Application and preparation method of pure magnesium/coating composite

A composite material and coating technology, applied in coating, medical science, surgery, etc., can solve problems such as scarring and fistula obstruction, and achieve the effects of reducing expression, reducing scars, and inhibiting fibroblast proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 pure magnesium / HA coating composite material

[0037] a. Extrude pure magnesium into rods at 170°C and an extrusion ratio of 20, then cut them into discs with a diameter of 14.5mm and a thickness of 1mm, and use 320-800# sandpaper to polish the surface of the disc. All discs were ultrasonically cleaned in acetone, air dried and weighed.

[0038] b. Then use electrodeposition and conversion coating method to form HA coating, the electrolyte is 0.042mol / L (Ca(NO 3 ) 2 ) and 0.025mol / L (NH 4 h 2 PO 4 ) aqueous solution, the CA / P ratio is 1.67, the pH is 5.0, the electrolysis voltage is 3V, the deposition is 4h, and the coating thickness is 2μm.

[0039] SEM image of pure magnesium / HA coating figure 1 As shown, where Ai is 100 times and Aii is 1000 times.

Embodiment 2

[0040] Embodiment 2 pure magnesium / DCPD coating composite material

[0041] a. Extrude pure magnesium into rods at 180°C and an extrusion ratio of 25, then cut them into discs with a diameter of 14.5mm and a thickness of 1mm, and use 320-800# sandpaper to polish the surface of the disc. All discs were ultrasonically cleaned in acetone, air dried and weighed.

[0042] b. Then use electrodeposition and conversion coating method to form DCPD coating, the electrolyte is 3.1% disodium hydrogen phosphate (Na 2 HPO4) and 5.3% calcium nitrate (Ca(NO 3 ) 2 ) solution, deposition conditions: pH 3.5, deposition at 45°C for 3 hours, coating thickness of 3 μm.

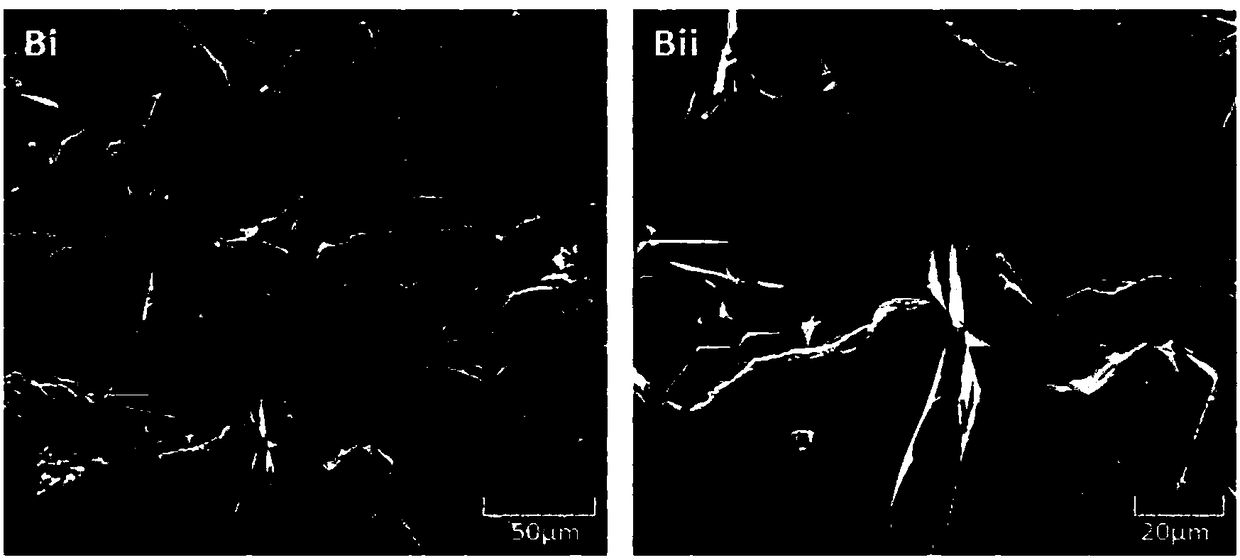

[0043] SEM image of pure magnesium / DCPD coating figure 2 shown. Among them, Bi is 400 times, and Bii is 1000 times.

[0044] HA and DCPD coatings are formed by chemical bonds between calcium phosphate and magnesium matrix.

Embodiment 3

[0045] Embodiment 3 pure magnesium / DCPD+SA coating composite material

[0046] a. The pure magnesium / DCPD coating composite material prepared in Example 2 is treated with stearic acid to form a pure magnesium / DCPD+SA coating composite material, soaked in 0.5mol / L stearic acid ethanol solution for 1.5h, DCPD The +SA coating depends on hydrogen bonding and physical adsorption, and the thickness of the DCPD+SA coating is 4 μm. .

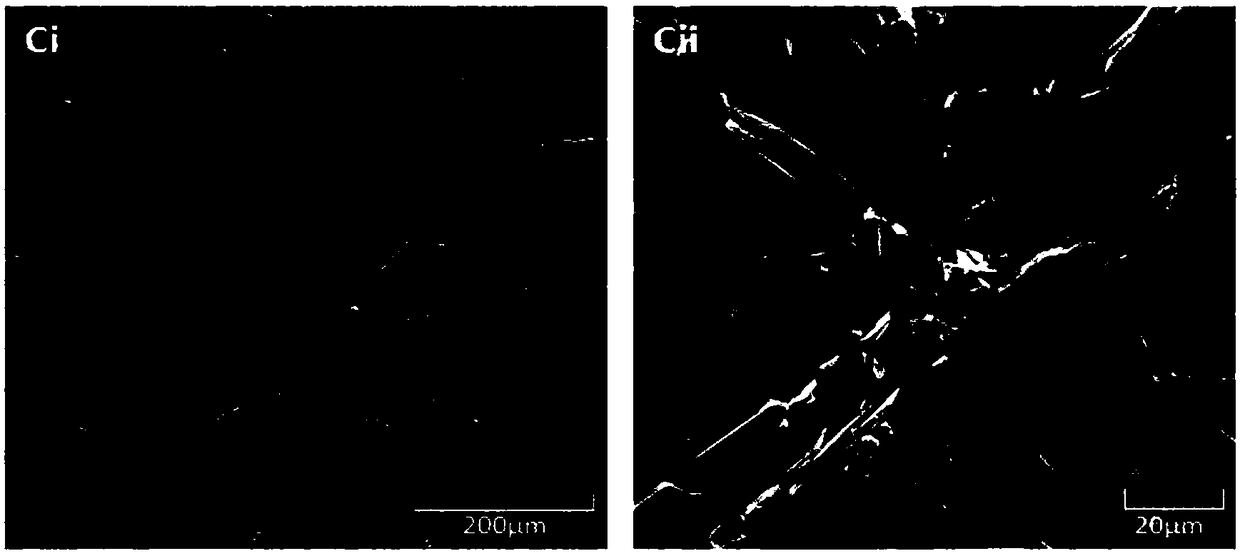

[0047] SEM image of pure magnesium / DCPD+SA coating image 3 shown. Among them, Ci is 100 times, and Cii is 1000 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com