Integrated iron-based decontamination and resource reuse microbial fuel cell and sewage treatment method

A fuel cell and microorganism technology, applied in biological water/sewage treatment, biochemical fuel cell, water/sludge/sewage treatment, etc., can solve the problems of difficult mining, high investment, high energy consumption, etc., and achieve significant economic benefits, High removal efficiency and guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in combination with specific drawings and specific embodiments. Unless otherwise stated or conflicted, the various preferred implementation modes can be combined arbitrarily.

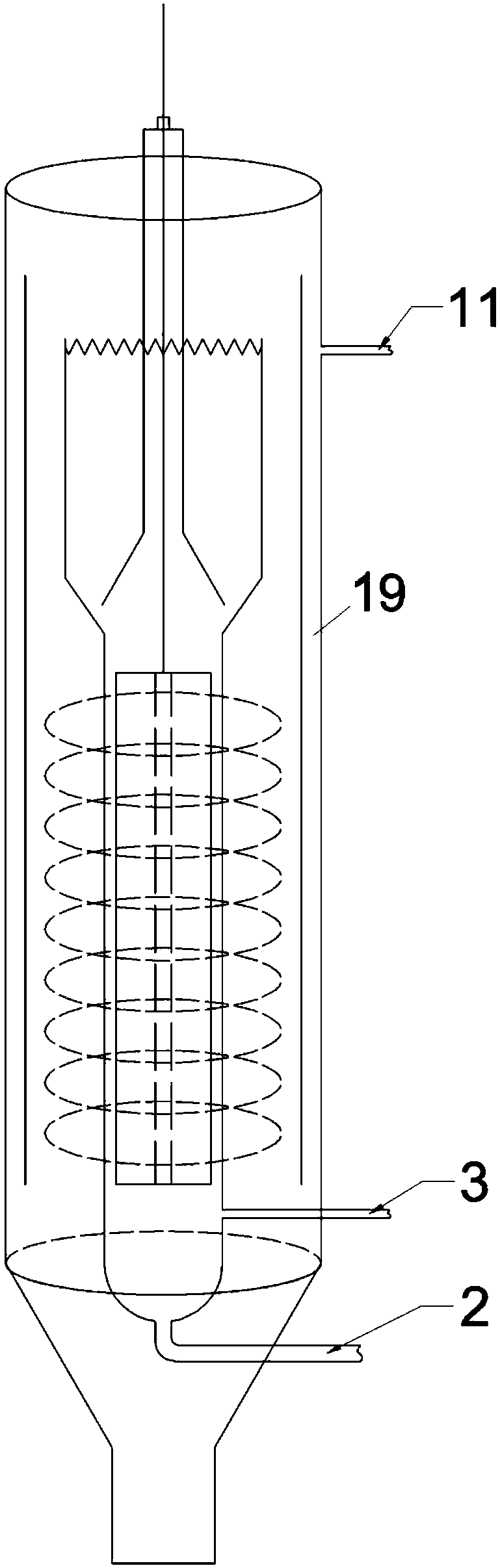

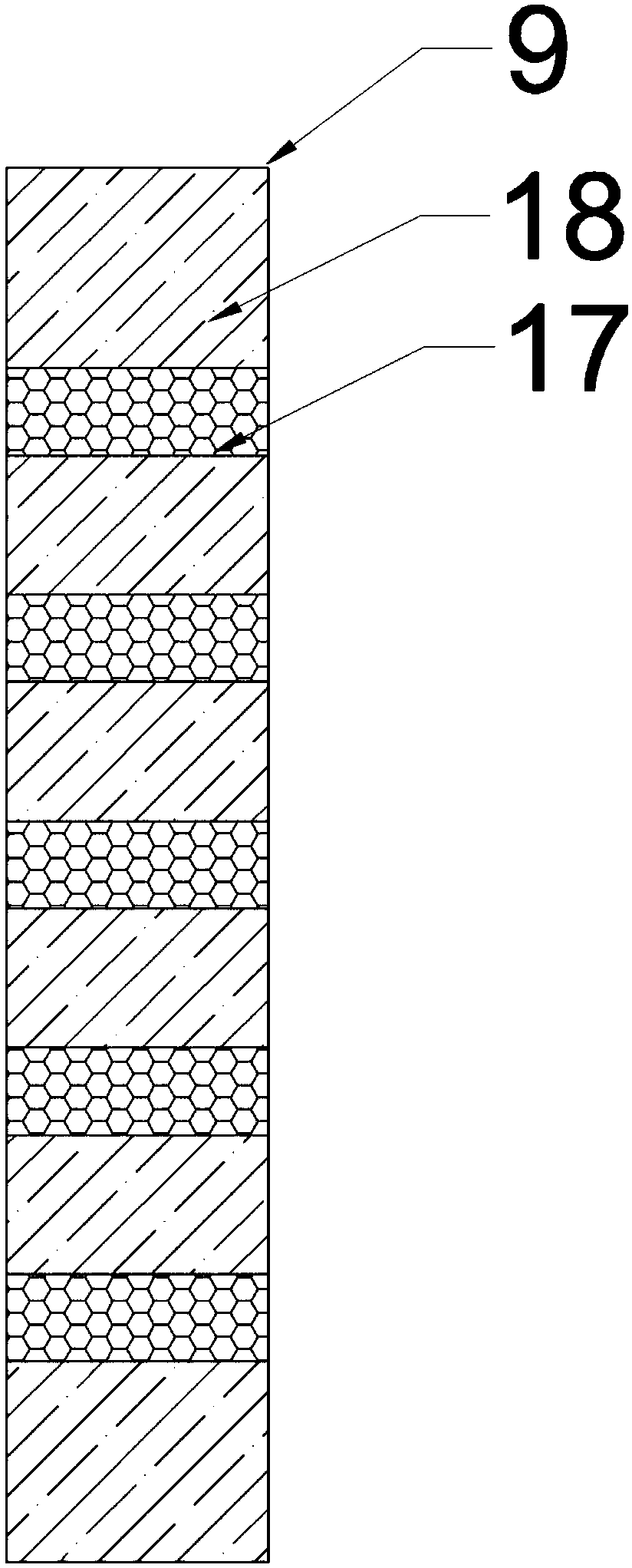

[0038] Such as figure 1 and figure 2 shown, combined with Figure 4 , the integrated iron-based decontamination and resource recycling microbial fuel cell of the present invention comprises an anode chamber A and a cathode chamber B, the cathode chamber B is set inside the anode chamber A, and the cathode chamber B and the anode chamber A are filled with The waste water of power generation; the area around the cathode chamber ring wall 9 of the cathode chamber B is the main reaction zone of the cathode chamber B,

[0039] A cathode 5 is arranged in the cathode chamber B, and a denitrification biofilm is attached to the surface of the cathode 5, and an electric wire 8 is connected to the cathode 5;

[0040] The lower part of the cathode ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com