Automatically-adjusted vortex mixing and anti-blocking ammonia spraying grille apparatus and application method thereof

A self-adjusting, ammonia-injection grid technology, applied in separation methods, chemical instruments and methods, gas treatment, etc. Different air flow rates and other issues, to achieve low equipment and operation and maintenance costs, avoid severe uneven ammonia injection, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0022] Example.

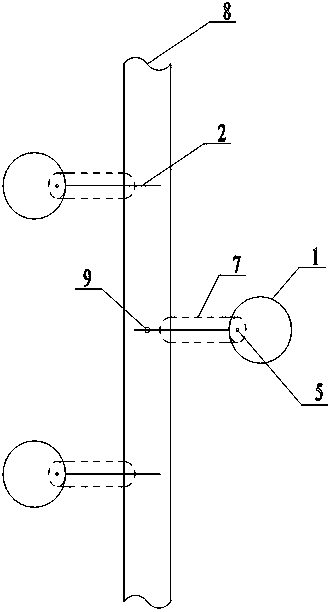

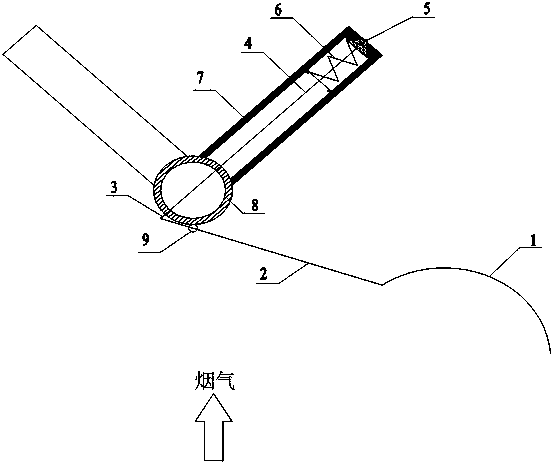

[0023] see Figure 1 to Figure 2 , in this embodiment, the self-adjusting vortex-mixing and anti-clogging ammonia injection grid device and related equipment are arranged at the entrance of the SCR denitrification system and the flue before the denitrification catalyst, and the flue gas passes through the auto-adjusting vortex-mixing and anti-clogging spraying system in turn. The ammonia grid device, related deflectors and rectification grids, then enter the denitrification reactor. The self-adjusting vortex-mixing and anti-blocking ammonia injection grille device includes flue gas velocity tracking device 1, lever 2, hinged part 3, connecting rod 4, nozzle opening adjustment valve 5, elastic part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com