A kind of superheater and reheater anti-deposition type composite cleaning agent, device and method

A reheater and superheater technology, which is applied in the field of chemical cleaning chemicals, can solve the problems of chemical performance impact, high cleaning costs, and high cost of chemicals, and achieve the effects of low stripping ability, strong cleaning ability, and remarkable synergistic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

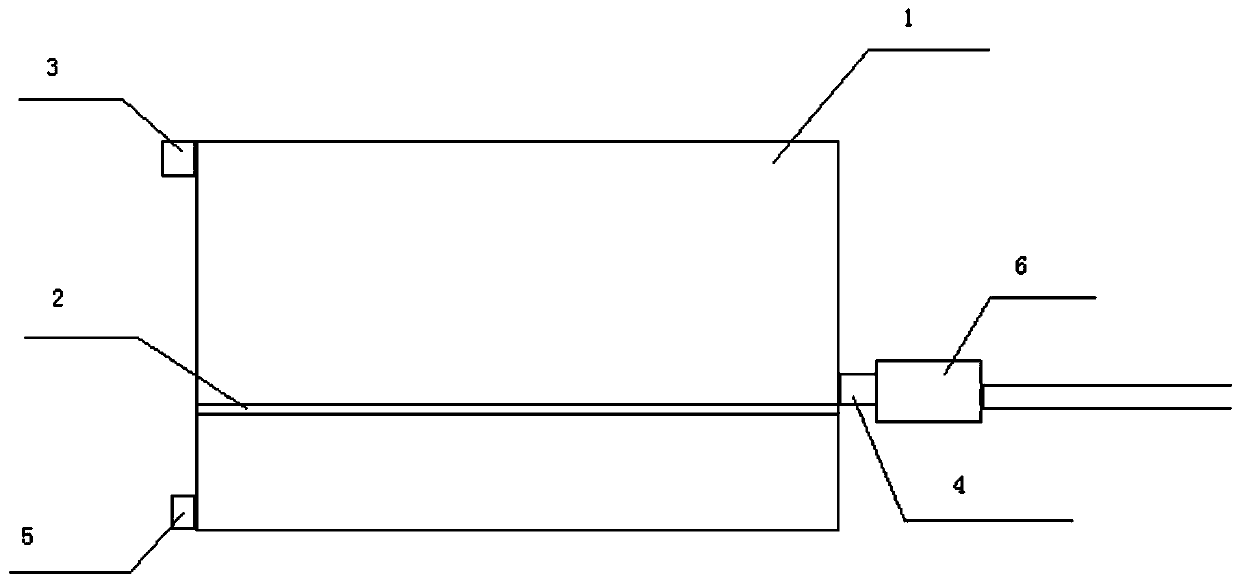

[0049] Choose a cleaning box 1 with a length of 5m, a width of 2.5m, and a height of 3.5m, and set a porous plate 2 in the middle. The thickness of the porous plate 2 is 0.5mm. The porous plate 2 is covered with round holes, and the diameter of the round holes is 4mm. The perforated plate 2 is divided into upper and lower layers, the lower layer is 0.6m high and is used to store a small amount of washed sediment. The suction inlet of the cleaning pump 6 is 0.8m high and inclined upward at 15 degrees.

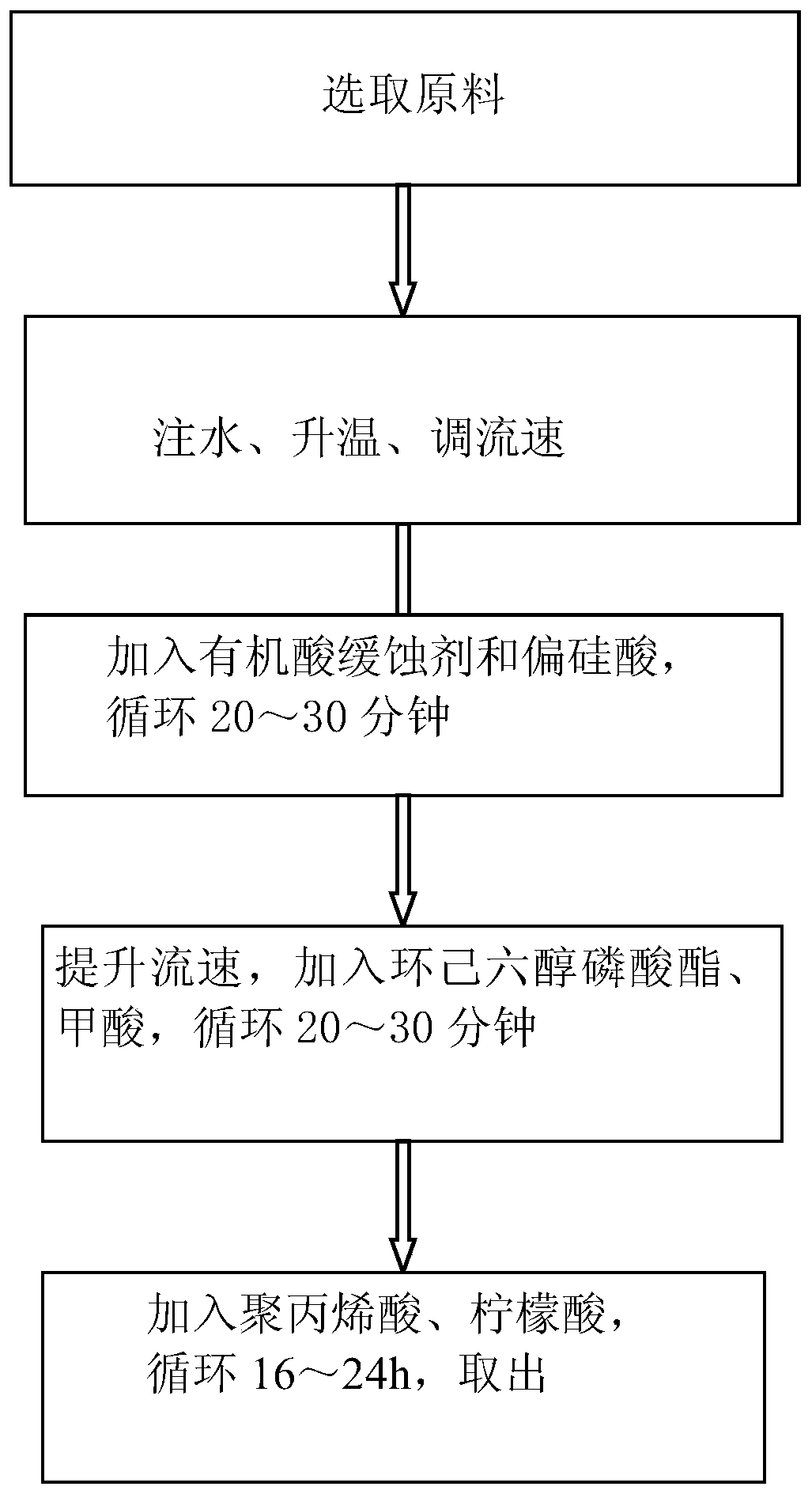

[0050] Open the water inlet 3, fill the cleaning tank 1 with water, put the superheater or reheater in, then raise the water temperature in the cleaning tank 1 to 80°C, and adjust the liquid flow rate in the cleaning tank 1 to 1.5m / s ;

[0051] Close the water inlet 3, add 0.3% organic acid corrosion inhibitor and 0.1% metasilicate in sequence, and circulate for 25 minutes;

[0052] Increase the flow rate in the cleaning tank 1 to 2m / s; add 3% cyclohexyl phosphate and 0.6% form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com