Laser engraving machine, control system and control method

A technology of laser engraving machine and control method, applied in general control system, control/regulation system, computer control and other directions, can solve the problem of failure to consider the redundancy and correlation of feature subsets, less unsupervised methods, and diverse solution sets poor sexual performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified, and are described in detail below with accompanying drawings.

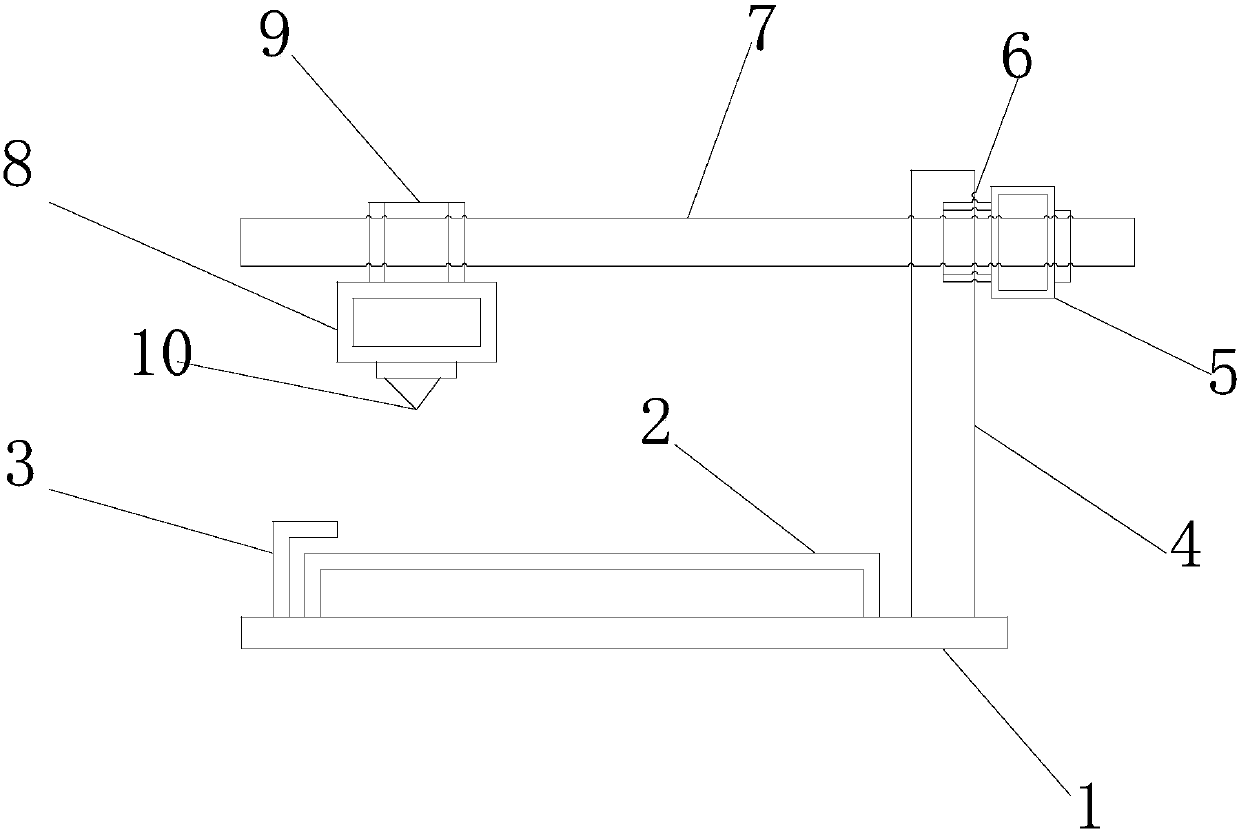

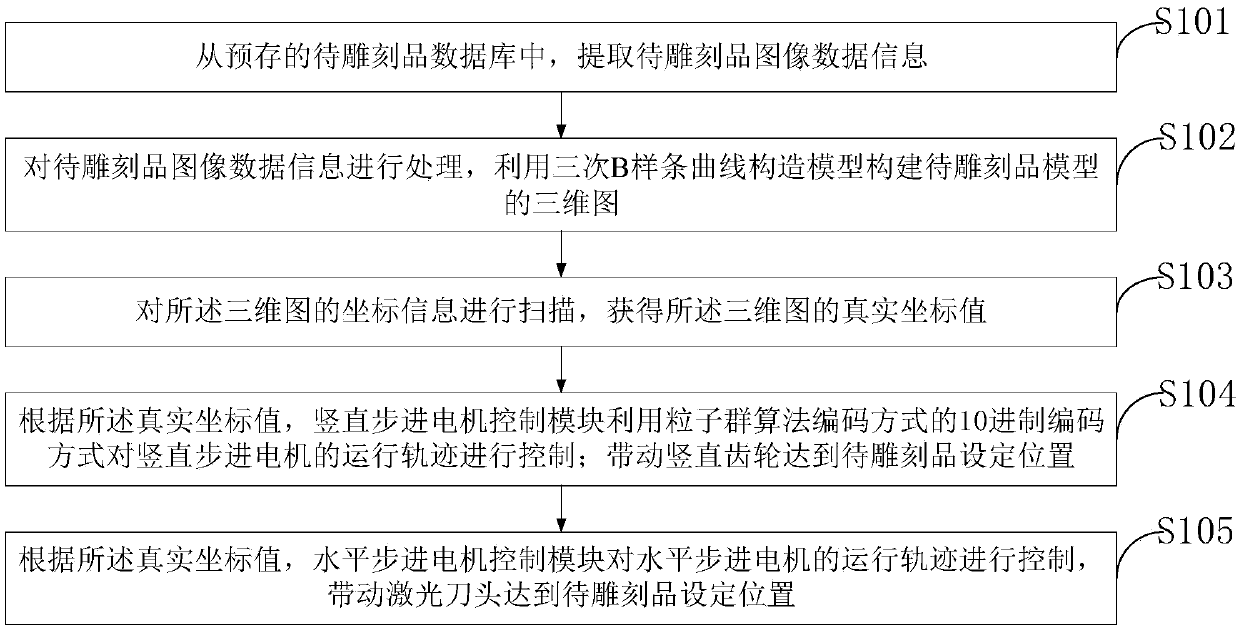

[0111] Such as Figure 1-Figure 2 As shown, the laser engraving machine provided by the embodiment of the present invention is provided with a base 1, a stage 2, a fixing frame 3, a vertical guide 4, a vertical stepping motor 5, a vertical gear 6, a horizontal guide 7, and a horizontal step. Into the motor 8, the horizontal gear 9, the laser cutter head 10.

[0112] The stage 2 is located above the base 1 and fixed on the base 1 by bolts. The fixing frame 3 is located on the left side of the base 1 and fixed on the base 1 by bolts. The vertical rail 4 is located on the right side of the base 1 and fixed on the base by bolts. On 1, the horizontal guide rail 7 is located on the vertical guide rail 3, the vertical stepping motor 5 is located on the horizontal guide rail 7, and is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com