Auxiliary device for assembling wire harness and method for producing wire harness

An auxiliary device and wiring technology, applied in the manufacture of wire harnesses, cable/conductor manufacturing, electrical components, etc., can solve the problems of multi-working time, waste, and easy winding of wires, terminals and plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

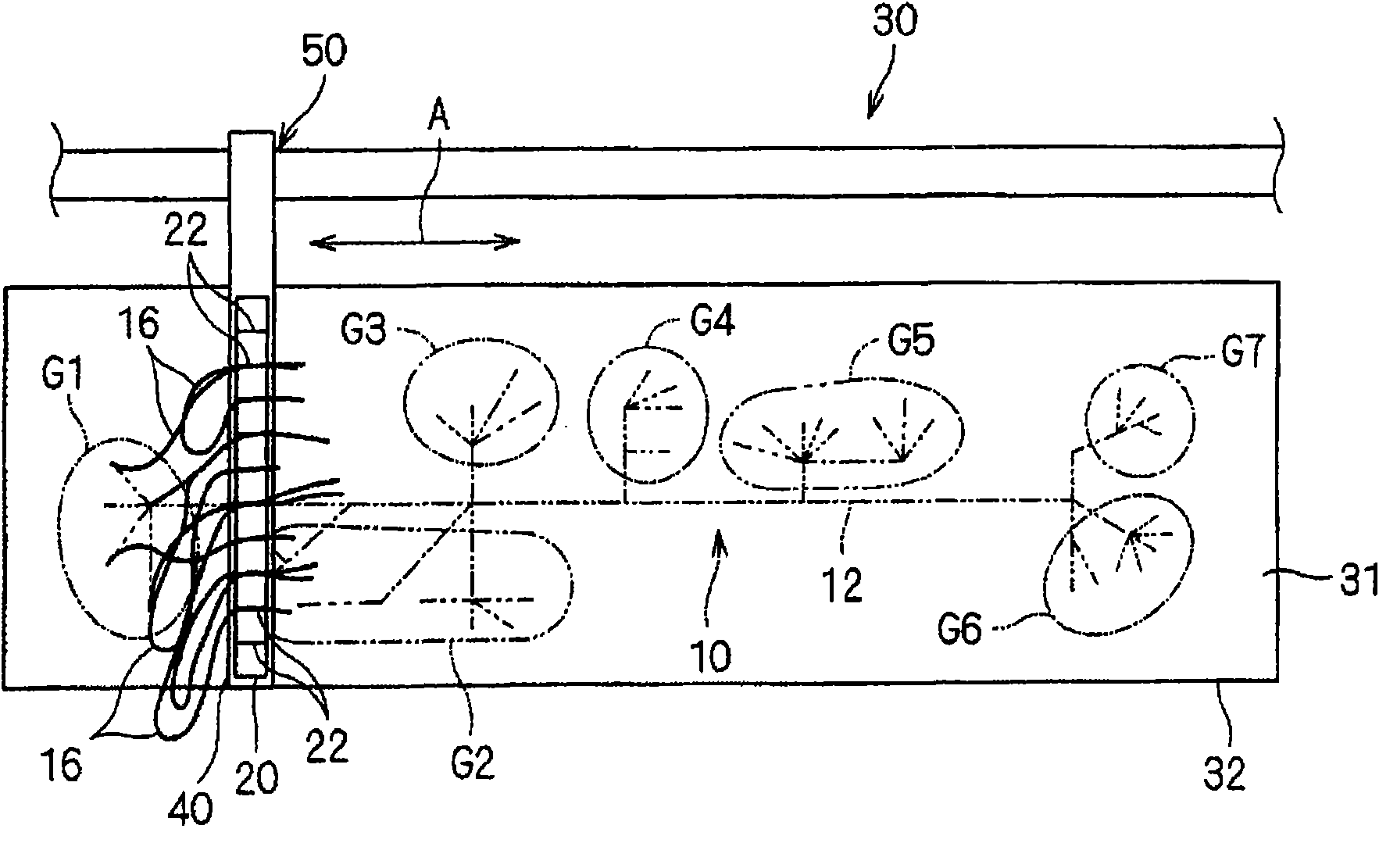

[0040] Hereinafter, the auxiliary device for wiring harness assembly and the manufacturing method of the wiring harness which concerns on embodiment are demonstrated.

[0041]Here, after describing the basic configuration of the auxiliary device for wiring harness assembly and the manufacturing method of the wiring harness, two more specific examples of the auxiliary device for wiring harness assembly will be described.

[0042] 1. Basic configuration of wiring harness assembly auxiliary device and wiring harness manufacturing method

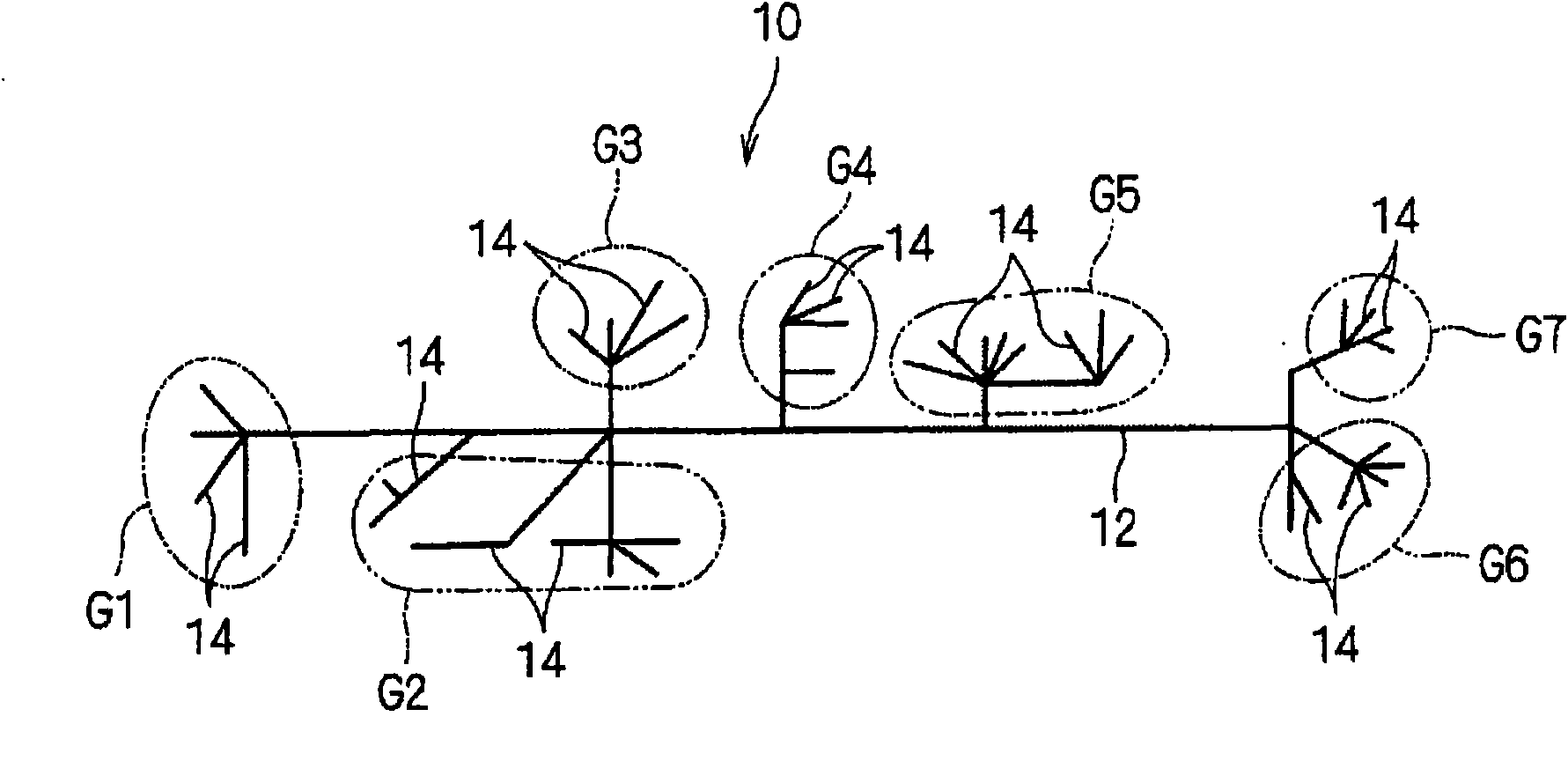

[0043] First, a wiring harness to be manufactured will be described. figure 1 It is a figure which shows the wiring form example of a wiring harness.

[0044] The wiring harness 10 is used as a wiring material of a vehicle, and is assembled in a predetermined wiring form obtained by two-dimensionally developing a three-dimensional wiring form of a vehicle. The wiring harness 10 is configured by concentrating and branching a plurality of electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com