Ceramic powder material for 3D printing

A ceramic powder and 3D printing technology, applied in applications, home appliances, additive processing, etc., can solve problems such as printers not reaching a mature level, material 3D printing obstacles, and expensive materials, and achieve narrow particle size distribution range and stable performance , good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

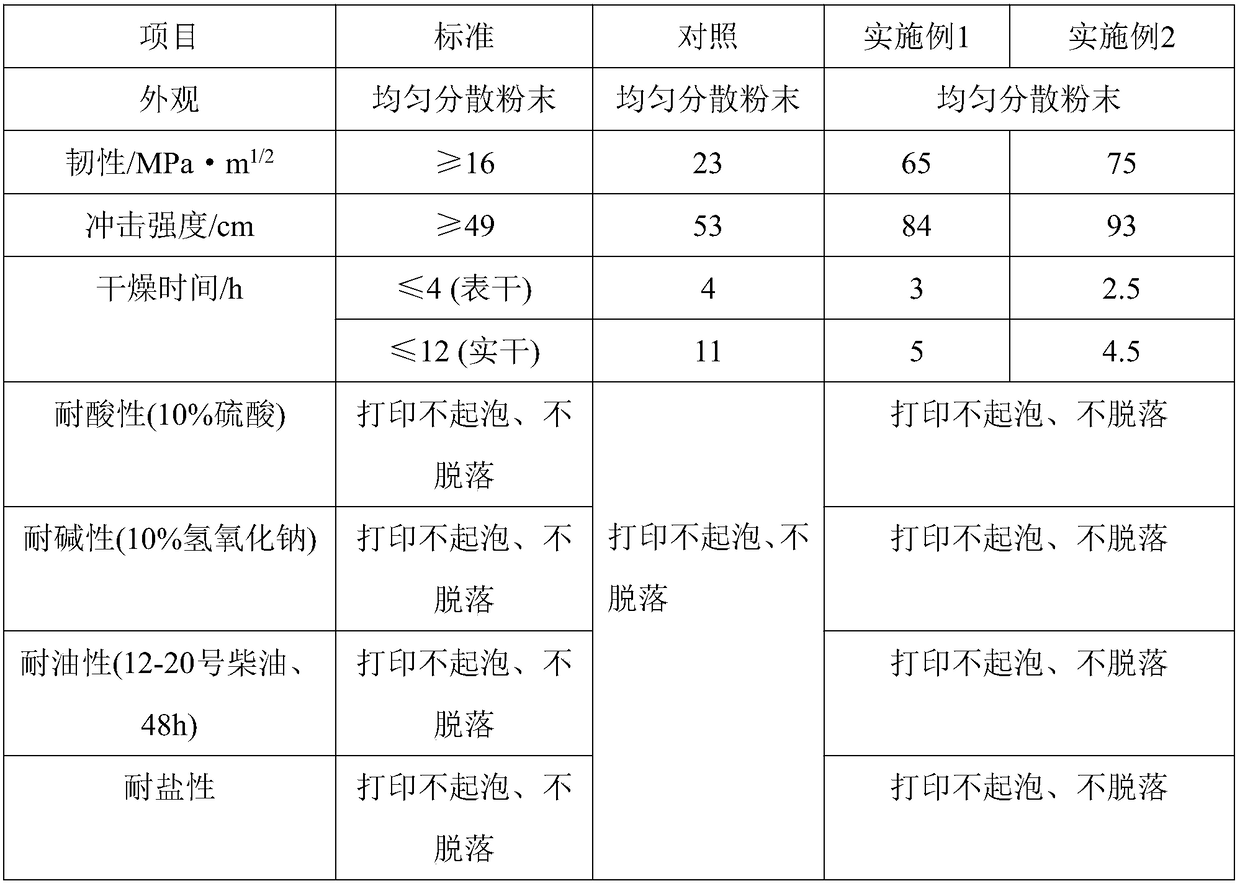

Embodiment 1

[0024] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0025] A ceramic powder material for 3D printing. The ceramic powder material includes the following components: 0.5 parts of Pr solution, 1 part of dispersant, 27 parts of silicone glue, 14 parts of terpene resin, and 20 parts of epoxy vinyl ester resin , 8 parts of graphene powder, 6 parts of organic bismuth antioxidant, 12 parts of sodium stone, 22 parts of Keemun kaolin, 3 parts of zirconium silicate, 4 parts of spodumene, 1.5 parts of potato starch ether, 3 parts of alkali-free glass fiber , 5 parts of bentonite, 1.5 parts of strontium carbonate, 4 parts of modified calcite, and 5 parts of spodumene.

[0026] The dispersant is made of the following raw materials in parts by weight: 5 parts of nano silicon powder, 4 parts of activated carbon, 0.8 part of aluminum powder, 5 parts of tea polyphenols, 3 parts of alkyl glucoside, 2 parts of boric acid, 2.5 ...

Embodiment 2

[0037] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0038] A ceramic powder material for 3D printing. The ceramic powder material includes the following components: 0.7 parts of Pr solution, 4 parts of dispersant, 29 parts of silicone glue, 11 parts of terpene resin, and 20 parts of epoxy vinyl ester resin , 9 parts of graphene powder, 12 parts of organic bismuth antioxidant, 14 parts of sodium stone, 23 parts of Keemun kaolin, 4 parts of zirconium silicate, 3 parts of spodumene, 1 part of potato starch ether, 2 parts of alkali-free glass fiber , 3 parts of bentonite, 1.5 parts of strontium carbonate, 5 parts of modified calcite, and 4 parts of spodumene.

[0039] The dispersant is made of the following raw materials in parts by weight: 5 parts of nano silicon powder, 4 parts of activated carbon, 0.8 part of aluminum powder, 5 parts of tea polyphenols, 3 parts of alkyl glucoside, 2 parts of boric acid, 2.5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com