Ionic gel polymer electrolyte with damage repairing capability, preparation method and application of ionic gel polymer electrolyte

An ion gel, a technology for repairing damage, applied to circuits, electrical components, secondary batteries, etc., can solve problems such as battery failure, short-circuit safety, accidents, etc., and achieve high safety, good processing performance, and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of an ionogel electrolyte membrane based on quadruple hydrogen bond UPy crosslinking, and testing of repair performance and battery performance:

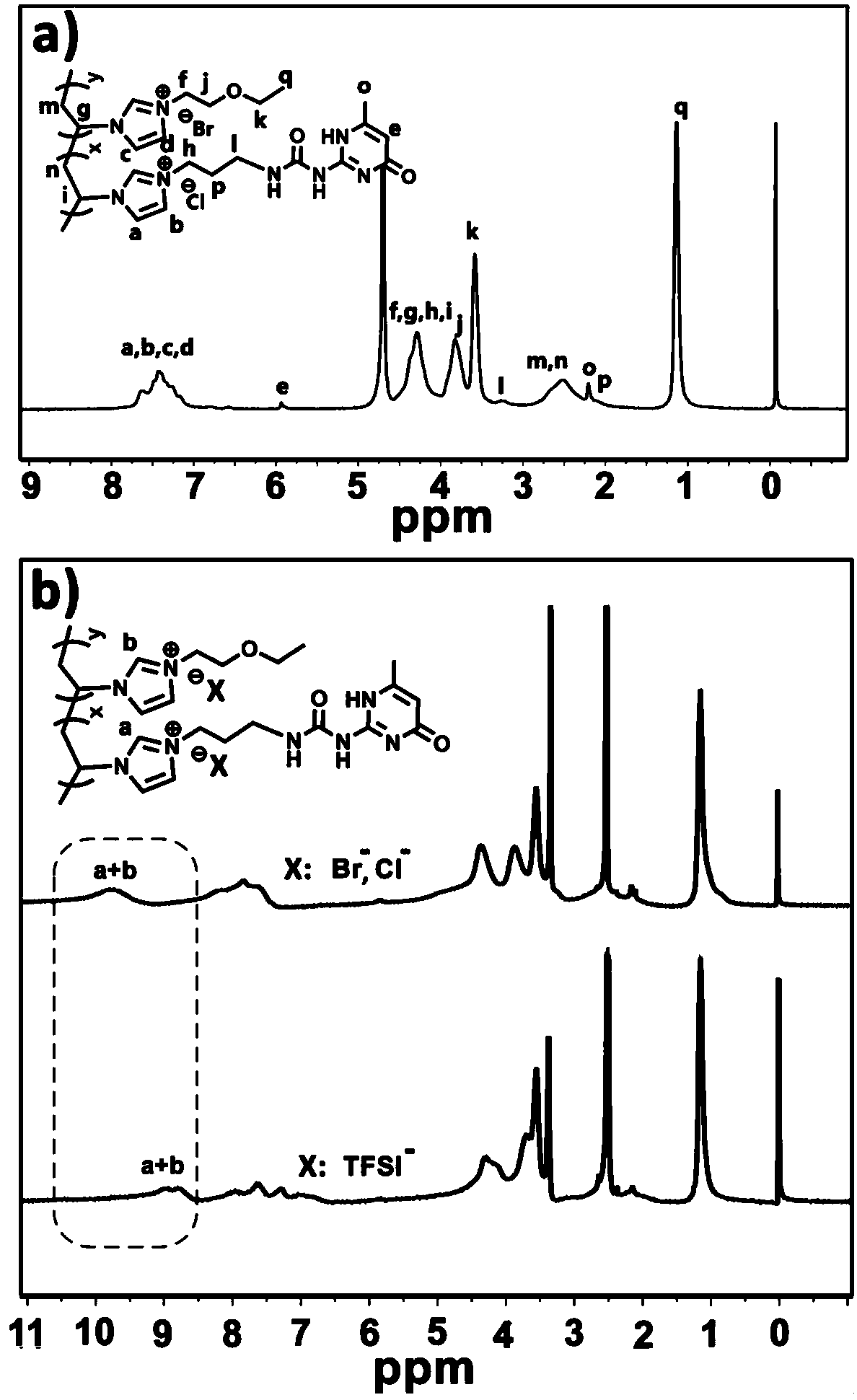

[0028] Preparation of ionic liquid monomer 1-[1-(3-chloropropyl)-2-ureido-4[1H]pyrimidinone]-3-vinylimidazolium chloride salt (IL-UPy) The above-mentioned monomer A): using 1-vinylimidazole and 1-(3-chloropropyl)-2-ureido-4[1H]pyrimidinone (abbreviated as: 3-chloropropyl-UPy) through quaternary ammonium produced by chemical reaction. The details are as follows: 1-vinylimidazole (4.71g, 0.050mol), 3-chloropropyl-UPy (2.45g, 0.010mol) and DMF (6mL) were added to a 100mL round bottom flask, refluxed at 80°C Reaction 72h. Then, the reactant was added dropwise to diethyl ether, the product was precipitated, and excess 1-vinylimidazole and solvent DMF were removed, washed with diethyl ether several times, and the obtained crude product was vacuum-dried at 60°C for 24h, and then again Soluble in water. The solution w...

Embodiment 2

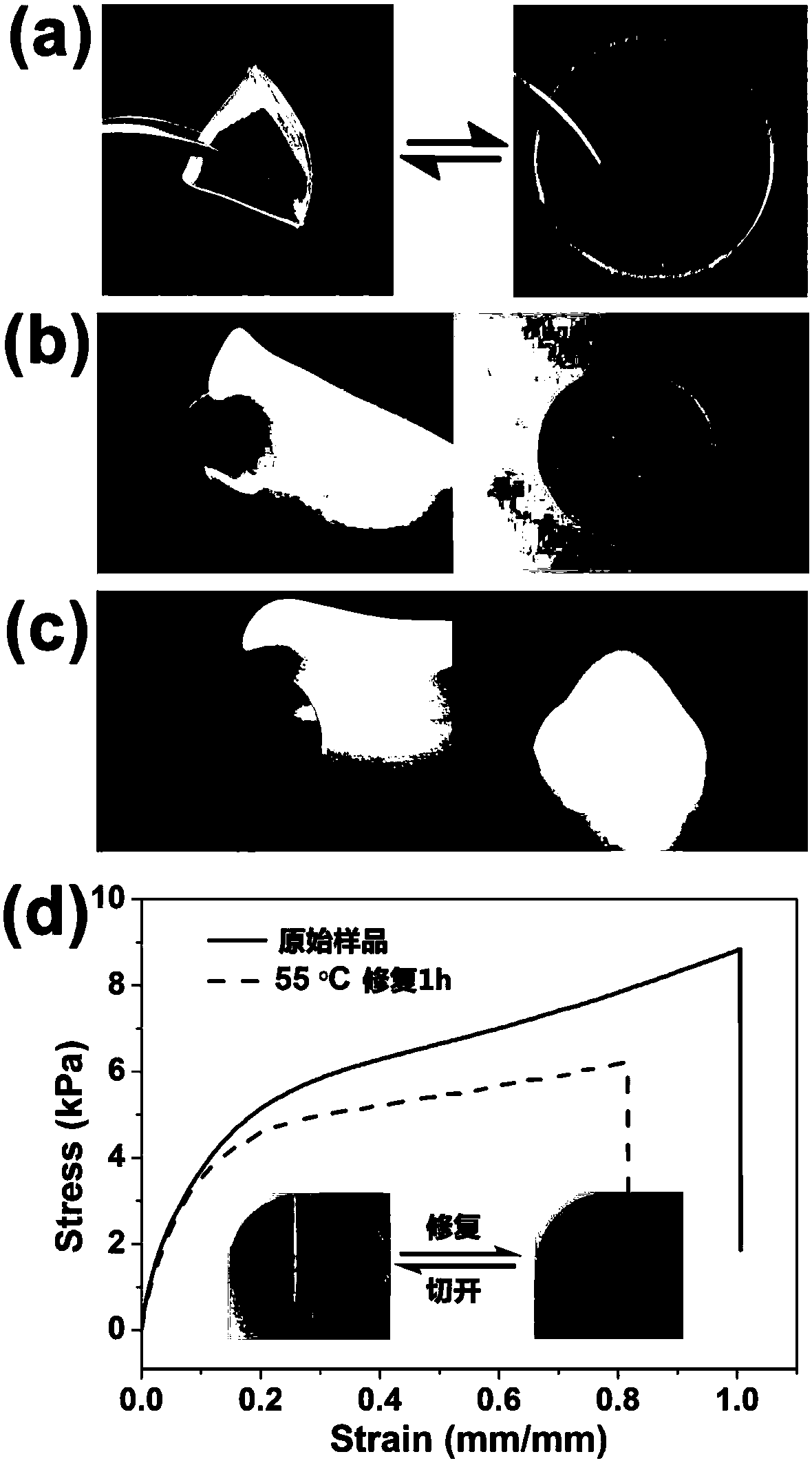

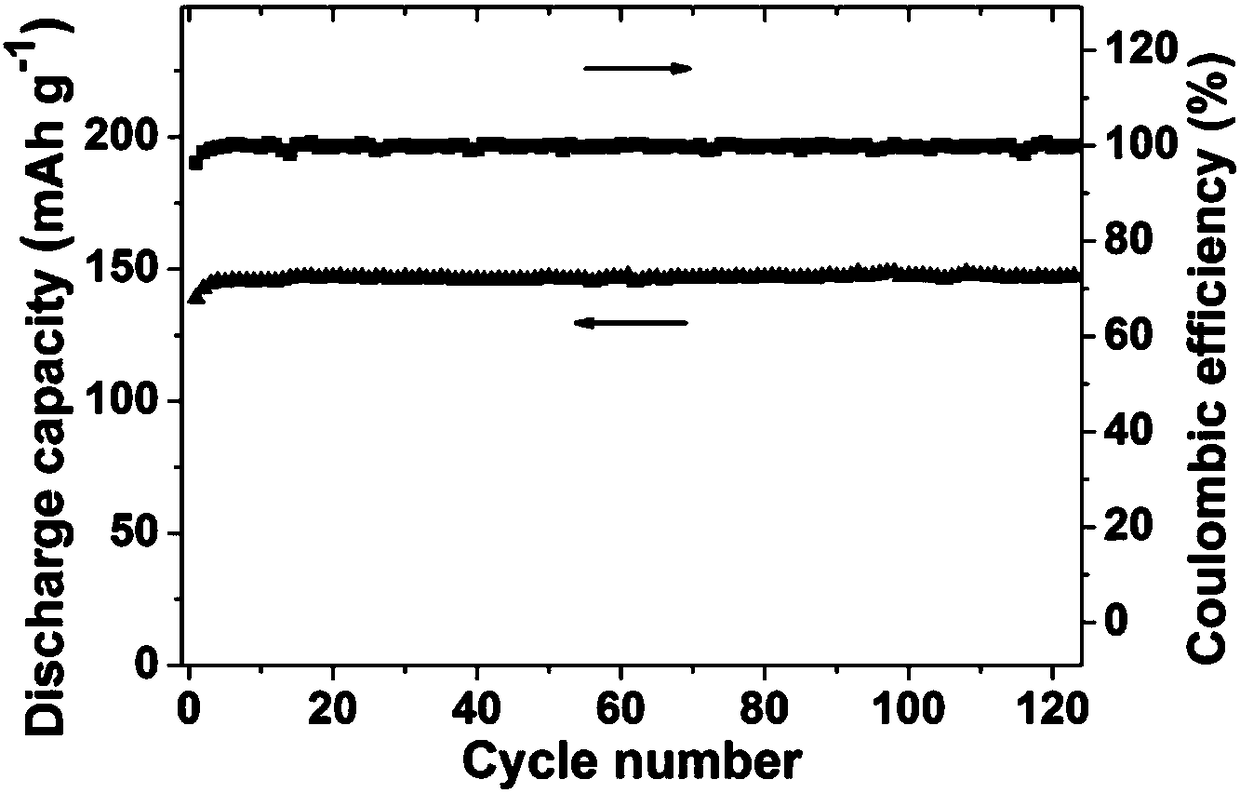

[0035] Test of repair performance of self-healing ion gel electrolyte in battery: assembly and performance test of lithium battery: including weighing LiFePO 4 (8.0mg), 1.0mg acetylene black and PVDF (1.0mg), and add N-methylpyrrolidone (17mg), stir well to get a well-mixed slurry; then scrape it on a clean aluminum foil , dried to a constant weight at 80 °C under a vacuum of 0.015 MPa, and rolled into LiFePO under a pressure of 10 MPa. 4 electrode, and cut into a positive electrode disc, and the lithium sheet was used as the negative electrode. The ion gel electrolyte in the embodiment (1) is cut open, the cut surfaces are contacted, and assembled into LiFePO 4 / Li button battery, and then place the battery at 55°C, let the damaged ion gel electrolyte layer repair for 1h, disassemble the battery and find that the gel electrolyte has been well repaired, as Figure 4 as shown in a. At a rate of 0.2C (voltage range 2.5-4V), the charge-discharge cycle test was performed on the...

Embodiment 3

[0037] Preparation of 1-(5-pentanamide)-3-vinylimidazolium chloride salt (IL-Am) ionic liquid monomer: it is prepared by quaternization reaction using 1-vinylimidazole and 5-chloropentanamide. The details are as follows: 1-vinylimidazole (5.64g, 0.060mol), 5-chloropentanamide (4.07g, 0.030mol) and DMF (6mL) were added into a round bottom flask, condensed and refluxed at 85°C for 48h. Then, the reactant was added dropwise to diethyl ether to precipitate the product, and the excess 1-vinylimidazole and solvent DMF were removed, washed several times with diethyl ether, and then washed with acetone, and the obtained crude product was vacuum-treated at 60°C. Dry for 24h, then dissolve in water again. The solution was filtered and the filtrate was collected (to remove excess 3-chloropropyl-UPy), and the filtrate was further lyophilized to obtain the final product.

[0038] The preparation of 1-(2-ethyl ether)-3-vinylimidazolium bromide (IL-Ether) ionic liquid monomer: first, 2-brom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com