High waterproofing lap type locking screw steel plate

A technology with high water resistance and steel plates, which is applied to roofs, roofs, buildings, etc. that use flat/curved panels. It can solve problems that affect the strength of metal plates, generate capillarity, and easily damage the board surface, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

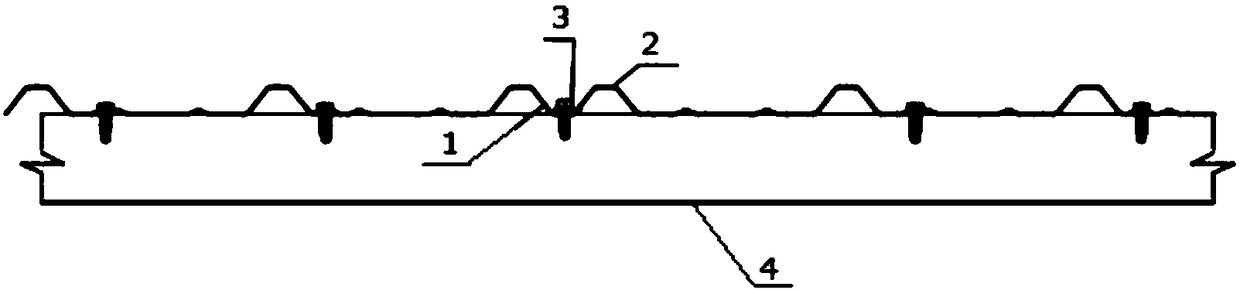

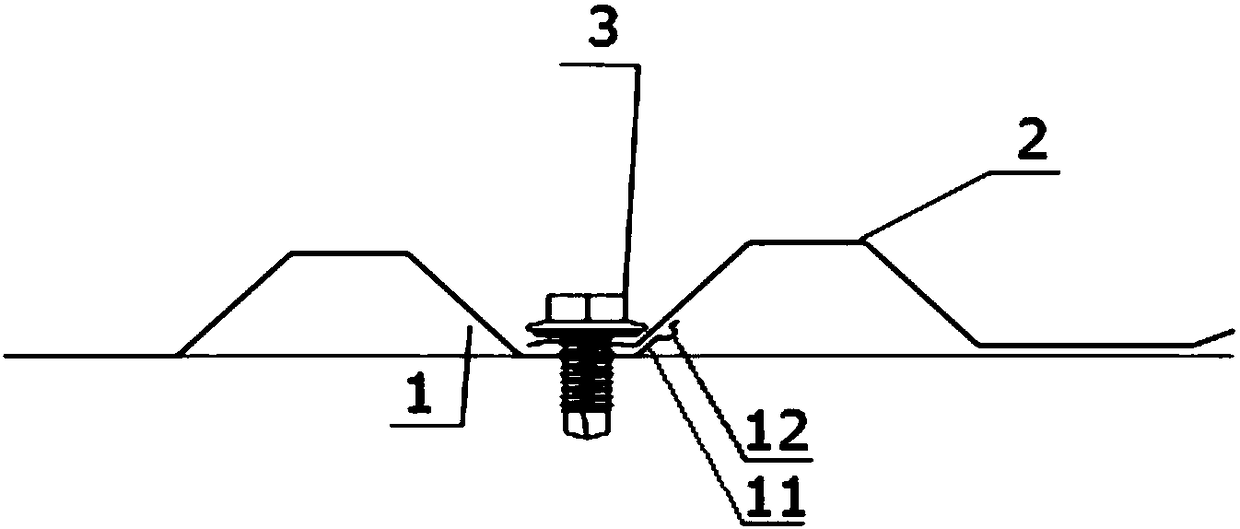

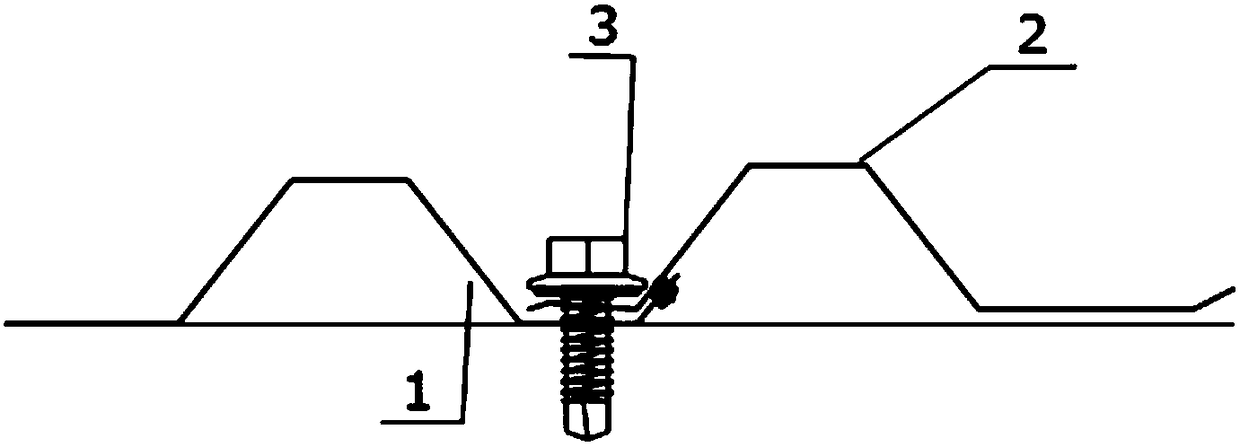

[0025] A highly waterproof lap-joint lock screw steel plate, including a male rib 1 and a female rib 2, the male rib 1 and the female rib 2 are respectively arranged at both ends of the steel plate, and the overlap between the male rib 1 and the female rib 2 is passed through a self-tapping screw 3 Fastened to the purlin 4, the end of the male rib 1 has a bend 11, and the bend 11 has a water stop groove 12, and the water stop groove 12 is arranged in a direction parallel to the male rib 1 and the female rib 2, that is, parallel to the steel plate In the direction of the longitudinal embossing, the water stop groove 12 is filled with sealing material, and the sealing material is attached to the female rib 2 .

[0026] The sealing material is butyl sealant, and the water stop groove 12 is an arc groove. The steel plate of this embodiment can achieve 100% waterproof effect after 24 hours of water storage test after installation, and can be used as a roof panel with a large slope....

Embodiment 2

[0029] The difference from Embodiment 1 is that the sealing material in the water stop groove 12 is sealing tape, and the rest are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com