Preparation method of three-dimensional woven hair net

A three-dimensional machine and hair weaving technology, which is applied in textiles, fabrics, wigs, etc., can solve the problems of not being able to adapt to the needs of rapid development, low efficiency of hair transplantation, and easy occurrence of defective products, so as to meet the requirements of reducing the proficiency and quality of workers, reducing Quantity, the effect of solving low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

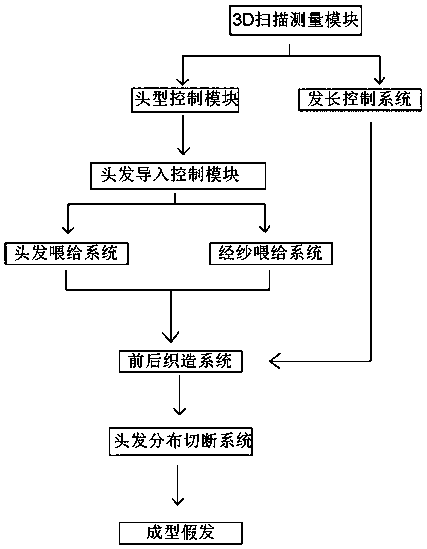

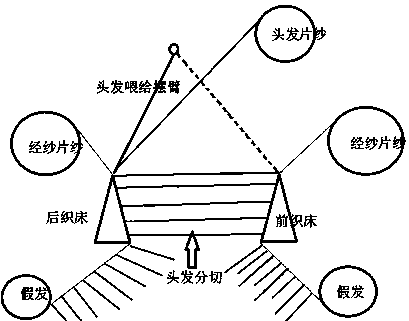

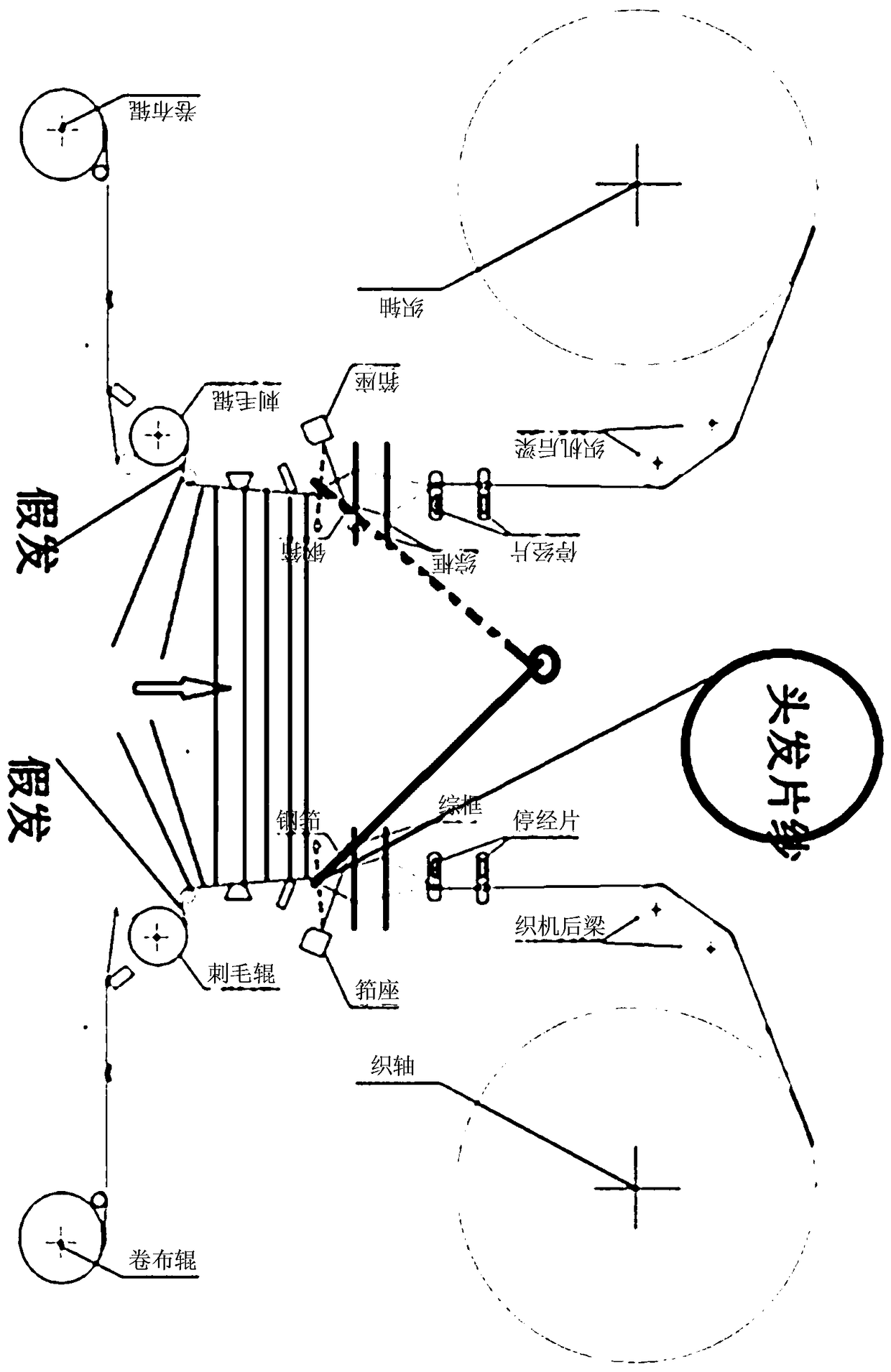

[0026] Embodiment 1: as Figure 1~4 As shown, a preparation method of a three-dimensional woven hair cover, including a 3D scanning measurement module, a head shape control module, a hair length control module, a hair distribution and cutting module, a warp feeding system, a hair feeding system, a hair import control module, Front and rear weaving system, the steps are as follows,

[0027] Step 1: The 3D scanning measurement module scans the customer's head shape, obtains the customer's head shape data, and sends the obtained head shape data to the head shape control module and the hair length control module;

[0028] Step 2: The hair length control module includes a motor, a controller, and a lead screw that controls the distance between the front loom and the rear loom. According to the head shape data, the motor drives the lead screw to rotate under the control of the controller to make the distance between the front and rear looms No less than the head shape data needs to...

Embodiment 2

[0034] Embodiment 2: On the basis of Embodiment 1, the 3D scanning measurement module includes a basic data scanning system and a special parameter input system. When in use, the 3D scanning measurement module scans the customer's head shape to obtain the basic data of the head shape, and the customer fills in the special needs through the special parameter input system into the 3D scanning measurement module, and finally obtains the complete model data of the wig. The complete model data is sent to the head shape control module, and the others are the same as in Embodiment 1.

Embodiment 3

[0035] Embodiment 3: On the basis of Embodiment 1, the head shape control module includes a hair participating in weaving controller and a hair introducing needle control device. During use, the hair participates in the weaving controller to control the hair introduction needle control device, the hair introduction needle control device controls the movement of the hair introduction needle, and then controls the introduction and non-introduction of hair, and weaves to form the head-shaped wig required by the customer. Other embodiment 1 is the same .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com