Dielectric elastomer active vibration isolation air spring

A dielectric elastomer, air spring technology, applied in springs, gas shock absorbers, springs/shock absorbers, etc., can solve the problems of high noise, small size, and bulky equipment, and achieve light weight, small size, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

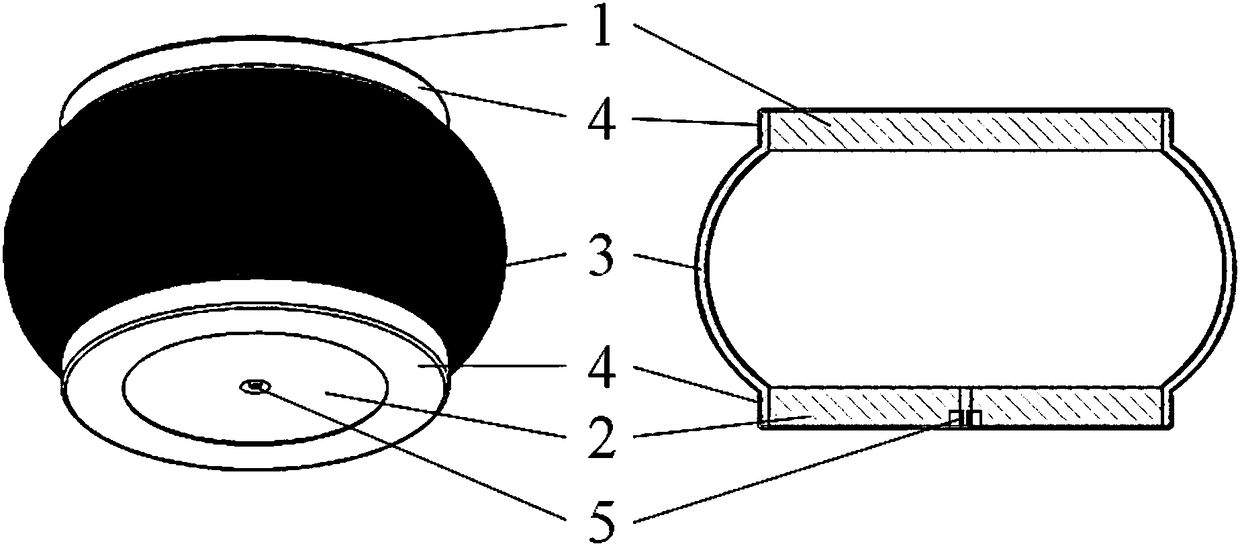

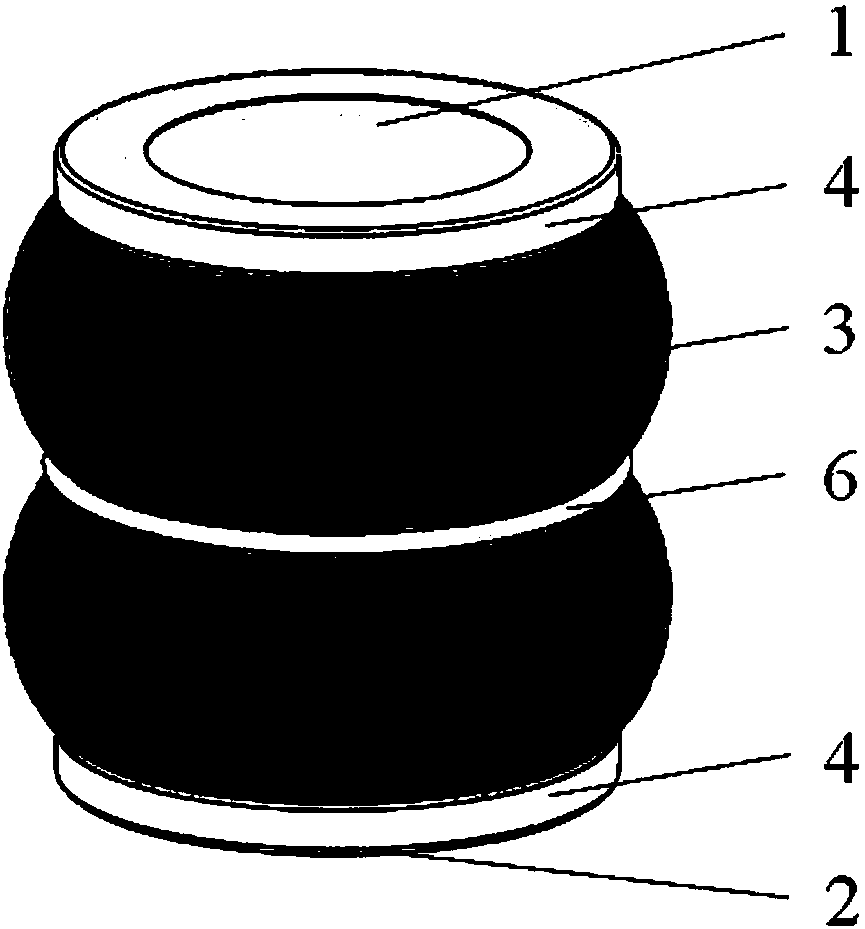

[0015] Such as Figure 1~2 As shown, this embodiment includes: a dielectric elastomer airbag 3 with upper and lower end caps 1, 2, wherein: the dielectric elastomer airbag 3 is hollow inside and forms an airbag structure.

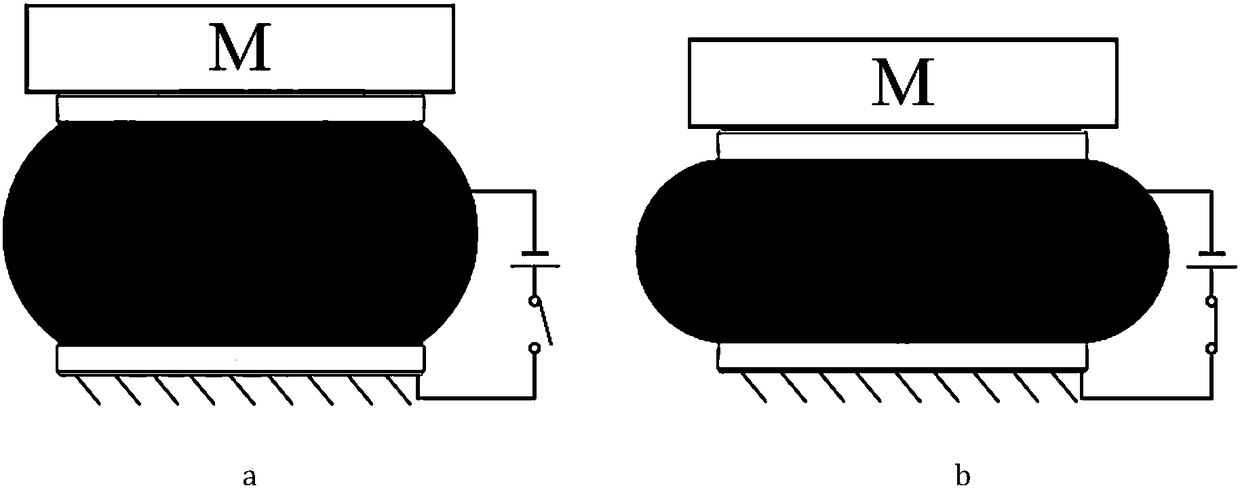

[0016] The dielectric elastomer airbag 3 is composed of a silicone film or a rubber film coated with flexible electrodes on both sides, and the flexible electrode material adopts but is not limited to graphite carbon fat, single-walled carbon nanotube solution or ion gel; When a voltage is applied to the electroelastomer airbag 3, the induced Maxwell stress will cause the area of the airbag to expand and reduce its thickness. Different descending displacements are generated; when the voltage is removed, the air spring will quickly recover, and the load M will be lifted to the original position; thus, active vibration isolation is realized by controlling the applied voltage.

[0017] The center of the upper end cover 1 or the lower end cover 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com