Preparation method of textile deepening agent

A darkening agent, textile technology, applied in the field of preparation of textile darkening agent, can solve problems such as poor darkening effect, reduce fabric color fastness, etc., achieve improved darkening efficiency, excellent color fixing effect, and improve stable dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

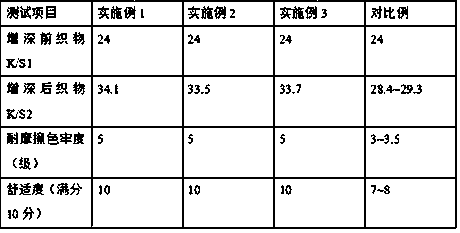

Examples

preparation example Construction

[0015] A preparation method of a textile darkening agent, comprising the steps of:

[0016] (1) Take 1,3-propanediol and add adipic acid in a mass ratio of 13:10 to mix, stir and mix at 50~55°C for 30~40min, then add p-toluenesulfonic acid with 0.8~1.2% adipic acid mass, and heat up to Stir and mix at 100~105°C for 1~2h, then keep warm at -0.1MPa, 120~130°C for 2~3h to obtain a stirred mixture, take the stirred mixture and add chloroform and distilled water in a mass ratio of 1:5:5, mix and let stand 3~4h, take off the lower layer liquid and distill under reduced pressure, dry to obtain the dried product;

[0017] (2) Take the dry matter and add isophorone diisocyanate according to the mass ratio of 15~18:9~12, stir and mix at 45~50°C for 40~50min, then add dibutyltin dilaurate with a dry matter mass of 0.04~0.07% , stir and mix at 45~50°C for 15~20min, then raise the temperature to 65~70°C and keep it warm for 2~3h to obtain the mixture. Take the mixture and add 2,2-dimethyl...

Embodiment 1

[0022] A preparation method of a textile darkening agent, comprising the steps of:

[0023] (1) Take 1,3-propanediol and add adipic acid in a mass ratio of 13:10 to mix, stir and mix at 50°C for 30 minutes, then add p-toluenesulfonic acid with 0.8% adipic acid mass, heat up to 100°C, stir and mix for 1 hour, Then keep it at -0.1MPa and 120°C for 2 hours to obtain a stirred mixture. Take the stirred mixture and add chloroform and distilled water in a mass ratio of 1:5:5 to mix, let it stand for 3 hours, take the lower layer liquid and distill it under reduced pressure, and dry it to obtain a dry product. ;

[0024] (2) Take the dry matter and add isophorone diisocyanate at a mass ratio of 15:9, stir and mix at 45°C for 40 minutes, then add dibutyltin dilaurate with a dry matter mass of 0.04%, stir and mix at 45°C for 15 minutes, and then heat up Incubate at 65°C for 2 hours to obtain a mixture. Take the mixture and add 2,2-dimethylolpropionic acid at a mass ratio of 20:1, and ...

Embodiment 2

[0029] A preparation method of a textile darkening agent, comprising the steps of:

[0030] (1) Take 1,3-propanediol and add adipic acid in a mass ratio of 13:10 to mix, stir and mix at 55°C for 40 minutes, then add p-toluenesulfonic acid with 1.2% adipic acid mass, heat up to 105°C, stir and mix for 2 hours, Then keep it at -0.1MPa and 130°C for 3 hours to obtain a stirred mixture. Take the stirred mixture and add chloroform and distilled water in a mass ratio of 1:5:5 to mix, let it stand for 4 hours, take the lower layer liquid and distill it under reduced pressure, and dry it to obtain a dry product. ;

[0031] (2) Take the dry matter and add isophorone diisocyanate at a mass ratio of 18:12, stir and mix at 50°C for 50 minutes, then add dibutyltin dilaurate with a dry matter mass of 0.07%, stir and mix at 50°C for 20 minutes, and then heat up Incubate at 70°C for 3 hours to obtain a mixture. Take the mixture and add 2,2-dimethylolpropionic acid at a mass ratio of 20:1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com