Full-transparence high-strength self-repairing polyurethane elastomer as well as preparation method and application thereof

A polyurethane elastomer, high-strength technology, applied in the field of materials, to achieve the effect of improving strength and realizing physical entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

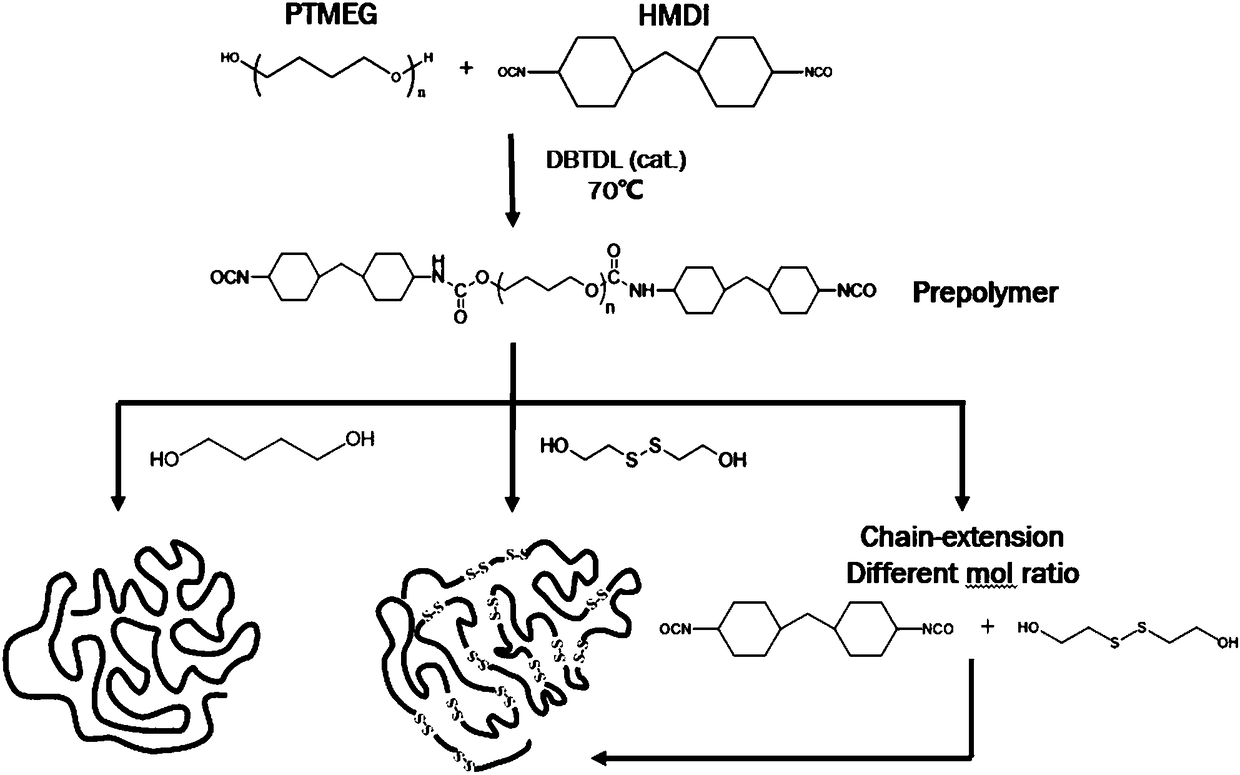

Method used

Image

Examples

Embodiment 1

[0045] 1) Put 17.50 g of polytetramethylene ether glycol (molecular weight: 800) with a concentration of 20 mmol / L in a reaction kettle, heat to melt and stir thoroughly, raise the temperature to 120°C, and keep the vacuum degree of the reaction system at 0.08MPa Above, dehydrate for 2-3 hours; then fill with nitrogen, lower the temperature to 70°C, add 11ml of 4,4-diisocyanate dicyclohexylmethane with a concentration of 42mmol / L and 0.04g of dibutyltin dilaurate, and keep the vacuum degree of the reaction system at 0.08MPa or more, and react for 2-3h under the condition of filling nitrogen gas to generate isocyanate group-terminated polyurethane prepolymer.

[0046] 2) Mix 30ml of N,N-dimethylacetamide and 2.50ml of 2-hydroxyethyl disulfide with a concentration of 20mmol / L, add 10% polystyrene, stir and mix well, and then add to step ( 1) In the obtained isocyanate group-terminated polyurethane prepolymer, the reaction is continued for 2-3 hours to obtain a fully transparent ...

Embodiment 2

[0058] 1) Put 17.50 g of polytetramethylene ether glycol (molecular weight: 1000) with a concentration of 20 mmol in a reaction kettle, heat to melt and stir thoroughly, raise the temperature to 120° C., and keep the vacuum degree of the reaction system above 0.08 MPa, Dehydration for 2-3 hours; then fill with nitrogen, cool down to 70°C, add 16.2ml of 4,4-diisocyanate dicyclohexylmethane and 0.04g of dimethylamine, keep the vacuum of the reaction system above 0.08MPa, and fill with The reaction is carried out for 2-3 hours under the condition of nitrogen to generate a polyurethane prepolymer terminated by isocyanate groups.

[0059] 2) Mix 30ml of N,N-dimethylformamide and 5.2ml of 2-hydroxyethyl disulfide with a concentration of 20mmol, add 10% polyethyleneimine, stir and mix well, then add to step (1 ) In the obtained isocyanate group-terminated polyurethane prepolymer, the reaction is continued for 2-3 hours to obtain a fully transparent and high-strength self-healing poly...

Embodiment 3

[0065] 1) Put 17.5 g of polytetramethylene ether glycol (molecular weight: 3000) with a concentration of 20 mmol in a reaction kettle, heat to melt and stir thoroughly, raise the temperature to 120° C., and keep the vacuum degree of the reaction system above 0.08 MPa, Dehydrate for 2-3 hours; then fill with nitrogen, cool down to 70°C, add 21.5ml of 4,4-diisocyanate dicyclohexylmethane and 0.04g of ferric chloride, keep the vacuum of the reaction system above 0.08MPa, and fill with nitrogen Under the reaction 2-3h, generate isocyanate group-terminated polyurethane prepolymer.

[0066] 2) Get 30ml of chloroform and 7.6ml of 2-hydroxyethyl disulfide with a concentration of 20mmol and mix, add 5% polystyrene and polyethyleneimine (wherein the mass ratio of polystyrene and polyethyleneimine is 1: 1), fully stirred and mixed evenly, and then added to the isocyanate group-terminated polyurethane prepolymer obtained in step (1), and continued to react for 2-3 hours to obtain a fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com