Method for combining metal with resin

A metal and resin technology, applied in the field of metal and resin compounding, can solve the problems of low yield rate, weak bonding strength, limited application scope, etc., to improve production efficiency, reduce defect rate, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

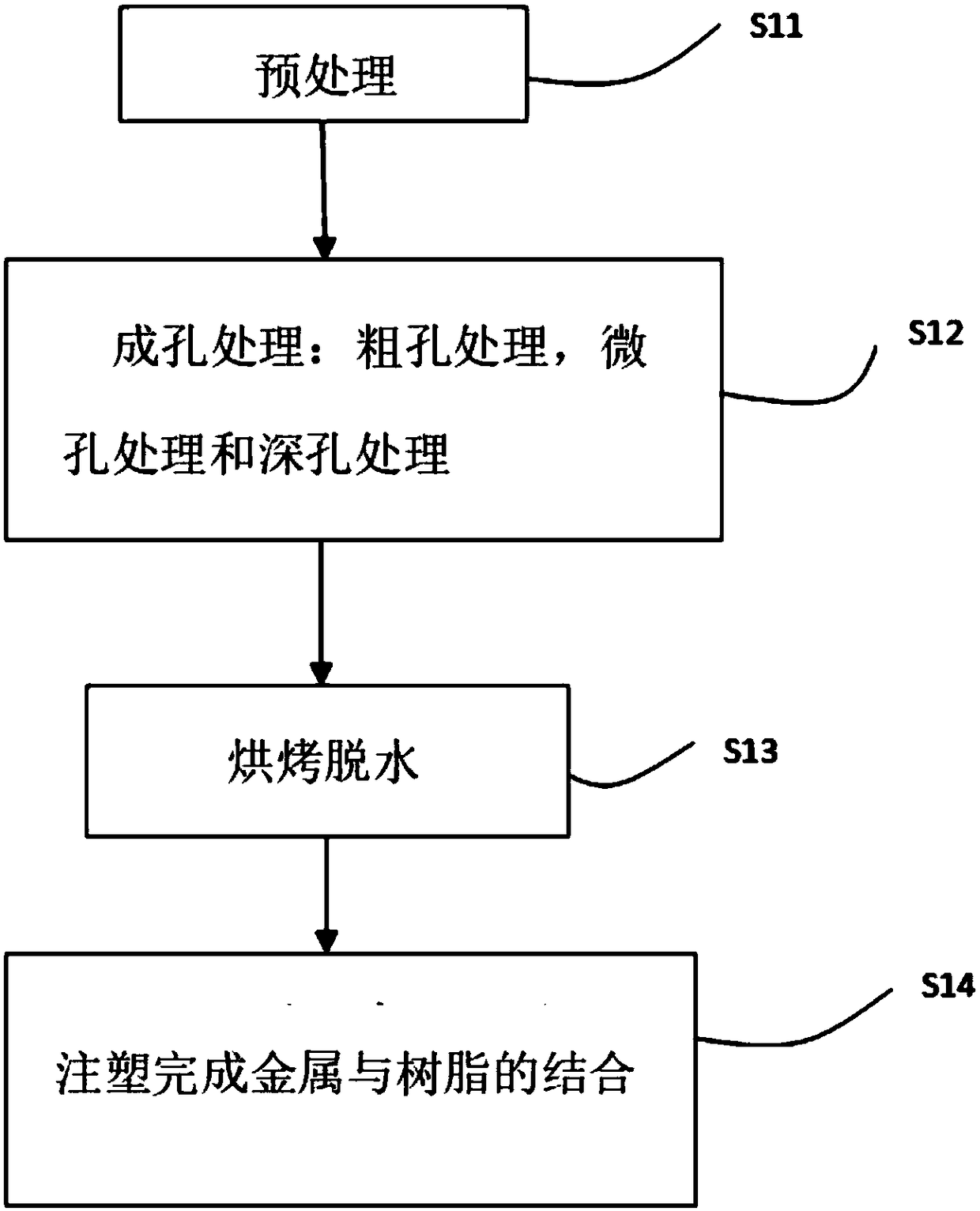

[0044] The concrete steps of this embodiment are:

[0045] – Pretreatment: After degreasing, alkali etching, neutralization, and two water washings on the metal sample, the dirt and natural oxide layer can be clearly shown.

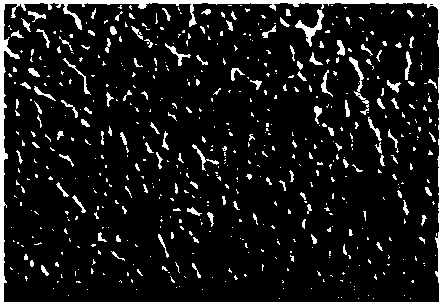

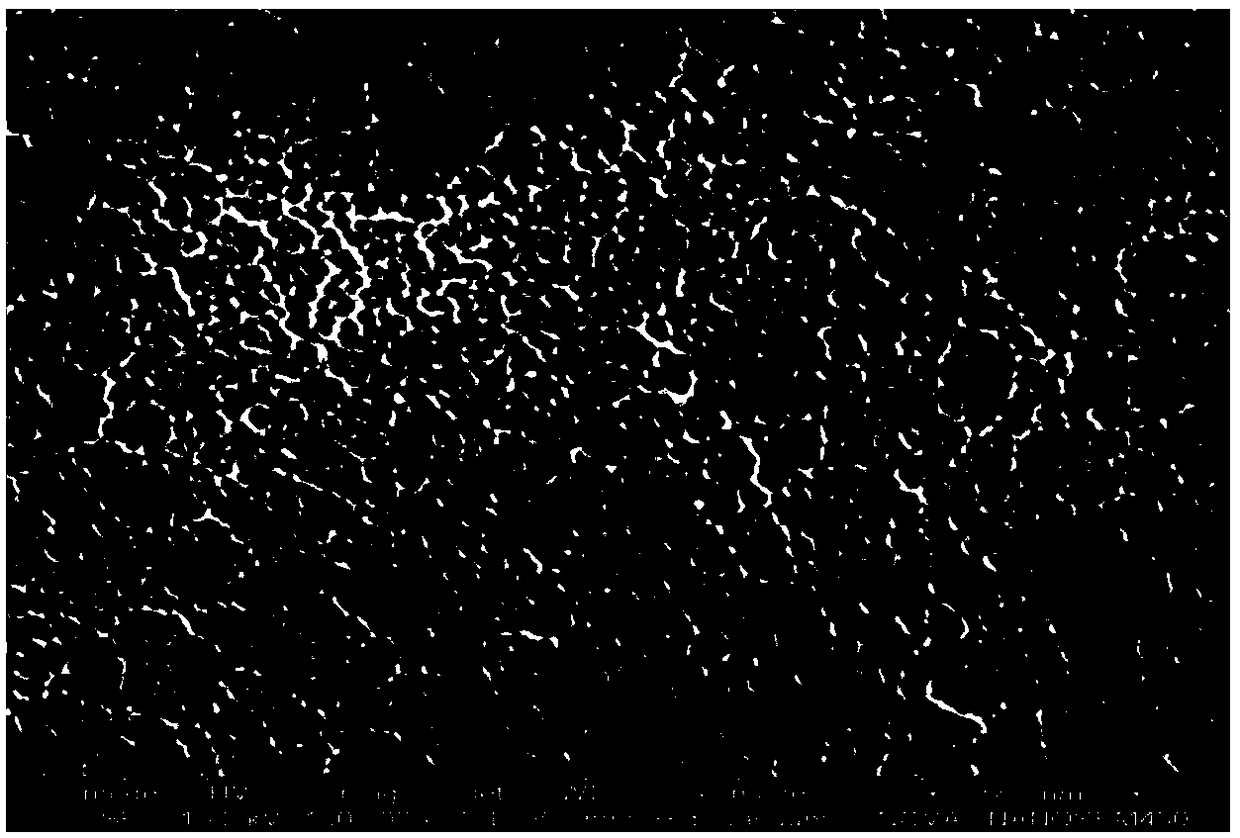

[0046] – Coarse hole treatment, the treatment agent is sodium hydroxide 10-30g / L, sodium nitrate 20-60g / L, sodium chloride 2-10g / L, benzotriazole 1-10g / L, the temperature of the mixed solution is 55- 60°C, ultrasonic power 2.0W, time 50-200S.

[0047] – Microporous treatment, the treatment agent is phosphate 50-150g / L, lactic acid 10-30g / L, acetic acid 5-15g / L, benzotriazole concentration 1-10g / l, temperature 10-20℃, voltage 5 -10V, time 5-20min.

[0048] – Deep hole treatment, the treatment agent is ferric chloride 20-50g / L, oxalic acid 10-30g / L, temperature 40-45℃, time 30-60, pure water washing 2-3 times.

[0049] – Bake and cool

[0050] – Injection molding after cooling for 1 hour, the mold temperature is above 140°C.

[0051] In this embodiment...

Embodiment 2

[0053] This embodiment is roughly the same as the first embodiment, the difference is that after baking and dehydration, it is packaged for 1 hour and then placed for six months before injection molding. The specific steps are:

[0054] – Pretreatment: After degreasing, alkali etching, neutralization, and two water washings on the metal sample, the dirt and natural oxide layer can be clearly shown.

[0055] – Coarse hole treatment, the treatment agent is sodium hydroxide 10-30g / L, sodium nitrate 20-60g / L, sodium chloride 2-10g / L, benzotriazole 1-10g / L, the temperature of the mixed solution is 55- 60°C, ultrasonic power 2.0W, time 50-200S.

[0056] – Microporous treatment, the treatment agent is phosphate 50-150g / L, lactic acid 10-30g / L, acetic acid 5-15g / L, benzotriazole concentration 1-10g / l, temperature 10-20℃, voltage 5 -10V, time 5-20min.

[0057] – Deep hole treatment, the treatment agent is ferric chloride 20-50g / L, oxalic acid 10-30g / L, temperature 40-45℃, time 30-60,...

Embodiment 3

[0062] This embodiment is roughly the same as the previous embodiment, the difference is that injection molding is performed within 1 hour after baking and dehydration, followed by mechanical processing and surface treatment. The specific steps are:

[0063] – Pretreatment: After degreasing, alkali etching, neutralization, and two water washings on the metal sample, the dirt and natural oxide layer can be clearly shown.

[0064] – Coarse hole treatment, the treatment agent is sodium hydroxide 10-30g / L, sodium nitrate 20-60g / L, sodium chloride 2-10g / L, benzotriazole 1-10g / L, the temperature of the mixed solution is 55- 60°C, ultrasonic power 2.0W, time 50-200S.

[0065] – Microporous treatment, the treatment agent is phosphate 50-150g / L, lactic acid 10-30g / L, acetic acid 5-15g / L, benzotriazole concentration 1-10g / l, temperature 10-20℃, voltage 5 -10V, time 5-20min.

[0066] – Deep hole treatment, the treatment agent is ferric chloride 20-50g / L, oxalic acid 10-30g / L, temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com