Drilling plugging fluid and preparation method thereof

A plugging fluid and drilling technology, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of leakage and the lack of sufficient strength of the plugging fluid, and achieves strong thixotropy, which is beneficial to environmental protection and durable. Good temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

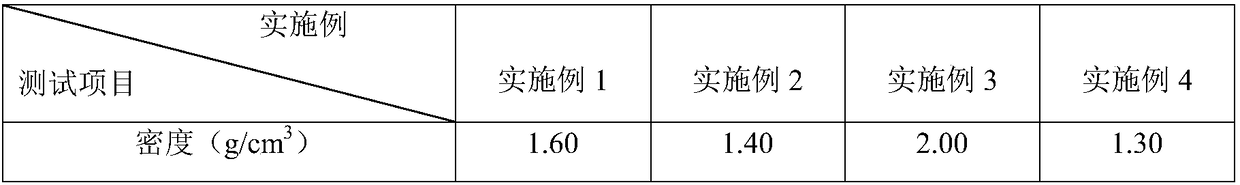

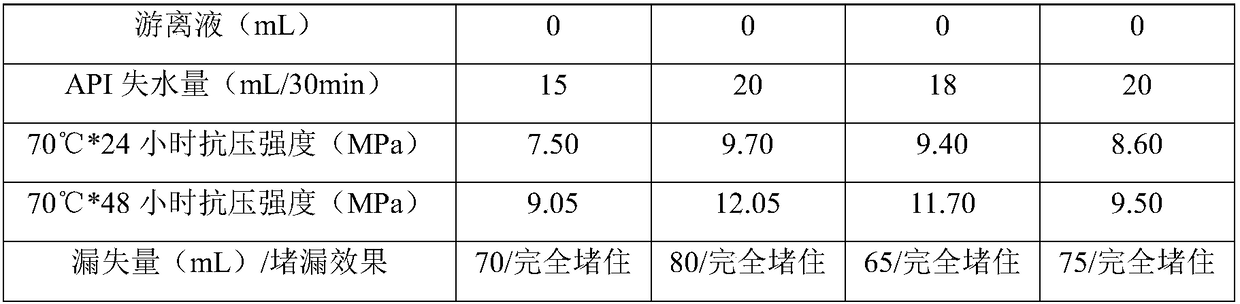

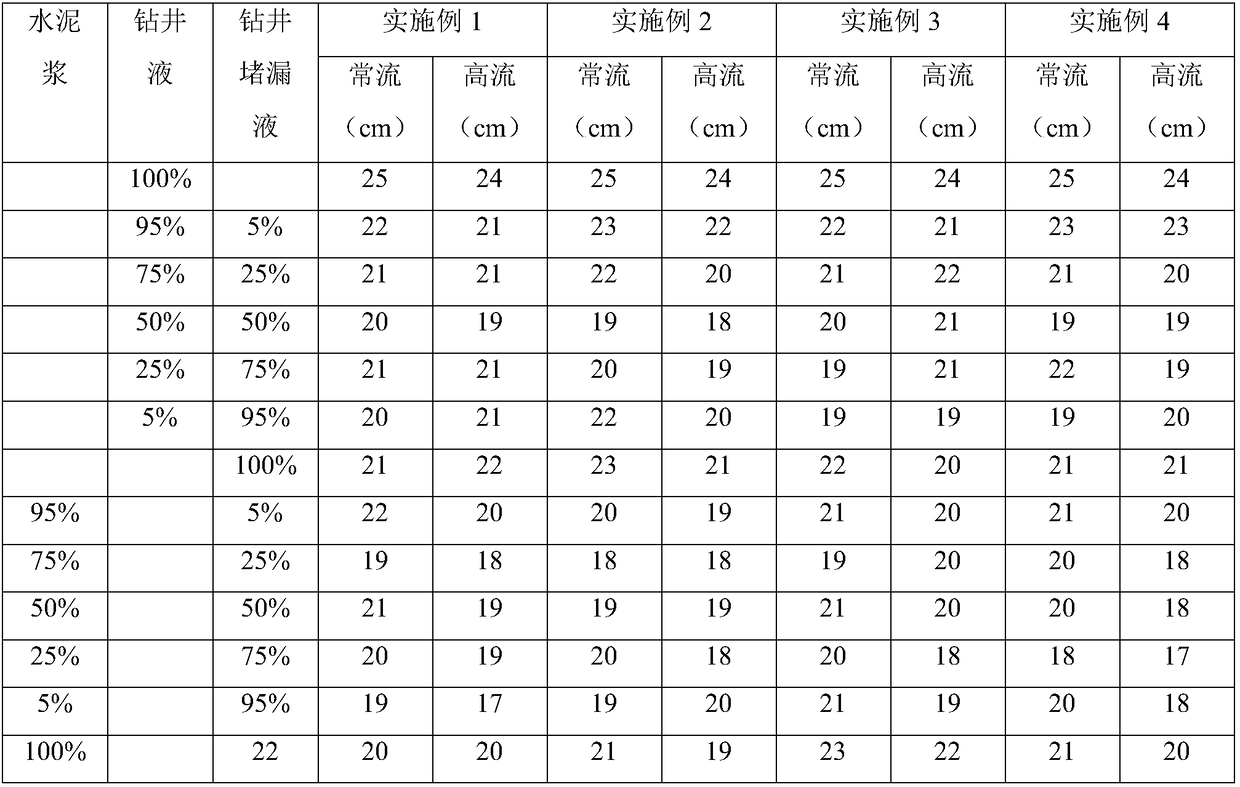

Examples

Embodiment 1

[0020] (1) Preparation of modified flax fiber

[0021] Put the flax fiber with a length of 2mm into the chamber of the low-temperature plasma processing instrument, turn on the vacuum pump, and press the pressure of 45cm when the vacuum degree in the chamber is less than 10Pa. 3 Oxygen was fed at a flow rate of 1 / min, and the flax fiber was modified by low-temperature plasma after adjusting the high-frequency power supply to 120w, and the modification time was 60s.

[0022] (2) Preparation of drilling plugging fluid

[0023] Add 100 parts of CaO to 100 parts of water successively, the content of CaO>10wt%, SiO 2 content>40wt% and fineness is 200-325 mesh nickel slag (curing agent), 1 part of modified flax fiber (bridging agent) prepared in step (1), 1 part of hydroxypropyl methylcellulose (suspension Stabilizer), 0.5 parts of sodium tetraborate (retarder), 2 parts of activator (mixed by sodium hydroxide, sodium carbonate, sodium sulfate and sodium silicate in a mass ratio of...

Embodiment 2

[0025] (1) Preparation of modified flax fiber

[0026] Put the flax fiber with a length of 1mm into the chamber of the low-temperature plasma treatment instrument, turn on the vacuum pump, and press the pressure of 40cm when the vacuum degree in the chamber is 3 Oxygen was introduced at a flow rate of 1 / min, and the flax fiber was modified by low-temperature plasma after adjusting the high-frequency power supply to 100w, and the modification time was 100s.

[0027] (2) Preparation of drilling plugging fluid

[0028] Add 150 parts of CaO to 100 parts of water successively, the content of CaO>10wt%, SiO 2 content>40wt% and fineness is 200-325 purpose nickel slag (curing agent), 10 parts of modified flax fibers (bridging agent) prepared in step (1), 2 parts of hydroxypropyl methylcellulose (suspension Stabilizer), 5 parts of sodium polyphosphate (retarder), 10 parts of activator (by mixing sodium hydroxide, sodium carbonate, sodium sulfate and sodium silicate in a mass ratio of ...

Embodiment 3

[0030] (1) Preparation of modified flax fiber

[0031] Put the flax fiber with a length of 0.5mm into the chamber of the low-temperature plasma processing instrument, turn on the vacuum pump, and press 50cm when the vacuum degree in the chamber is less than 10Pa. 3 Oxygen was introduced at a flow rate of / min, and the low-temperature plasma modification of the flax fiber was started after adjusting the high-frequency power supply to 80w, and the modification time was 300s.

[0032] (2) Preparation of drilling plugging fluid

[0033] Add 60 parts of CaO to 100 parts of water successively, the content of CaO>10wt%, SiO 2 content>40wt% and fineness is 200-325 purpose nickel slag (solidifying agent), the modified flax fiber (bridging agent) prepared in 8 parts of step (1), 0.5 part of hydroxypropyl methylcellulose (suspension Stabilizer), 2 parts of sodium dihydrogen phosphate (retarder), 8 parts of activator (mixed by sodium hydroxide, sodium carbonate, sodium sulfate and sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com