Flame retardant rail transit vehicle interior floor

A rail transit vehicle and floor technology, which is applied to vehicle parts, fire-resistant and flame-retardant filament manufacturing, railway car bodies, etc., can solve the problems of quality control cost and processing cost increase, lower yield rate of molded parts, high load, etc., to achieve Reduce glue spraying process, good durability and high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

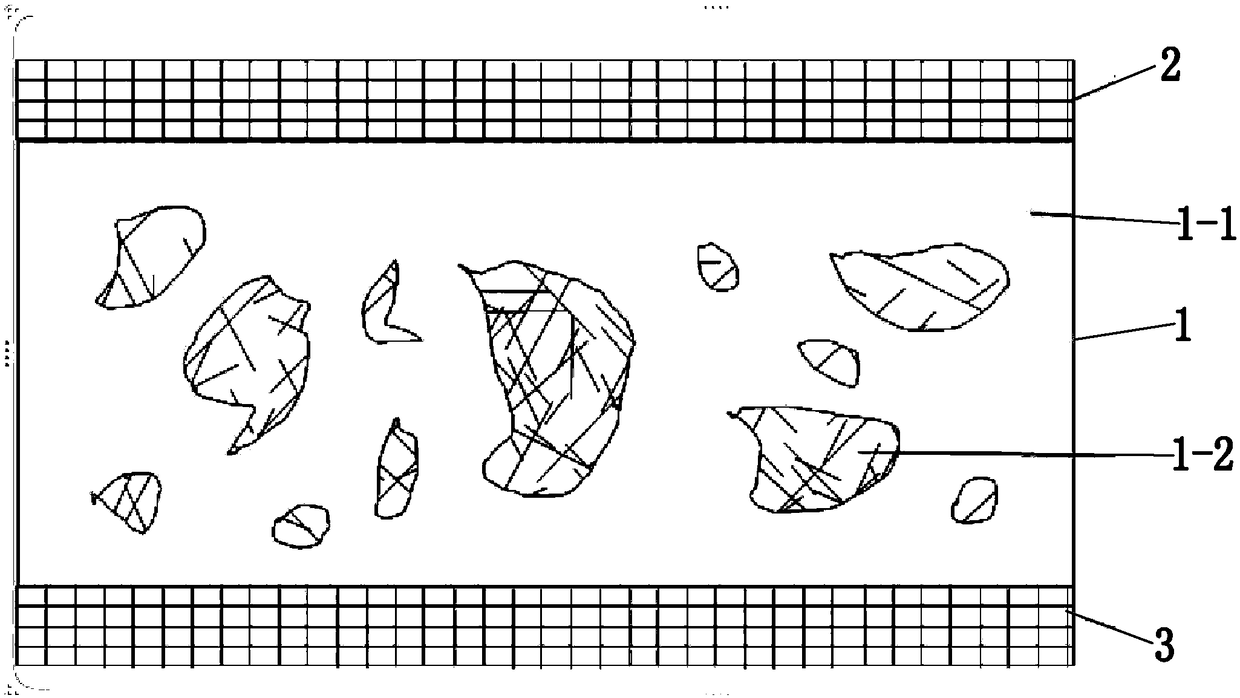

[0020] Such as Figure 1-2 As shown, a flame-retardant rail transit vehicle interior flooring includes an upper surface layer 2, a core material 1 and a lower surface layer 3 arranged in sequence; The core material 1 is composed of thermoplastic polymer fibers 1-1 and glass fibers 1-2; the upper surface layer 2 and the lower surface layer 3 are multi-layer unidirectional continuous glass fiber reinforced thermoplastic resin prepreg sheets and / or Or glass fiber fabric reinforced thermoplastic resin prepreg sheet and / or a fabric woven from glass fiber and thermoplastic resin co-extruded fiber; the rail transit vehicle floor of the present invention, the composite surface layer is reinforced by multi-layer unidirectional continuous glass fiber Thermoplastic resin prepreg and / or glass fiber fabric reinforced thermoplastic resin prepreg and / or fabric woven from glass fiber and thermoplastic resin co-extruded fibers, layer by layer, so that the fibers form an interlaced grid, ensuri...

Embodiment 2

[0026] A flame-retardant rail transit vehicle interior floor, comprising an upper surface layer 2, a core material 1 and a lower surface layer 3 arranged in sequence; the upper surface layer 2 and the lower surface layer 3 are hot-pressed by glass fiber fabric reinforced thermoplastic resin prepreg Composite, the content of glass fiber in the glass fiber fabric reinforced thermoplastic resin prepreg is 60wt%, the thickness is 1mm, and the density is 1500kg / m 3 . Its polypropylene flame-retardant formula is the same as that of Example 1; the core material is a thermoplastic material processed by flame-retardant polypropylene fibers and glass fibers through non-woven equipment and undergoing processes such as unpacking, carding, web laying, acupuncture, and hot pressing. Lightweight composite material plate, the content of glass fiber is 55wt%, the hot pressing molding temperature is 220°C, and the molding pressure is 10MPa. Its areal density is 6.5kg / m 2 . The formula of fla...

Embodiment approach 3

[0029] A flame-retardant rail transit vehicle interior floor, comprising an upper surface layer 2, a core material 1 and a lower surface layer 3 arranged in sequence; the upper surface layer 2 and the lower surface layer 3 are woven by co-extruded fibers of glass fiber and thermoplastic resin The fabric is hot-pressed and compounded. The glass fiber and thermoplastic resin co-extrusion fiber are woven into a fabric with a glass fiber content of 50wt%. The fabric structure is 1 upper and 2 lower twill, the thickness is 1mm, and the density is 1450kg / m 3 . Its polypropylene flame-retardant formula is the same as that of Example 1; the core material is a thermoplastic material processed by flame-retardant polypropylene fibers and glass fibers through non-woven equipment and undergoing processes such as unpacking, carding, web laying, acupuncture, and hot pressing. Lightweight composite material plate, the content of glass fiber is 55wt%, the hot pressing molding temperature is 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com