Wheel hub casting die with multiple runners

A technology for casting molds and hubs, which is used in casting molding equipment, molds, mold components, etc., can solve the problems of slow solidification, waste of resources, and reduced utilization of molten metal, and achieves easy cooling and solidification. The effect of shrinking and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

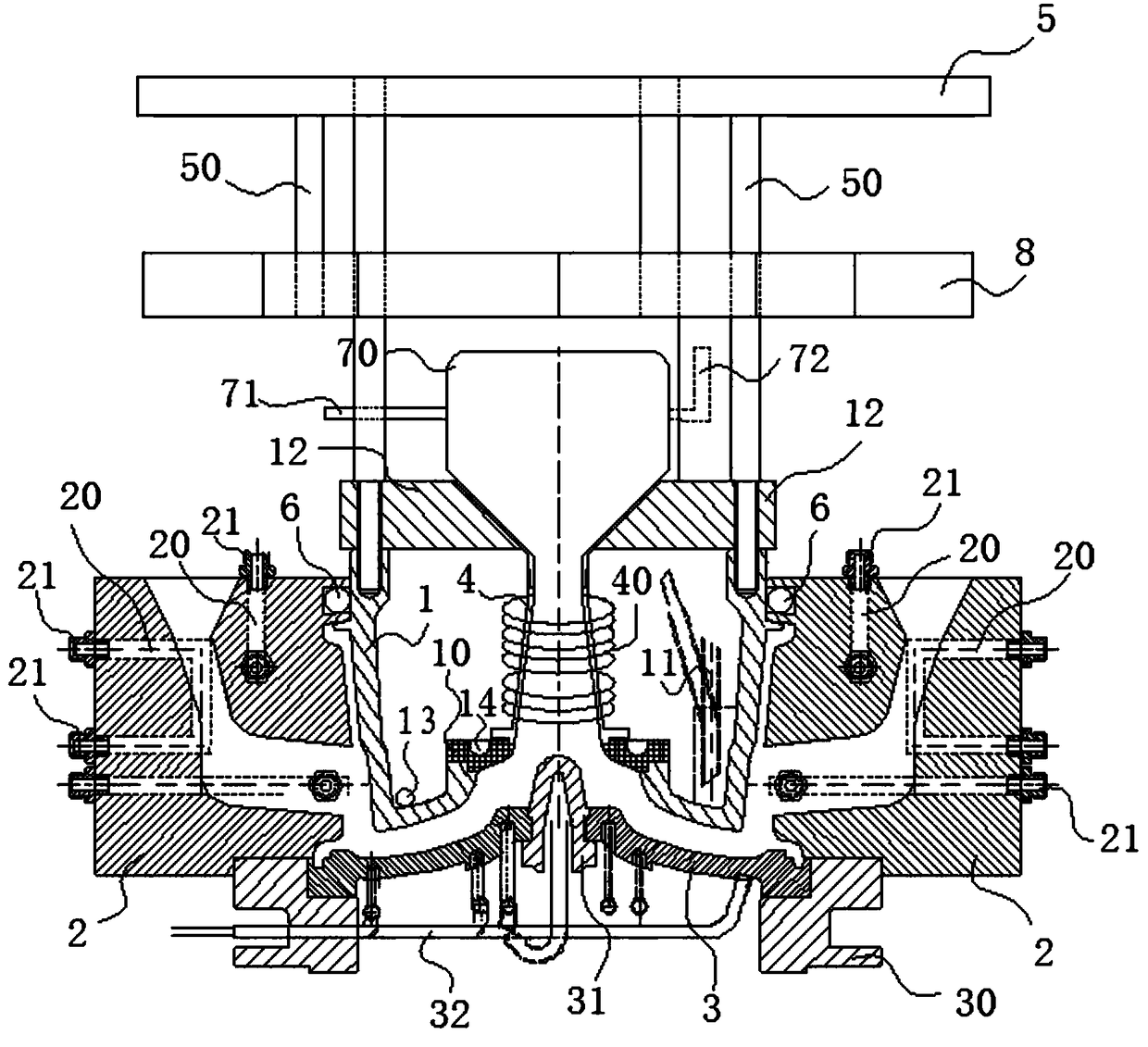

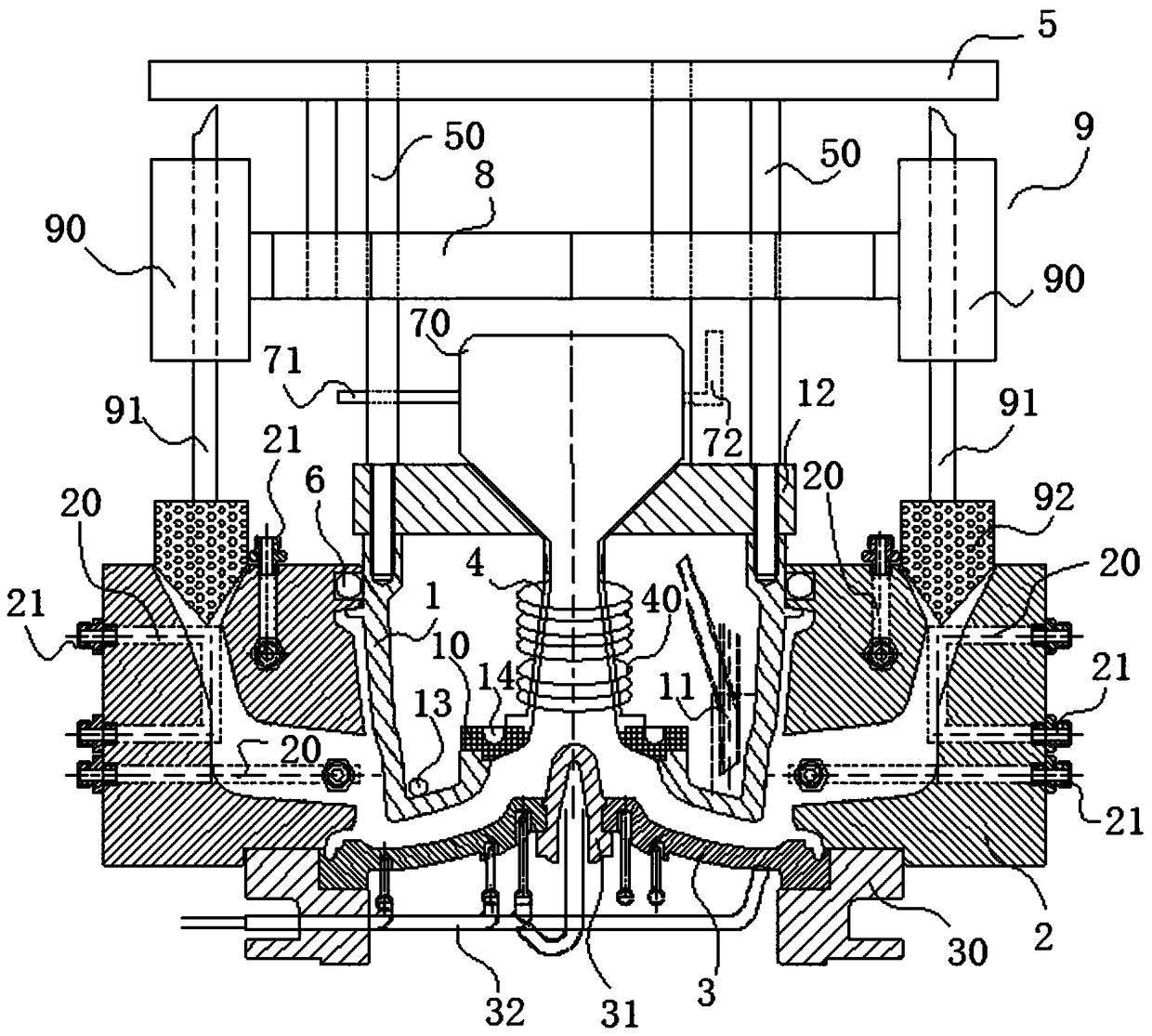

[0035] like figure 1 , figure 2 As shown, the present invention provides a wheel hub casting mold with a plurality of runners, which is used for being installed on a casting machine for casting a wheel hub, comprising: an upper mold 1, the upper mold 1 is connected to the upper machine plate 8 of the casting machine through connecting parts Connected; side mold 2, the side mold 2 is connected with the driving device of the side mold 2 of the casting machine; bottom mold 3, the bottom mold 3 is installed on the upper side of the casting machine table 30;

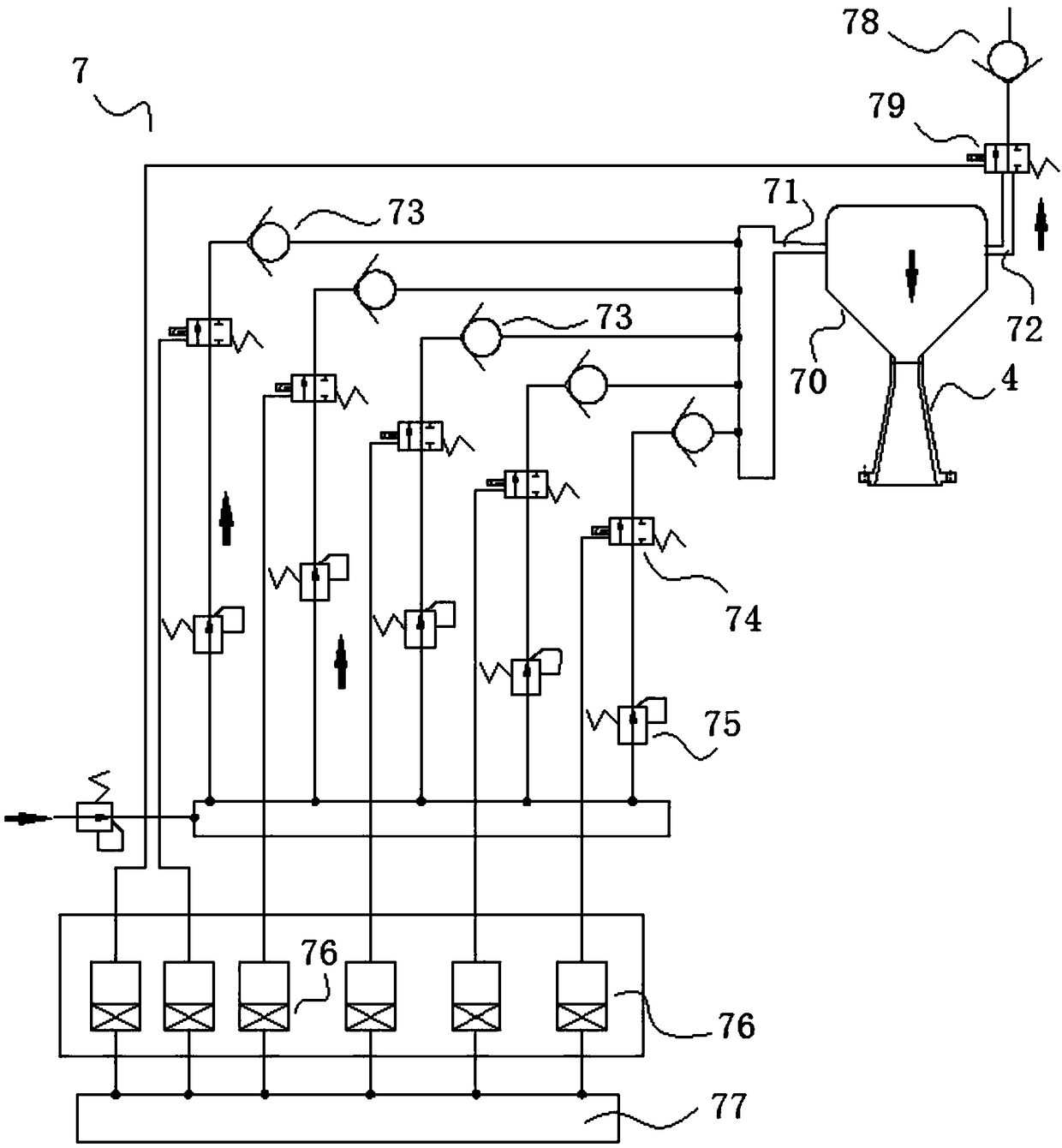

[0036] The driving device of the side mold 2 of the casting machine drives the side mold 2 to close the mold horizontally, and the driving device of the upper mold 1 of the casting machine drives the upper mold 1 to close the mold downward. The upper mold 1, the side mold 2 and the bottom mold 3 are formed after clamping. The casting cavity of the wheel hub to be cast; a liquid storage hopper 4 is connected to the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com