Non-contact type measuring method and structure for rubber covered roller of rice huller, and rice huller

A non-contact, measuring method technology, applied in grain processing, grain pod removal, grain husking, etc., can solve the problems of husking rate and yield impact, gear speed cannot be adjusted steplessly, and instantaneous speed fluctuation of two rollers, etc. Achieve the effect of preventing the electric field interference of the rubber roller, improving the shelling rate and output, and avoiding instantaneous speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

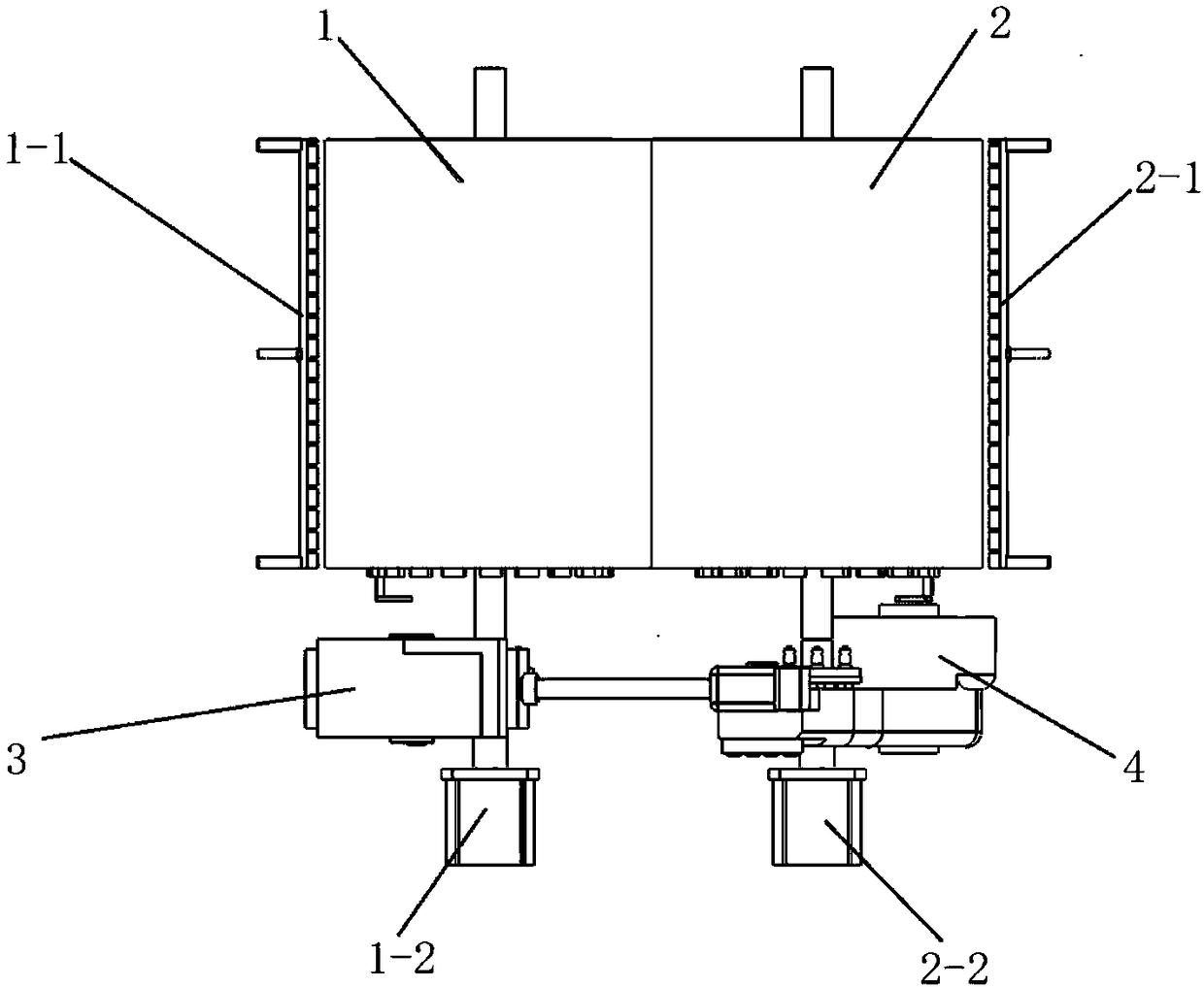

[0040] The non-contact measuring structure of the rubber roller of the huller, including measuring the fixed plate, the moving plate electrode, the air capacitance monitor, the stator electrode, and the PLC controller, such as Figure 1-Figure 4 As shown, in this embodiment, the measuring fixed pole plate includes the fixed roller measuring fixed pole plate 1-1, the moving roller measuring fixed pole plate 2-1, and the moving pole plate electrode includes the fixed roller moving pole plate electrode 1-5-1, Moving roll moving plate electrode 2-5-1, air capacitance monitor includes fixed roll air capacitance monitor 1-3, moving roll air capacitance monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com