Speed loss and variable pitch mixed control method for permanent magnetic direct drive wind generating set

A wind turbine, permanent magnet direct drive technology, applied in the control of wind turbines, engine control, wind turbines, etc., can solve the problems of high failure rate of wind turbines, difficult to accurately calculate the stall effect, etc., and achieve stable output results. , The effect of stable power output and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

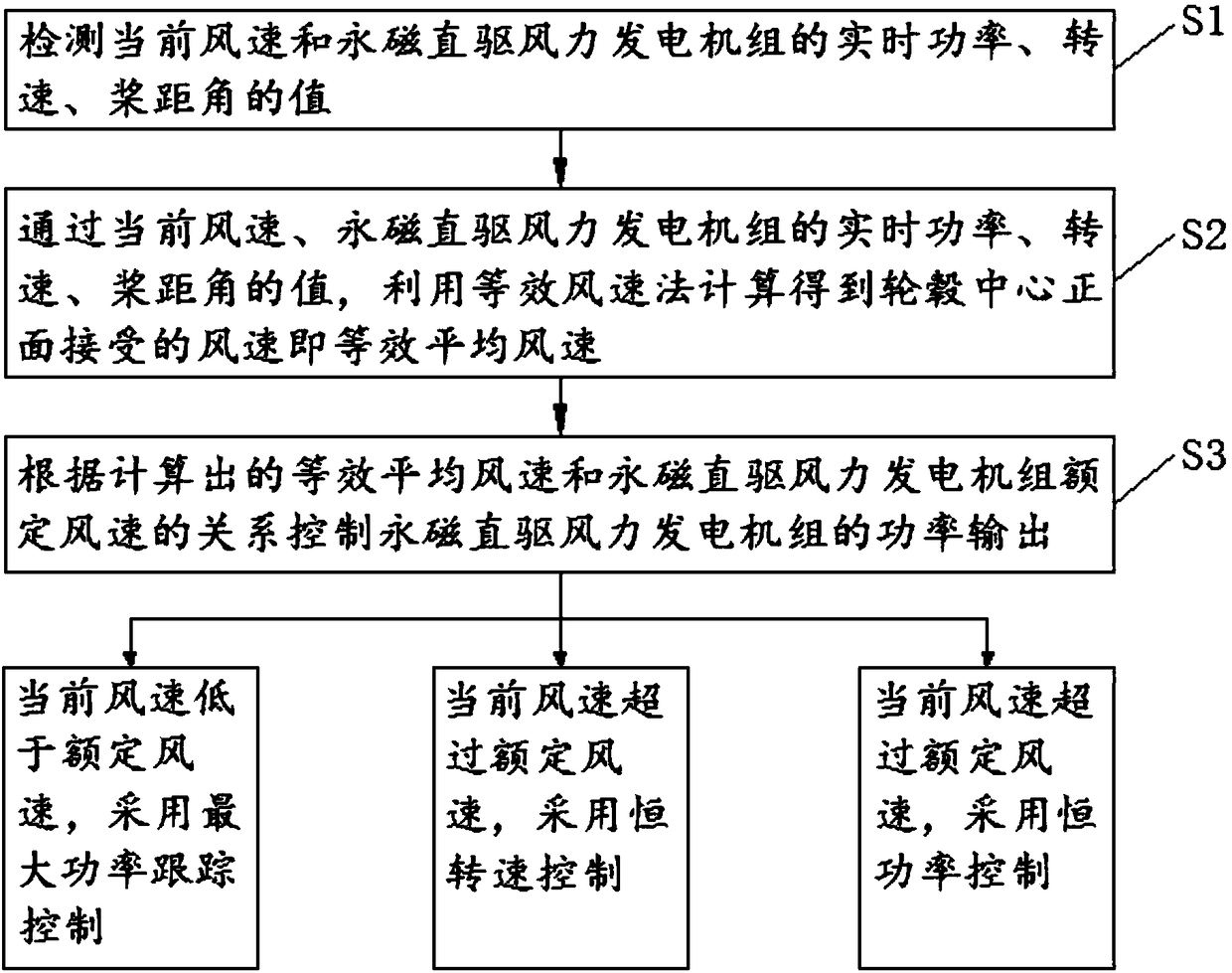

Method used

Image

Examples

Embodiment 1

[0079] Taking the 60kW permanent magnet direct drive wind turbine as an example, the above control method is verified by means of simulation. The simulation software uses GH Bladed software, which is an integrated computational simulation tool for horizontal axis wind turbines of various sizes and types, both onshore and offshore, for performance and load calculations required for design and certification.

[0080] The first choice is to establish a model based on the real data of the 60kW permanent magnet direct-drive wind turbine. According to the above control method, the DLL dynamic link library file is written in the VC++6.0 environment, and the simulation calculation is performed on the external controller of the GH Bladed software.

[0081] Secondly, set the simulation parameters: the communication time is 0.02s (that is, data exchange is performed every 0.02s), the simulation time is 600s, the simulation process uses the 3D turbulent wind defined according to the IEC-61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com