Novel carbon fiber microelectrode and preparation method thereof

A carbon fiber and micro-electrode technology, applied in the field of new carbon fiber micro-electrodes and their preparation, can solve the problems of harsh high-temperature curing conditions, easy contamination of analysis samples, low detection sensitivity, etc., and achieves good electrochemical performance, wide application prospects, raw materials Inexpensive and accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

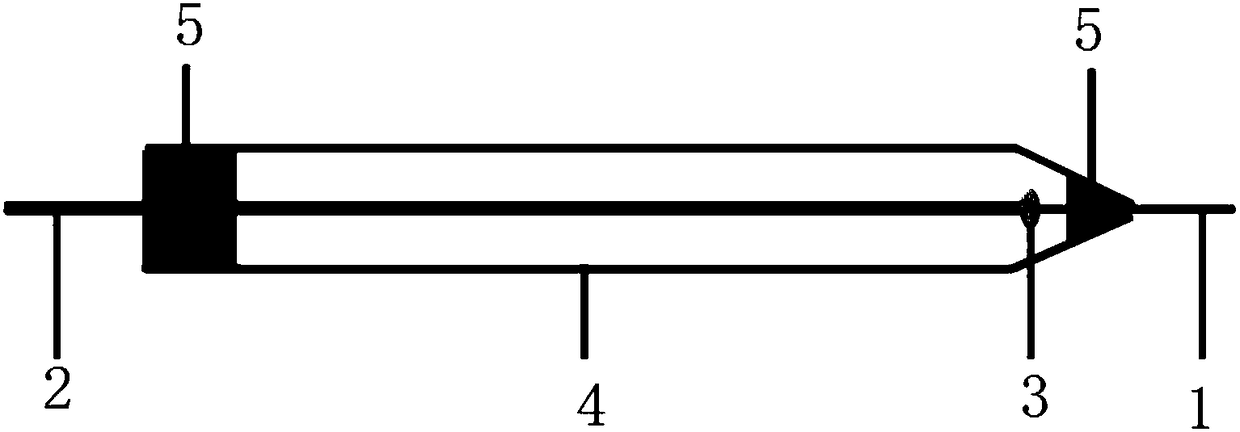

[0034] Reference numerals in the accompanying drawings include:

[0035] Carbon fiber 1, copper wire 2, conductive silver paint 3, glass capillary 4, short wax column 5.

[0036] like figure 1 The new carbon fiber microelectrode shown includes carbon fiber 1 and copper wire 2. Carbon fiber 1 has a length of about 1.5 cm and a diameter of 7 μm, and copper wire 2 has a length of about 5 cm and a diameter of 40 μm. The left end of the carbon fiber wire 1 and the right end of the copper wire 2 are connected and cured by the conductive silver paint 3, and the resistance of the conductive silver paint 3 is <0.02ohm / sq. The cured carbon fiber filament 1-copper filament 2 is covered with a glass capillary 4 whose right end is a pointed end. The inner diameter of the glass capillary 4 is 0.76mm, the outer diameter is 1.0mm, and the tip of the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com