Foamed concrete composite wall plate core and preparation method thereof

A technology of foam concrete and composite wall panels, which is applied in the field of building materials, can solve the problems of low core material strength and low compressive strength, and achieve the effects of saving natural resources, broadening the use channels, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

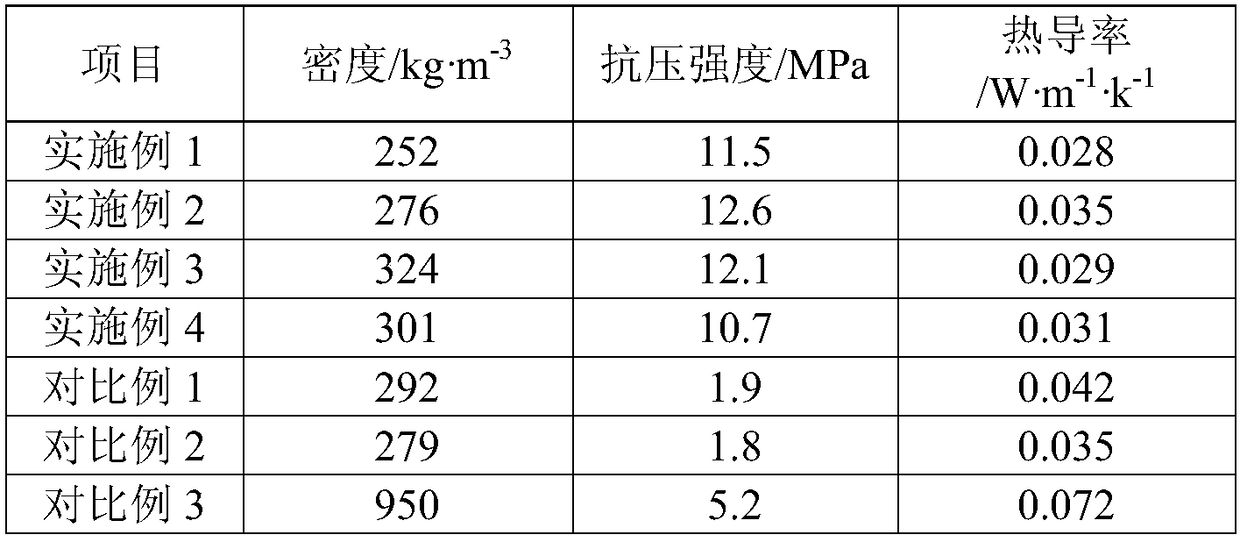

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing the core material of a foam concrete composite wallboard, the preparation method being:

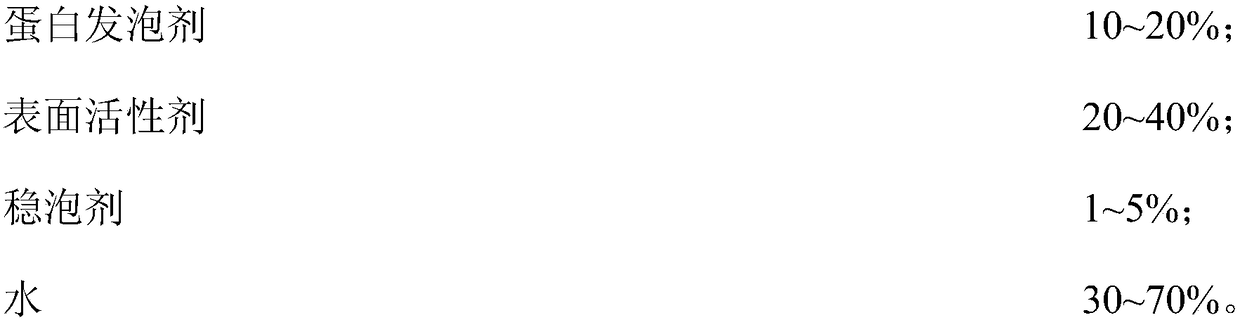

[0041] 95wt% Portland cement, 5wt% construction waste regenerated micropowder, 4wt% 6mm rice straw fiber, 2wt% polycarboxylate water reducer, 1.5wt% early strength agent triisopropanolamine, 2.5% The quick-setting agent is mixed with water 0.6 times the total mass of all the above-mentioned raw materials to obtain cement slurry; 20wt% vegetable protein foaming agent, 40wt% sodium dodecylsulfonate, 5wt% cellulose ether and 35wt% water are mixed to obtain foam; Foam and cement slurry are mixed according to 0.5L of foam per kilogram of cement slurry to obtain foam concrete slurry; the foam concrete slurry is poured into a mold, hydration hardened and demolded to form the foam concrete composite wallboard core material.

Embodiment 2

[0043] This embodiment provides a method for preparing the core material of a foam concrete composite wallboard, the preparation method being:

[0044] 70wt% Portland cement, 10wt% fly ash, 20wt% construction waste regenerated micropowder and main raw material quality 1wt% 10mm cotton stalk fiber, 2wt% polycarboxylate water reducer, 1wt% early strength agent triethanolamine, 6 % Accelerator is mixed with 0.3 times the water of the total mass of all the above-mentioned raw materials to obtain cement slurry; 10wt% animal protein foaming agent, 20wt% sodium dodecylsulfonate, 1wt% calcium stearate and 69wt% water are mixed to obtain Foam; mix foam and cement slurry at 2L of foam per kilogram of cement slurry to obtain foam concrete slurry; pour the foam concrete slurry into a mold, hydration harden and demould to make the foam concrete composite wallboard core material.

Embodiment 3

[0046] This embodiment provides a method for preparing the core material of a foam concrete composite wallboard, the preparation method being:

[0047] 75wt% Portland cement, 10wt% fly ash, 15wt% construction waste regenerated micropowder and main raw material quality 2wt% 5mm carbon fiber, 0.5wt% polycarboxylate water reducer, 0.5wt% early strength agent triisopropanol Amine, 2% quick-setting agent and 0.5 times the water of the total mass of all the above-mentioned raw materials are mixed to obtain cement slurry; Cellulose ether and 50wt% water are mixed to obtain foam; the foam and cement slurry are mixed according to 1.5L of foam per kilogram of cement slurry to obtain foam concrete slurry; the foam concrete slurry is poured into the mold, and the hydration hardening demoulding is made into the Foam concrete composite wall panel core material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com