Preparation method of graphene macromoleclar polymer composite nanofiltration membrane

A technology of composite nanofiltration membrane and graphene polymer, which is applied in the field of preparation of graphene polymer composite nanofiltration membrane, can solve the problems of low membrane performance and use efficiency, low flux, and low salt interception rate, and achieve Increased rejection rate, improved membrane performance, and improved purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

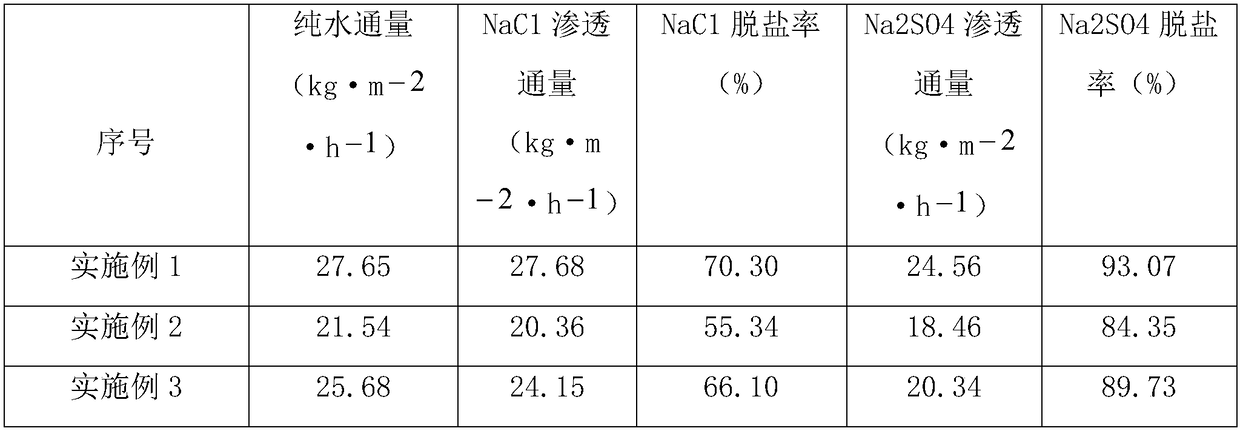

Examples

Embodiment 1

[0024] The invention provides a graphene polymer composite nanofiltration membrane, the preparation method of which is as follows:

[0025] Step 1: configure mixed acid, concentrated sulfuric acid (98%): concentrated phosphoric acid (85%) = 9: 1, put it in a container; take an appropriate amount of potassium permanganate;

[0026] Step 2: Take an appropriate amount of graphite, slowly pour the mixed acid along the wall of the cup into the container containing graphite;

[0027] Step 3: Place the above-mentioned mixed reactants in a magnetic stirring oil bath that has been preheated to 50°C, and slowly add potassium permanganate;

[0028] Step 4: After adding potassium permanganate, close the mouth of the container to prevent impurities from falling into the container. Then the reaction system was heated at 50° C. for 6 hours;

[0029] Step 5: Then, continue to add diluted hydrogen peroxide to the mixture while heating and stirring at 50°C. The standard of how much hydrogen p...

Embodiment 2

[0040] The invention provides a graphene polymer composite nanofiltration membrane, the preparation method of which is as follows:

[0041] Step 1: configure mixed acid, concentrated sulfuric acid (98%): concentrated phosphoric acid (85%) = 9: 1, put it in a container; take an appropriate amount of potassium permanganate;

[0042] Step 2: Take an appropriate amount of graphite, slowly pour the mixed acid along the wall of the cup into the container containing graphite;

[0043] Step 3: Place the above-mentioned mixed reactants in a magnetic stirring oil bath that has been preheated to 50°C, and slowly add potassium permanganate;

[0044] Step 4: After adding potassium permanganate, close the mouth of the container to prevent impurities from falling into the container. Then the reaction system was heated at 50° C. for 6 hours;

[0045] Step 5: Then, continue to add diluted hydrogen peroxide to the mixture while heating and stirring at 50°C. The standard of how much hydrogen p...

Embodiment 3

[0056] The invention provides a graphene polymer composite nanofiltration membrane, the preparation method of which is as follows:

[0057] Step 1: configure mixed acid, concentrated sulfuric acid (98%): concentrated phosphoric acid (85%) = 9: 1, put it in a container; take an appropriate amount of potassium permanganate;

[0058] Step 2: Take an appropriate amount of graphite, slowly pour the mixed acid along the wall of the cup into the container containing graphite;

[0059] Step 3: Place the above-mentioned mixed reactants in a magnetic stirring oil bath that has been preheated to 50°C, and slowly add potassium permanganate;

[0060] Step 4: After adding potassium permanganate, close the mouth of the container to prevent impurities from falling into the container. Then the reaction system was heated at 50° C. for 6 hours;

[0061] Step 5: Then, continue to add diluted hydrogen peroxide to the mixture while heating and stirring at 50°C. The standard of how much hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com