Method for preparing high-quality middle phase asphalt by co-carbonization method

A technology of mesophase pitch and co-carbonization, which is applied in the direction of chemically processing tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of high ash content, reduced mesophase content, increased production cost, etc., and achieves low impurity ash content. , accelerated formation, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

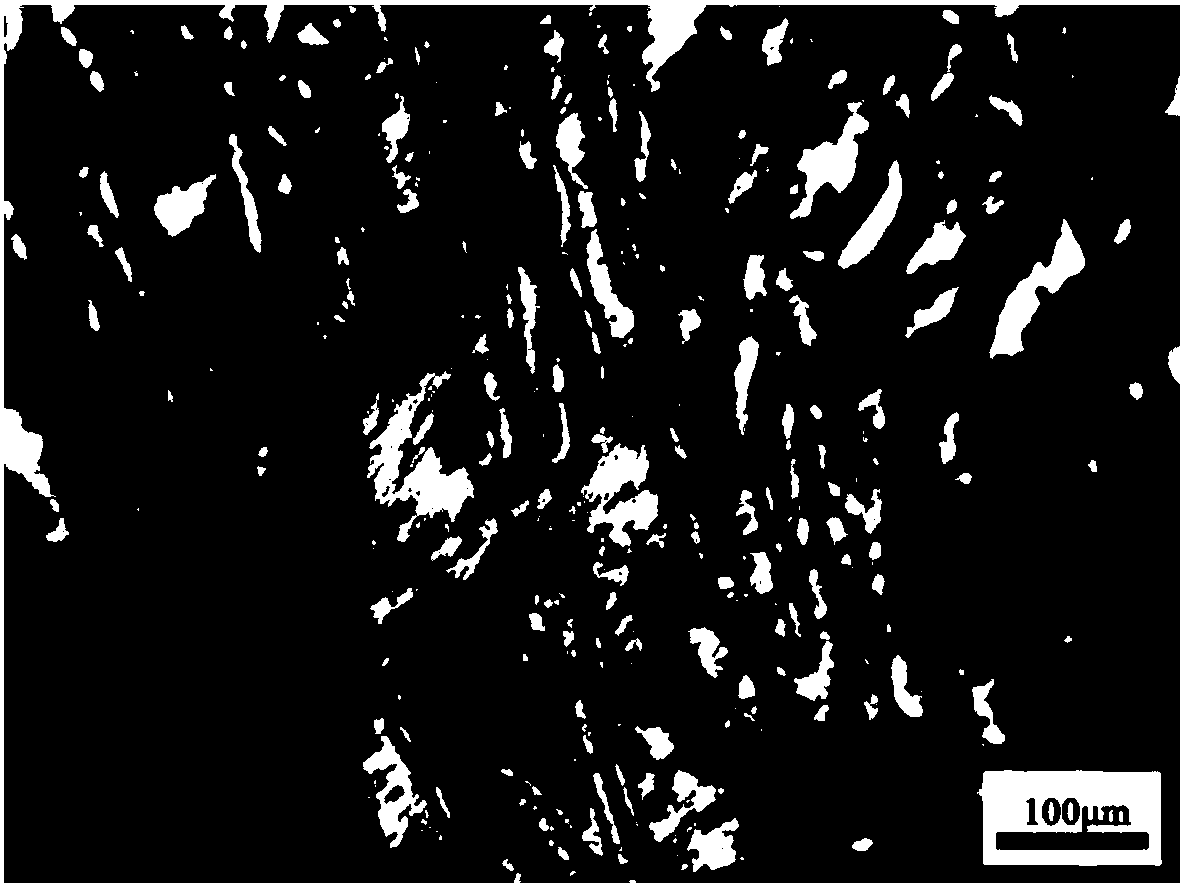

Image

Examples

Embodiment 1

[0025] Put 400g of refined coal tar pitch raw material and 12g of naphthalene-based mesophase pitch additive into a pulverizer for pulverization and mixing, then put the mixture together into a high-temperature and high-pressure reaction kettle, pass through nitrogen to purge and replace the air three times, and then seal the reaction kettle. Nitrogen was passed into the reactor until the initial pressure was 0.2MPa, and the temperature was raised to 400°C at a rate of 3°C / min. When the temperature was greater than 100°C, stirring was started at a stirring rate of 320rmp. When the temperature rose to 400°C, it was kept for 10 hours. During the reaction, keep a closed constant pressure of 1.0MPa, and keep stirring at a constant speed. After the heat preservation is over, the pressure is released, nitrogen is purged for 20 minutes to remove light components, the stirring is stopped, and cooled to room temperature to obtain a wide-area streamlined mesophase pitch product with a so...

Embodiment 2

[0027] Increase the quality of the naphthalene-based mesophase pitch additive from 12g to 20g, and other conditions are the same as in Example 1. The softening point of the wide-area streamlined mesophase pitch product obtained is 260°C, the mesophase content is as high as 99%, and the carbon-hydrogen ratio is 1.86 .

Embodiment 3

[0029] Increase the quality of the naphthalene-based mesophase pitch additive from 12g to 40g, and other conditions are the same as in Example 1. The softening point of the wide-area streamlined mesophase pitch product obtained is 270°C, the mesophase content is as high as 98%, and the carbon-hydrogen ratio is 1.96 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com