Rust removal equipment for machining

A mechanical processing and equipment technology, applied in the field of mechanical processing rust removal equipment, can solve problems such as affecting the use effect of mechanical parts, powder easily adhering to mechanical parts, and damage to the outer surface of mechanical parts, so as to improve the rust removal effect and reduce Physical labor, injury avoidance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

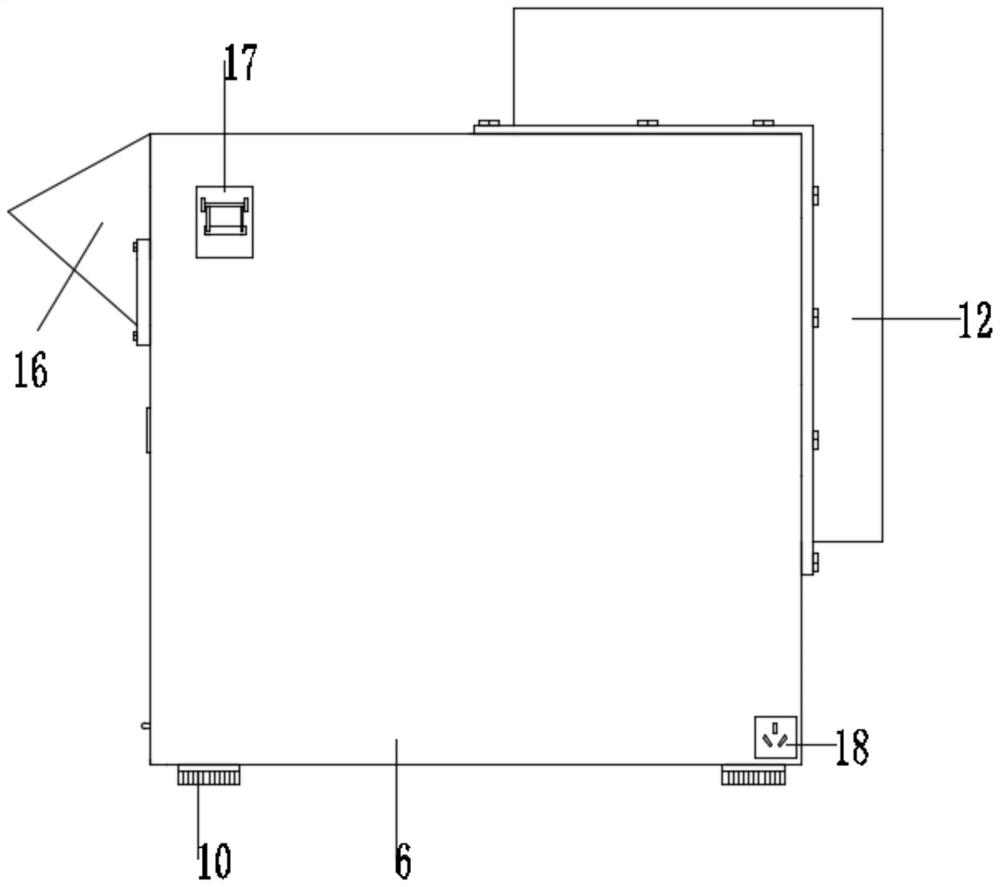

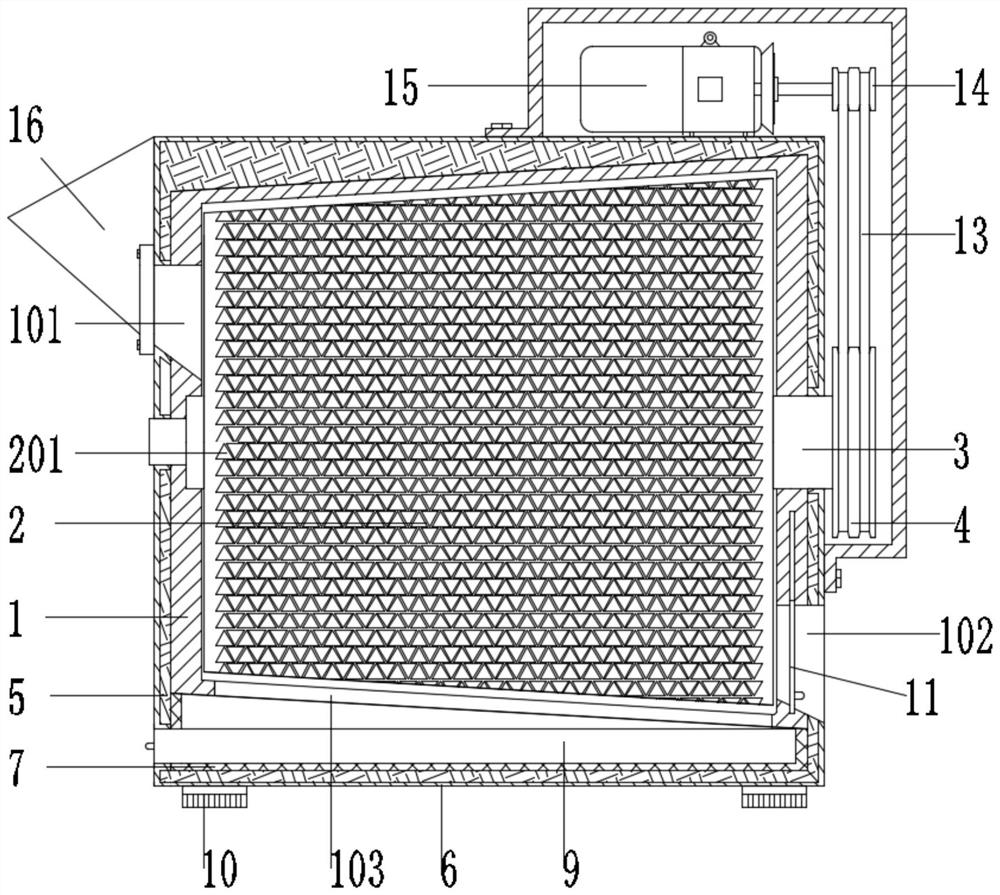

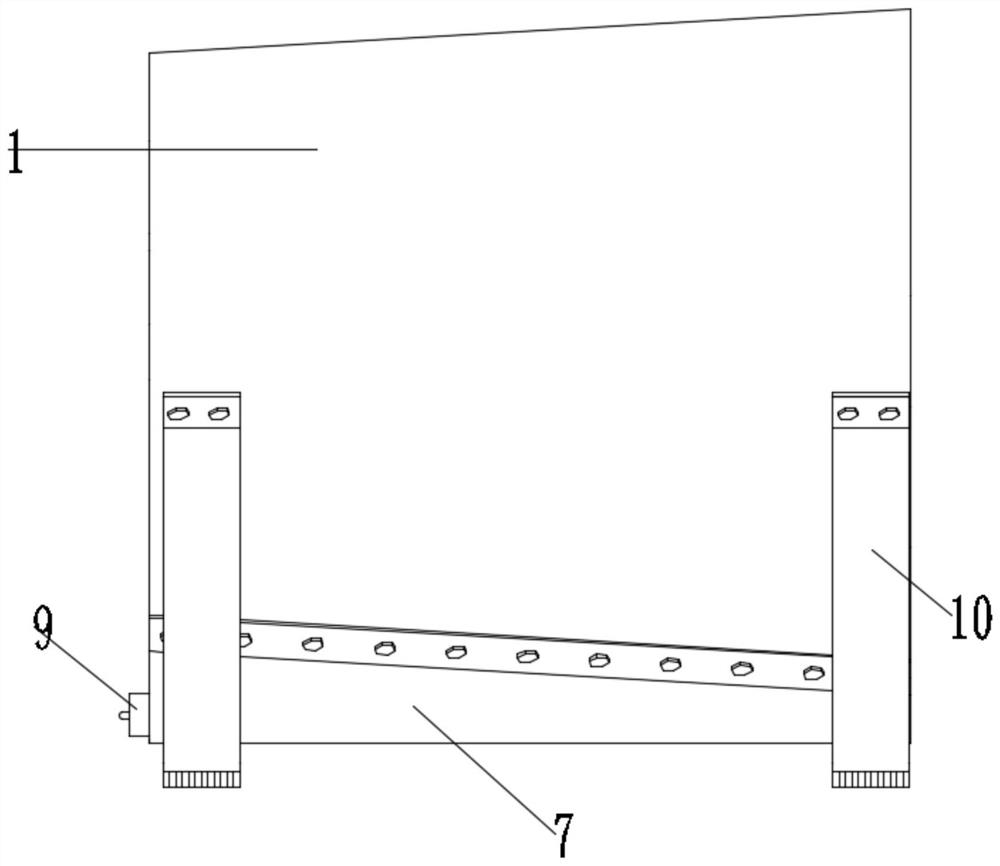

[0036] as attached figure 1 to attach Figure 9 Shown:

[0037]The present invention provides a kind of derusting equipment for mechanical processing, comprising a derusting inner cylinder 1, a feed hole 101, a discharge hole 102, a rust leaking hole 103, a derusting drum 2, a screen hole 201, a rotating shaft 3, a Drive wheel 4, sound insulation cotton 5, shell 6, rust storage rack 7, frosted ball 8, rust collection drawer 9, magnet sheet 901, support column 10, gate 11, protective cover 12, transmission belt 13, drive wheel 14, motor 15. Feed funnel 16, master control switch 17 and power plug 18, four supporting columns 10 are installed on the outer wall of the inner cylinder 1 for derusting, and a feeding hole 101 is opened on the top of the left end surface of the inner cylinder 1 for derusting, and The feed hole 101 communicates with the bottom of the feed funnel 16, and a discharge hole 102 is provided at the bottom of the right end surface of the derusting inner cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com