MEMS device, sound transducer, method for forming the MEMS device, and method for operating such MEMS device

A technology of equipment and conductive layers, applied in the direction of semiconductor electrostatic transducers, electrostatic transducer microphones, electrostatic transducer speakers, etc., can solve the problem of affecting MEMS microphones, and the electrical output signal does not provide sufficient correction of the audible input signal. , sound waves or sound pressure changes, etc., to achieve the effect of high mechanical robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

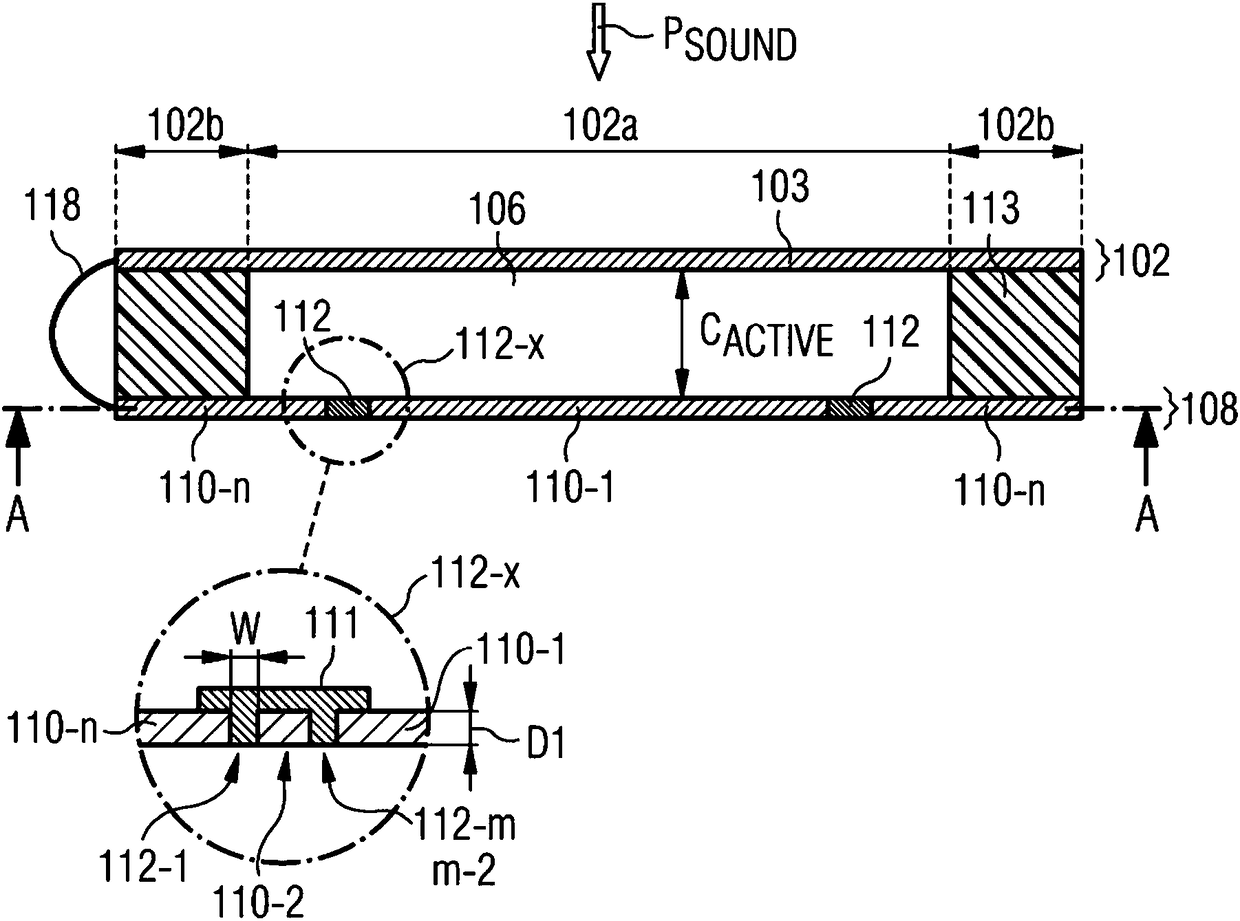

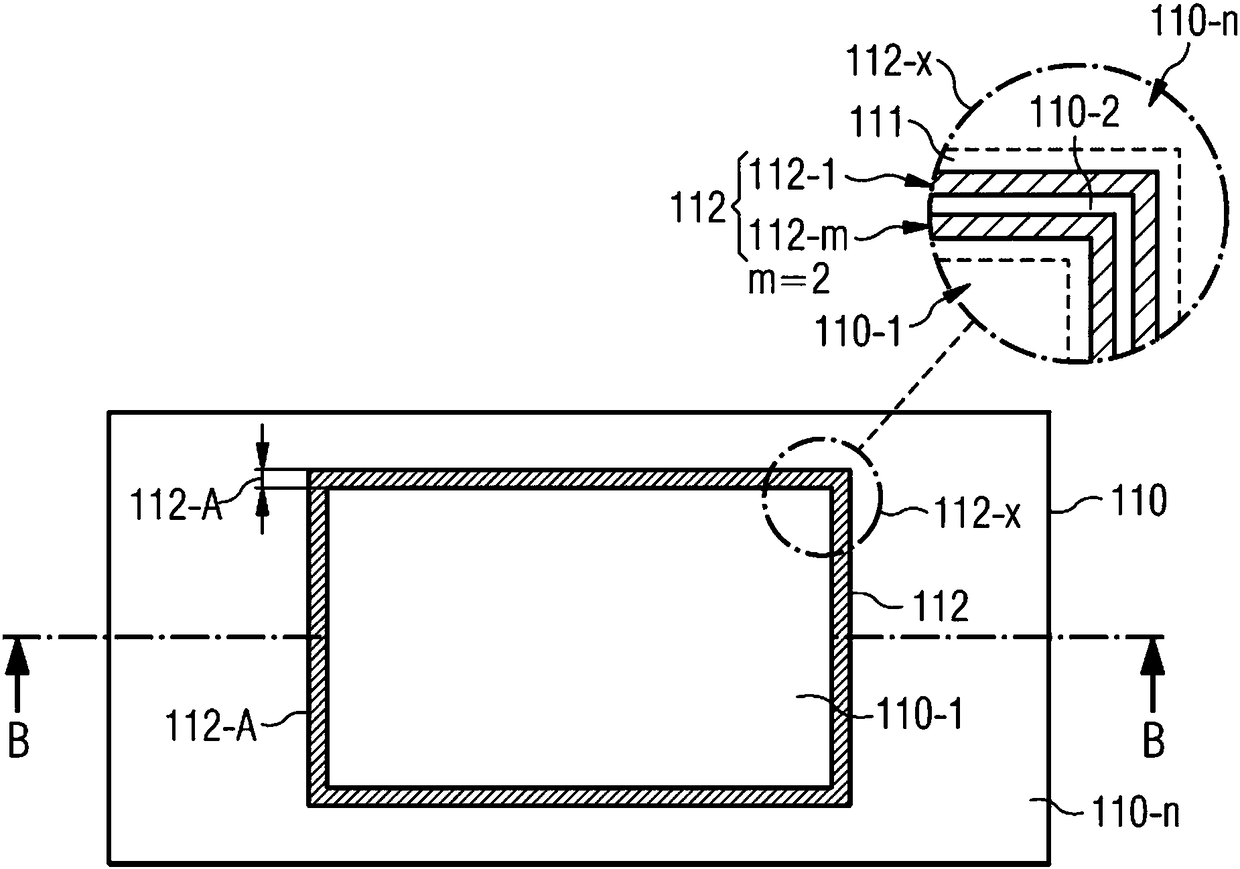

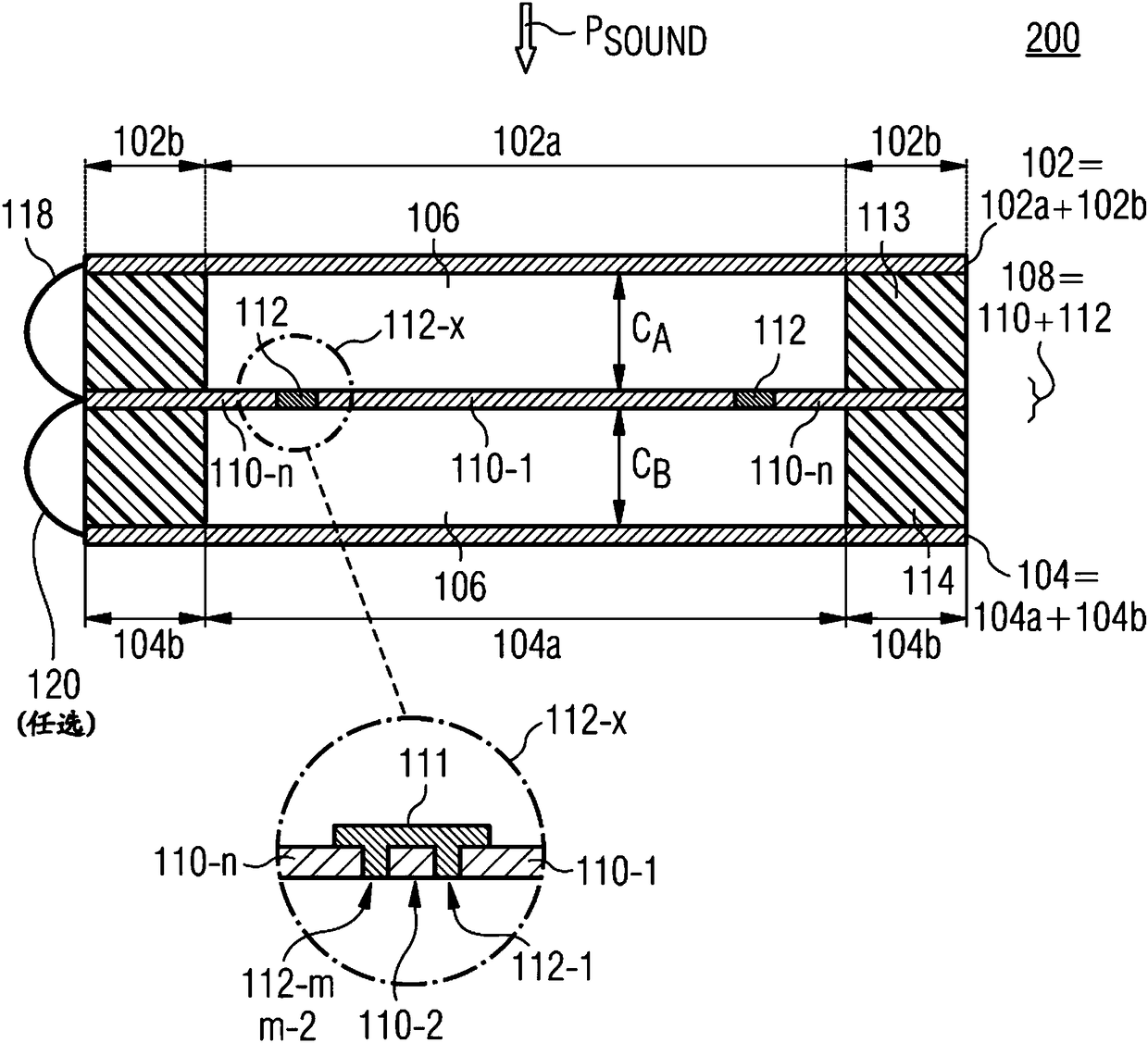

[0030] In the following description, embodiments are discussed in detail, however it should be understood that the embodiments provide many applicable concepts that can be implemented in various specific semiconductor devices that can be capacitively read, such as capacitive MEMS devices. The specific embodiments discussed are merely specific ways to make and use the inventive concepts, and do not limit the scope. In the description of the following embodiments, the same or similar elements having the same function have the same reference symbols or the same names, and descriptions of such elements are not repeated for each embodiment. Furthermore, features of different embodiments described herein may be combined with each other unless explicitly stated otherwise.

[0031]In the following, the inventive concept is generally described with respect to embodiments in the case of capacitive MEMS devices, where the following description is also applicable to any MEMS acoustic tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com