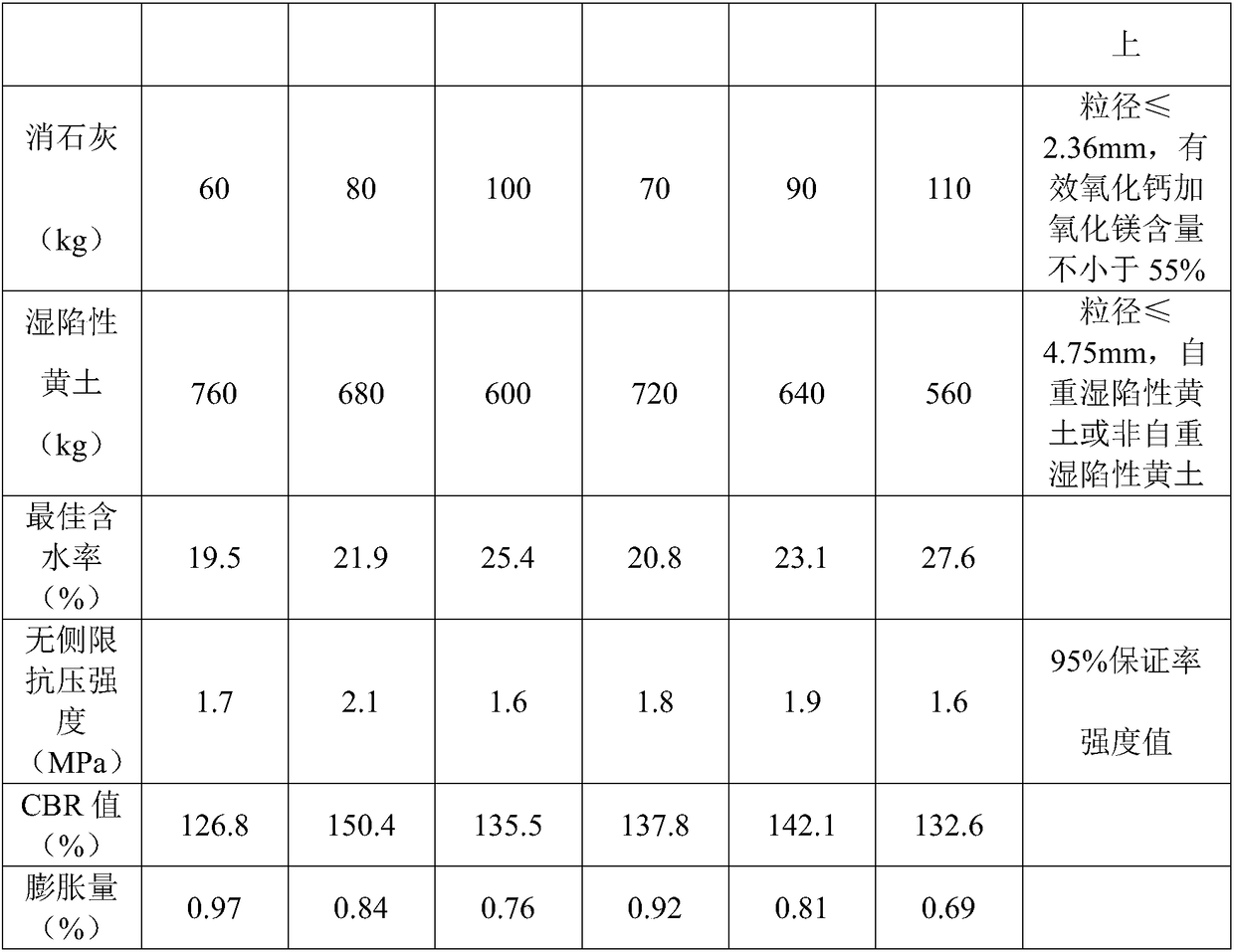

[0027] Step 2), get phosphogypsum, fly ash, slaked lime, collapsible loess according to mass percentage according to 6~11%: 12~22%: 6~11%: 56~76%, with phosphogypsum, fly ash and Slaked lime was stirred evenly under normal temperature conditions to obtain product A;

[0028] Step 3), then the collapsible loess and product A are stirred evenly under normal temperature conditions to obtain product B;

[0029] Step 4), the product B and water are fully stirred according to the mass ratio of 1: (0.195-0.276) under normal temperature conditions, and the product C is obtained, that is, the finished product of phosphogypsum stabilized collapsible loess roadbed material.

[0030] In step 1), the particle size of phosphogypsum and collapsible loess is...

Embodiment 1

[0032] Step 1), breaking phosphogypsum, slaked lime, and collapsible loess into granules, wherein: the particle diameter of phosphogypsum and collapsible loess is 4.75mm, and the particle diameter of slaked lime is 2.36mm;

[0033] Step 2), take 6% of phosphogypsum, 12% of fly ash, 6% of slaked lime, and 76% of collapsible loess according to the mass percentage, and mix phosphogypsum, fly ash and slaked lime evenly under normal temperature conditions to obtain product A;

[0034] Step 3), then the collapsible loess and product A are stirred evenly under normal temperature conditions to obtain product B;

[0035] Step 4), the product B and water are mixed at a ratio of 1:0.195 at room temperature, and the product C is obtained, that is, the finished phosphogypsum stable collapsible loess roadbed material is obtained.

[0036] The phosphogypsum stabilized collapsible loess subgrade material obtained through the above steps was formed into a test piece with the maximum compactnes...

Embodiment 2

[0038] Step 1), breaking phosphogypsum, slaked lime, and collapsible loess into granules, wherein: the particle diameter of phosphogypsum and collapsible loess is 4.75mm, and the particle diameter of slaked lime is 2.36mm;

[0039] Step 2), take 8% of phosphogypsum, 16% of fly ash, 8% of slaked lime and 68% of collapsible loess according to the mass percentage, and mix phosphogypsum, fly ash and slaked lime evenly at normal temperature to obtain product A;

[0040]Step 3), then the collapsible loess and product A are stirred evenly under normal temperature conditions to obtain product B;

[0041] Step 4), mix the product B and water according to the ratio of 0.219 to 1:0.210 at room temperature to obtain the product C, which is the finished product of phosphogypsum stable collapsible loess roadbed material.

[0042] The phosphogypsum stabilized collapsible loess subgrade material obtained through the above steps was formed into a test piece with the maximum compactness, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com