Controllable and perpendicular bismuth selenide nanosheet thin film and preparation method thereof

A technology of nanosheets and thin films, applied in the fields of photodetection and electronic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

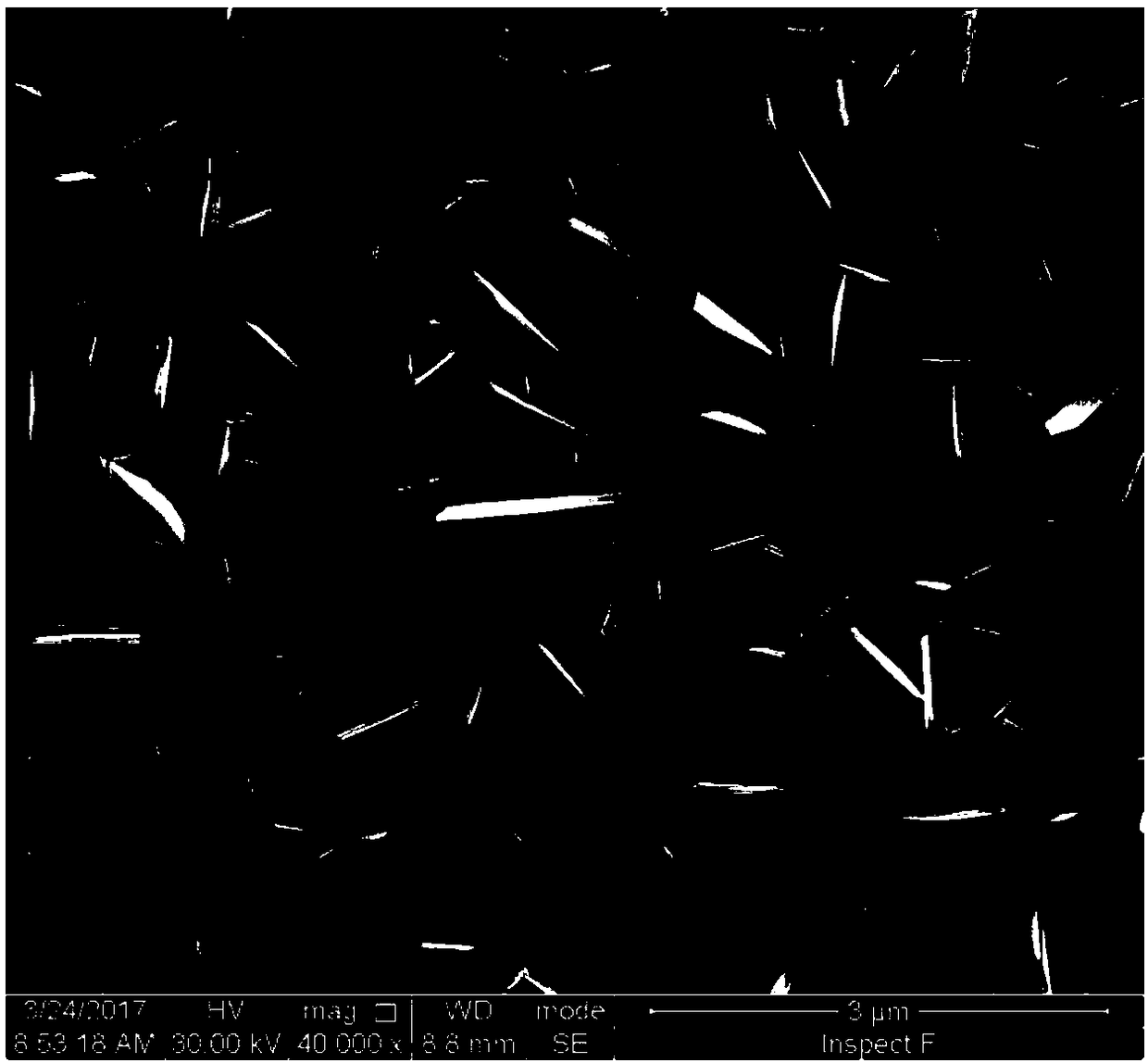

[0041] Preparation of Bi by chemical vapor deposition 2 Se 3 The thin film adopts a P-type silicon substrate as the substrate, and the substrate is cleaned by ultrasound for 5 minutes in ethanol and acetone, and soaked in hydrofluoric acid solution (concentration is 15%) for 1 minute to remove the SiO on the surface. 2 natural oxide layer. The raw material is Bi 2 Se 3 The powder, with a purity of 99.99%, is placed 2 cm upstream from the center of the furnace tube. Before heating, the vacuum in the furnace tube is 0.2Pa, the distance between the substrate and the center of the furnace is 14.5 cm, the total gas flow rate is 50 sccm, the working gas is argon and hydrogen (ratio 4:1), the working pressure is 50 Pa, and the furnace center temperature is 520 °C. Time 3 minutes, Bi 2 Se 3 Thin film scanning electron microscope pictures such as figure 1 shown. Bi 2 Se 3 The current-voltage curves of the PN junction material formed by the thin film and the silicon substrate ...

Embodiment 2

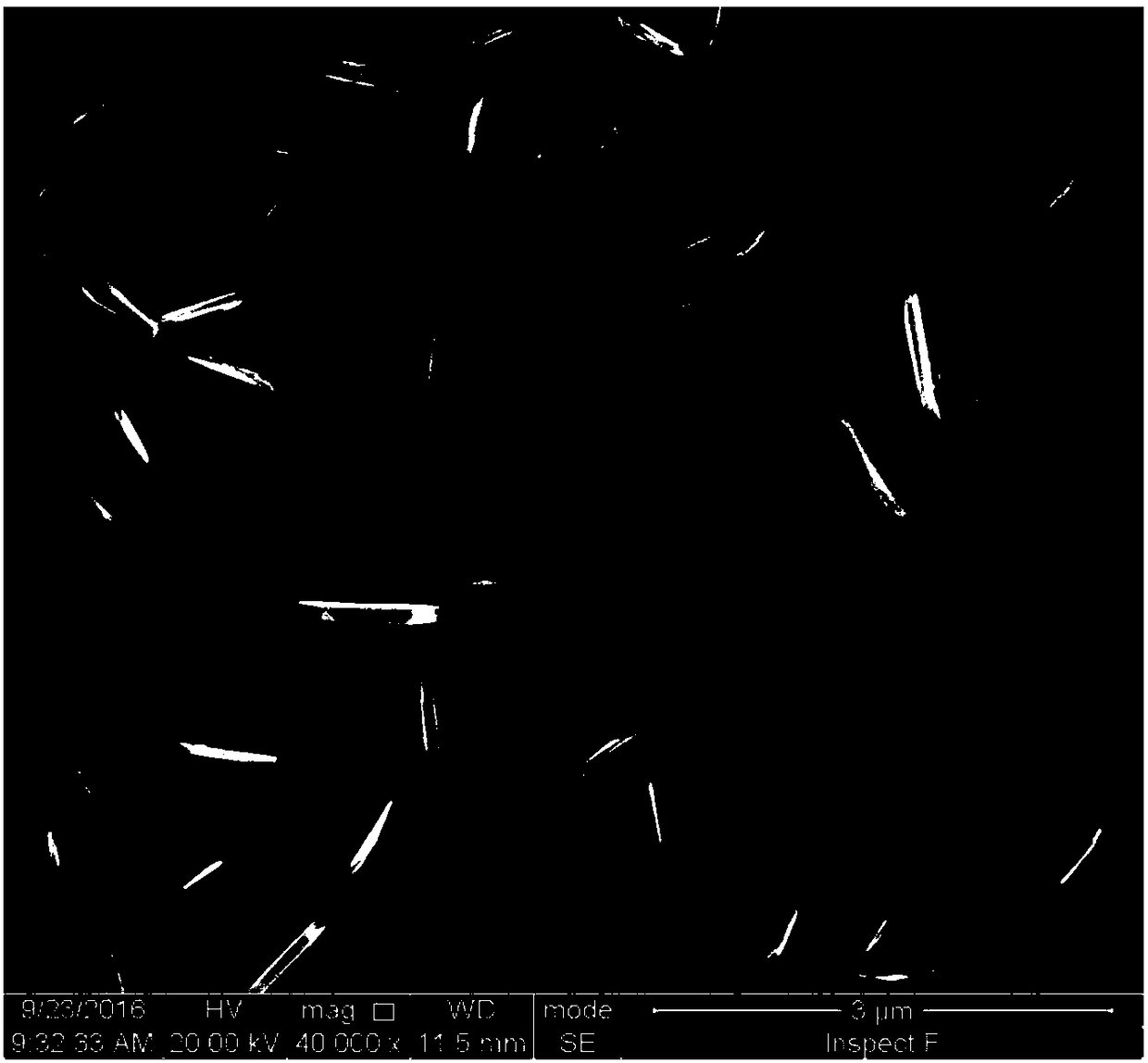

[0043] Preparation of Bi by chemical vapor deposition 2 Se 3 The thin film adopts a P-type silicon substrate as the substrate, and the substrate is cleaned by ultrasound for 5 minutes in ethanol and acetone, and soaked in hydrofluoric acid solution (concentration is 15%) for 1 minute to remove the SiO on the surface. 2 natural oxide layer. The raw material is Bi 2 Se 3 The powder, with a purity of 99.99%, is placed 2 cm upstream from the center of the furnace tube. The distance between the substrate and the center of the furnace is 14.5 cm, the total gas flow rate is 50 sccm, the working gas is argon and hydrogen (ratio 4:1), the working pressure is 50 Pa, the temperature in the center of the furnace is 520 ° C, the working time is 4 minutes, Bi 2 Se 3 Thin film scanning electron microscope pictures such as figure 2 shown. Bi 2 Se 3 The optical test result of the PN junction material formed by the thin film and the silicon substrate is similar to that of Example 3. ...

Embodiment 3

[0045] Preparation of Bi by chemical vapor deposition 2 Se 3 The thin film adopts a P-type silicon substrate as the substrate, and the substrate is cleaned by ultrasound for 5 minutes in ethanol and acetone, and soaked in hydrofluoric acid solution (concentration is 15%) for 1 minute to remove the SiO on the surface. 2 natural oxide layer. The raw material is Bi 2 Se 3 The powder, with a purity of 99.99%, is placed 2 cm upstream from the center of the furnace tube. The distance between the substrate and the center of the furnace is 14.5 cm, the total gas flow rate is 50 sccm, the working gas is argon and hydrogen (ratio 4:1), the working pressure is 50 Pa, the temperature in the center of the furnace is 520 ° C, the working time is 5 minutes, Bi 2 Se 3 Thin film scanning electron microscope pictures such as image 3 As shown, the X-ray diffraction pattern is as Figure 16 As shown, Bi 2 Se 3 The current-voltage curves of the PN junction material formed by the thin fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com