Perovskite film and preparation method thereof and application of perovskite film in photoelectric devices

A technology of perovskite and perovskite materials, which can be used in electric solid devices, photovoltaic power generation, electrical components, etc., and can solve problems such as loss and migration of organic ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

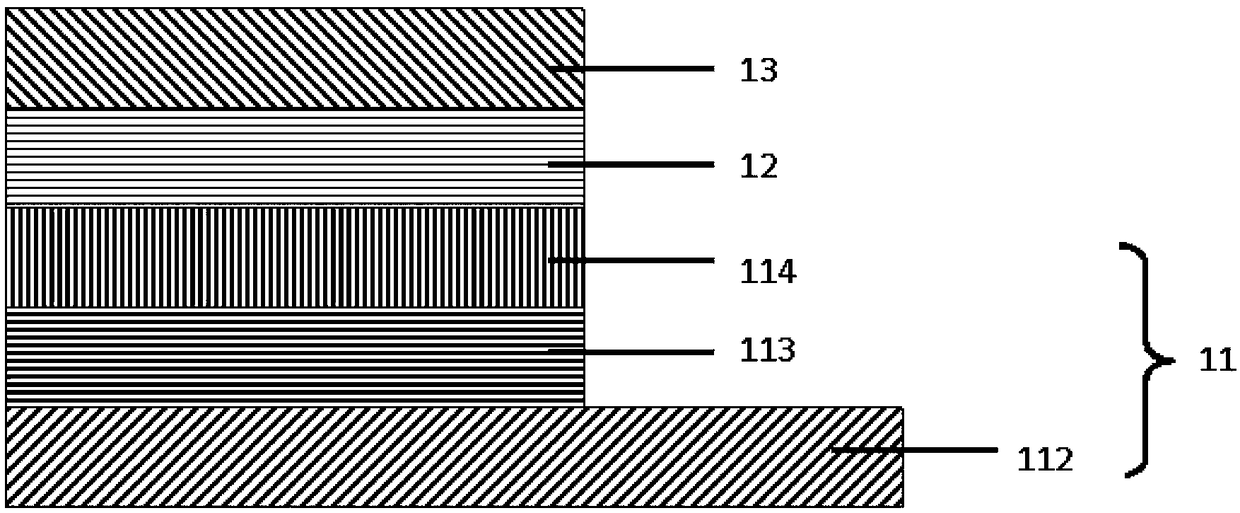

[0064] The embodiment of the preparation method of perovskite film of the present invention comprises the following steps:

[0065] 1. Combine AX and PbX 2 Dissolve in the precursor solvent according to a certain stoichiometric ratio (the precursor solvent is a polar solvent with a high boiling point that can dissolve the perovskite material, such as DMF, DMSO and γ-butyrolactone, etc. or the above two and above mixed solvents) to form a solution with a mass concentration of 25% to 40%. Heat to 70 °C until the solid is completely dissolved, and stir overnight to form a transparent and uniform perovskite precursor solution.

[0066] 2. Take the above precursor solution and drop it on the substrate. The substrate can be an indium tin oxide substrate (ITO / SnO) coated with tin oxide 2 ), dense titanium dioxide (c-TiO 2) of fluorine-doped tin oxide (FTO) glass substrates (FTO / c-TiO 2 ) or FTO / c-TiO coated with porous titania 2 Substrate (FTO / c-TiO 2 / m-TiO 2 ). Within a ce...

Embodiment 1

[0072] The preparation method described in this embodiment comprises the following steps:

[0073] 1. Change CH 3 NH 3 I, NH 2 CHNH 3 I and PbI 2 According to the stoichiometric ratio of 0.15:0.85:1.025, it was dissolved in anhydrous DMF and DMSO mixed solution (600mg / 78mg) to form a solution with a mass concentration of 40%. Heat to 70 °C until the solid is completely dissolved, and stir overnight to form a transparent and uniform perovskite precursor solution.

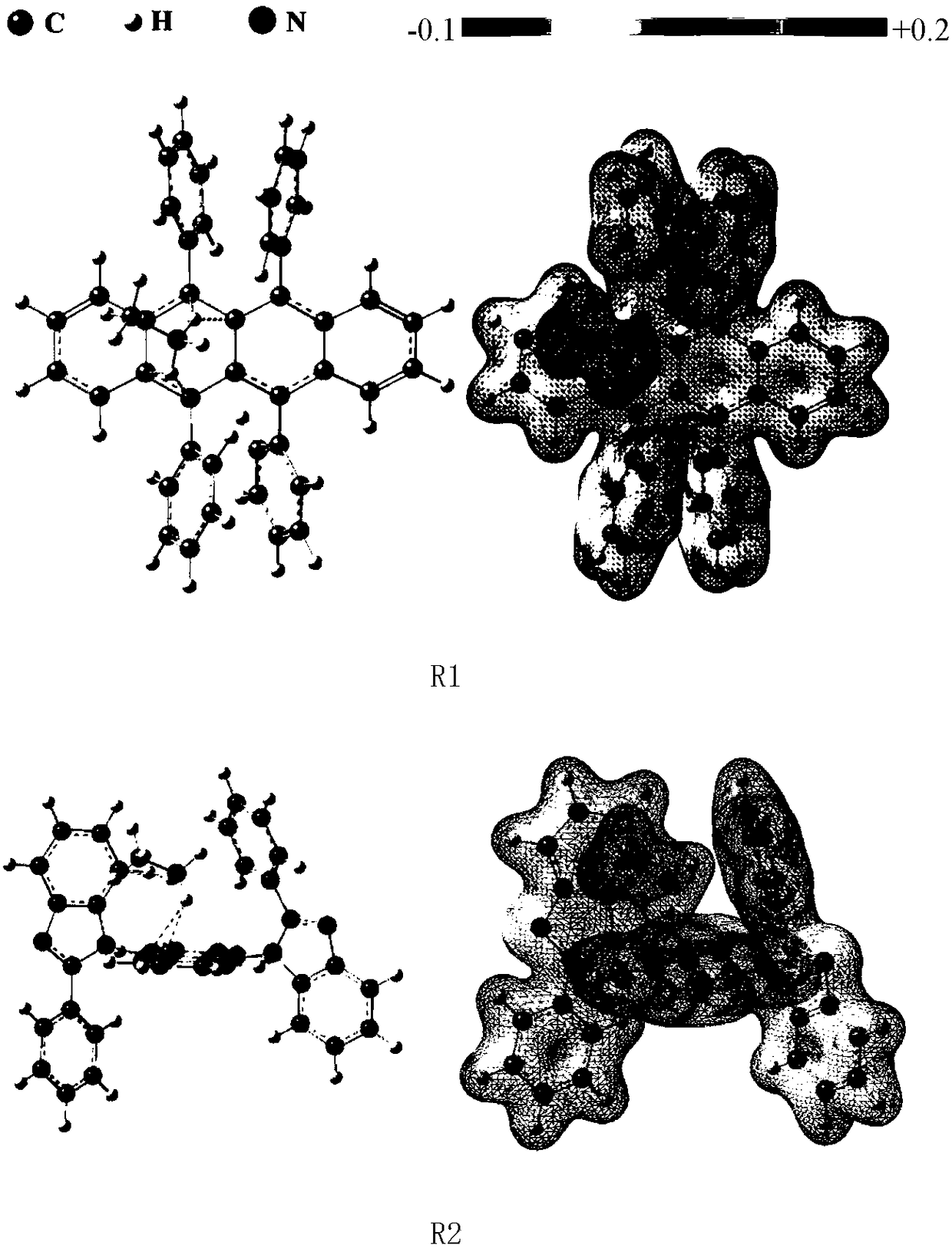

[0074] 2. Take 100uL of the above precursor solution and drop it on a 2cm×2cm ITO / SnO 2 The substrate was spin-coated at 4000 rpm for a total time of 30 seconds. 15 seconds before the end of the spin coating, 500 uL of the chlorobenzene solution containing compound R1 was quickly dropped. After the spin coating, the substrate was dried on a hot plate at 130° C. for 15 minutes to remove residual solvent.

Embodiment 2

[0079] The steps are as in Example 1, except that the anti-solvent is changed to a solution containing compound R2, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com