5-series aluminum alloy panel, as well as preparation method and application thereof

An aluminum alloy plate and aluminum alloy plate technology, applied in the field of aluminum alloy materials, can solve the problems of shortening cooling time, no special requirements for cooling speed, unsatisfactory cooling effect, etc., and achieve the effect of good plasticity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

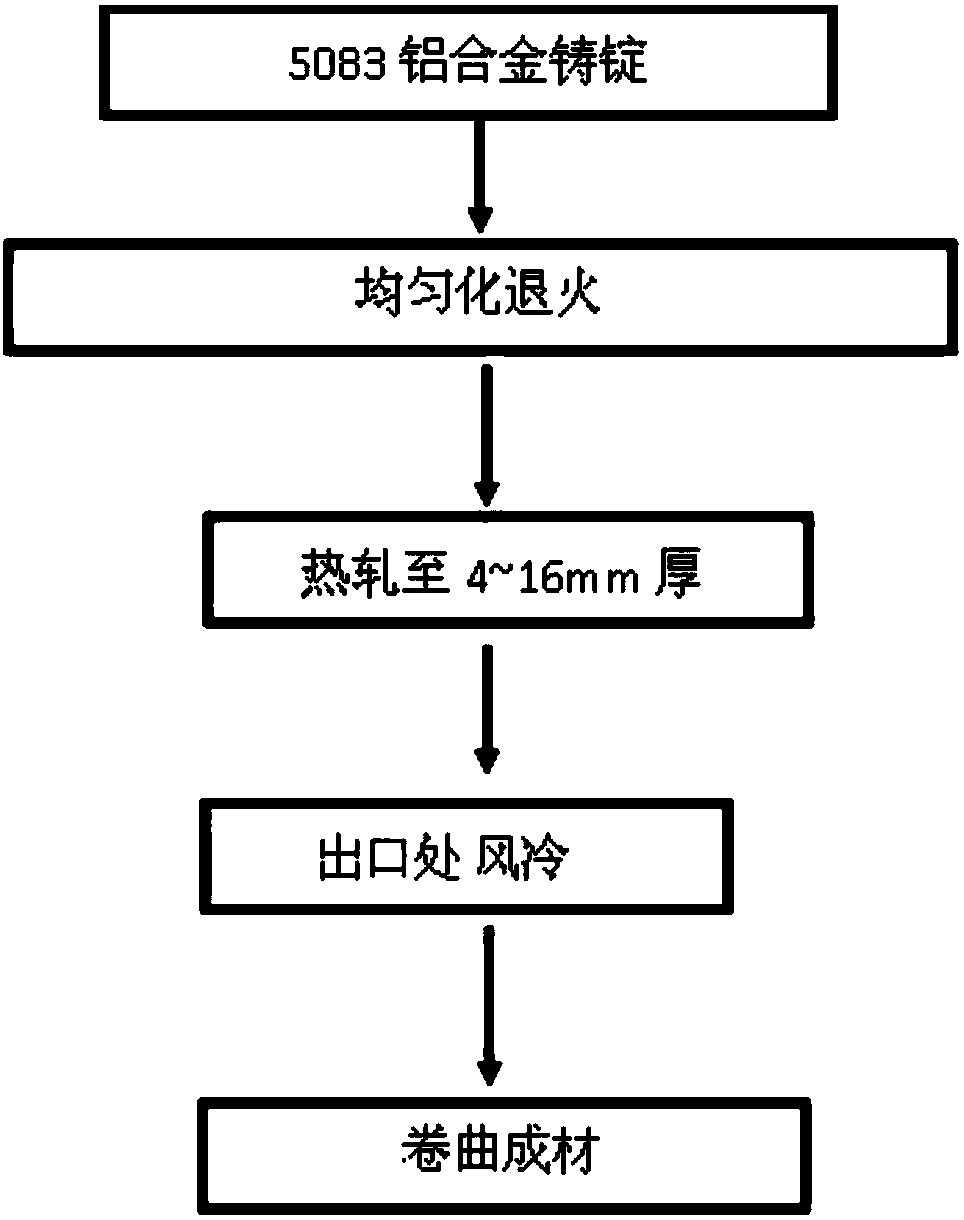

[0024] This embodiment provides a method for preparing a 5-series aluminum alloy, including:

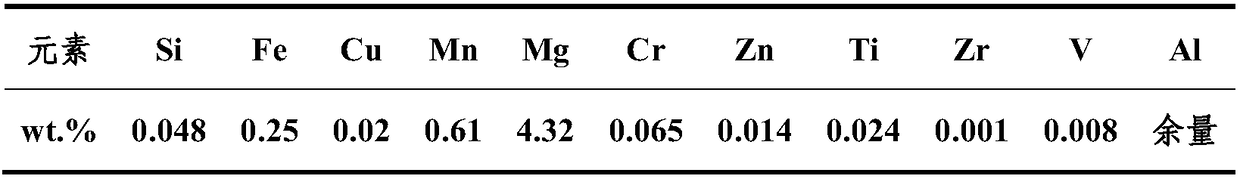

[0025] (1) A 400mm thick flat ingot of 5083 aluminum alloy was obtained by melting and casting. The composition is shown in Table 1. It was uniformly annealed at 500°C for 48 hours, and the surfaces of the ingot were milled flat.

[0026] (2) Heat the cast ingot to 420° C. and then hot-roll it to a thickness of 4 mm.

[0027] (3) Use a blower to cool the 5083 plate at the exit of the hot rolling at a cooling rate of 15°C / s, and the plate after cooling to 200°C is curled into a material.

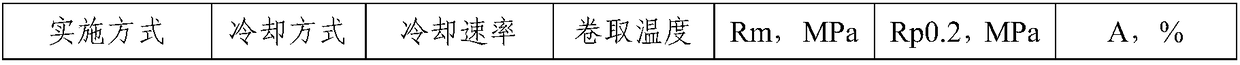

[0028] (4) The tensile test of the obtained 5083 plate is carried out according to GB / T228.1-2010, and the measured tensile properties are shown in Table 2.

Embodiment 2

[0030] This embodiment provides a method for preparing a 5-series aluminum alloy, including:

[0031] (1) A 400mm thick flat ingot of 5083 aluminum alloy was obtained by melting and casting. The composition is shown in Table 1. It was uniformly annealed at 500°C for 48 hours, and the surfaces of the ingot were milled flat.

[0032] (2) Heat the cast ingot to 420° C. and then hot-roll it to a thickness of 4 mm.

[0033] (3) Use a blower to cool the 5083 plate at the exit of the hot rolling. The measured cooling rate of the plate is 20°C / s, and the plate is curled into a material after cooling to 190°C.

[0034] (4) The tensile test of the obtained 5083 plate is carried out according to GB / T228.1-2010, and the measured tensile properties are shown in Table 2.

Embodiment 3

[0036] This embodiment provides a method for preparing a 5-series aluminum alloy, including:

[0037] (1) A 400mm thick flat ingot of 5083 aluminum alloy was obtained by melting and casting. The composition is shown in Table 1. It was uniformly annealed at 500°C for 48 hours, and the surfaces of the ingot were milled flat.

[0038] (2) Heat the cast ingot to 420°C and hot-roll it to a thickness of 16mm.

[0039] (3) Use a blower to cool the 5083 plate at the exit of the hot rolling. The measured cooling rate of the plate is 25°C / s, and the plate is curled into a material after cooling to 200°C.

[0040] (4) The tensile test of the obtained 5083 plate is carried out according to GB / T228.1-2010, and the measured tensile properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com