Erosion morphology test method of thermal barrier coating based on terahertz technology

A technology of thermal barrier coatings and testing methods, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as errors, changes in the refractive index of ceramic layers, and reduce convenience, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

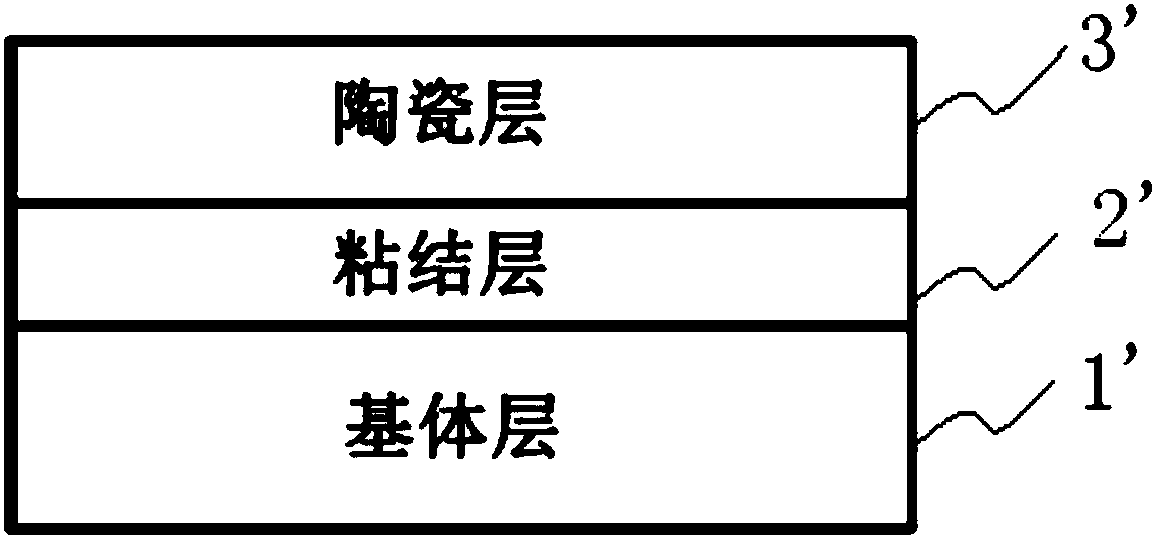

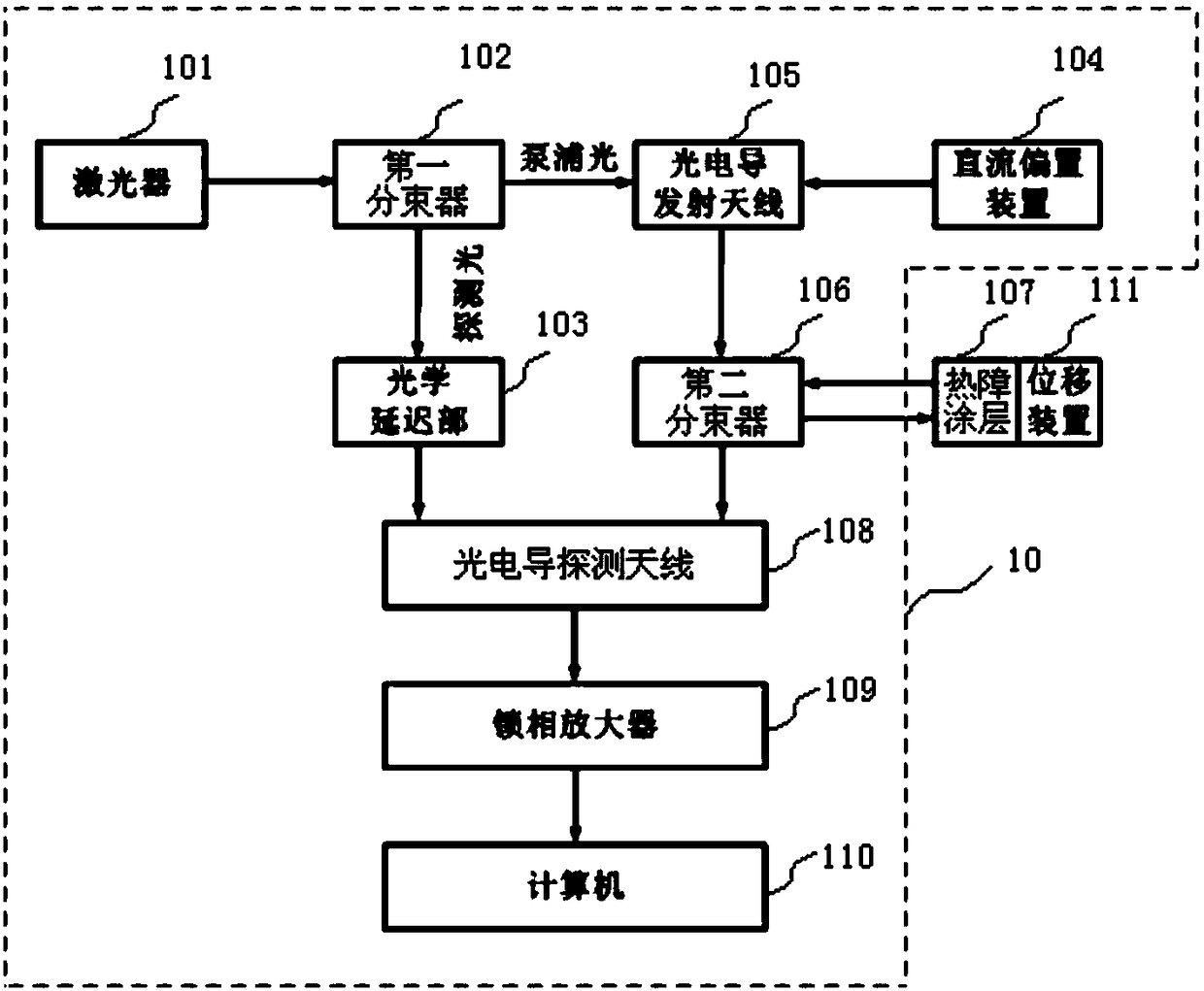

[0032]Terahertz usually refers to electromagnetic radiation with a frequency of 0.1-10THz and a wavelength range of 0.03-3mm, which is between radio waves and light waves. In the optical field, terahertz is also called far-infrared rays. Because terahertz has the characteristics of high frequency, short pulse, high resolution and low photon energy, and has the advantages of safety, efficiency, non-contact and non-destructive compared with traditional detection methods, as a new technology, it is currently widely used in the field of non-destructive testing. In view of the structural characteristics of thermal barrier coatings, the top ceramic layer is a dielectric material, the middle metal bonding layer and the protected base layer are all conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com