Internal and external dynamic heating solid organic matter pyrolysis combination device in double-column mixing process

A technology of solid organic matter and dynamic heating, which is used in the combination of direct and indirect heating for dry distillation, special forms of dry distillation, petroleum industry, etc. High, high productivity, the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

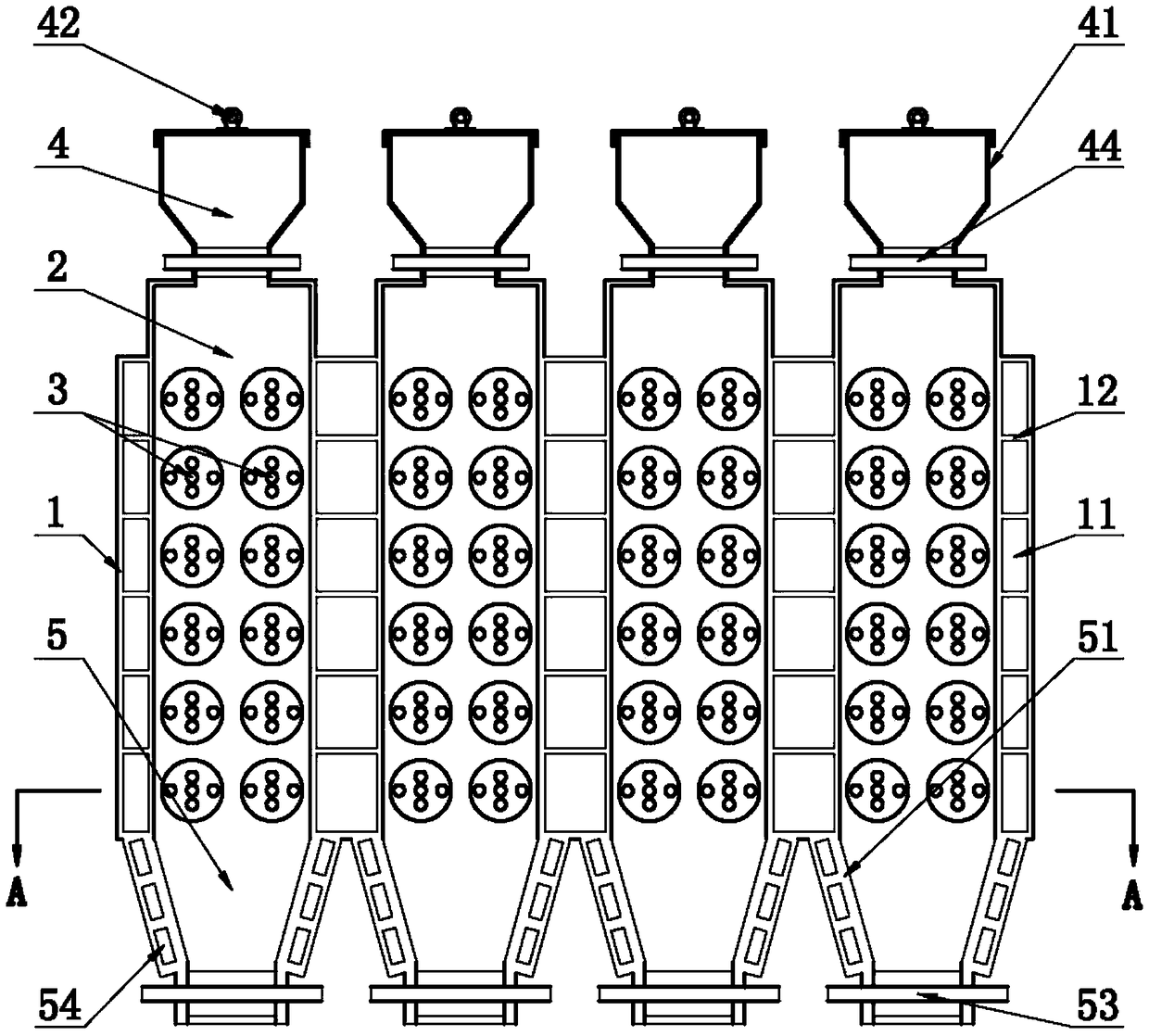

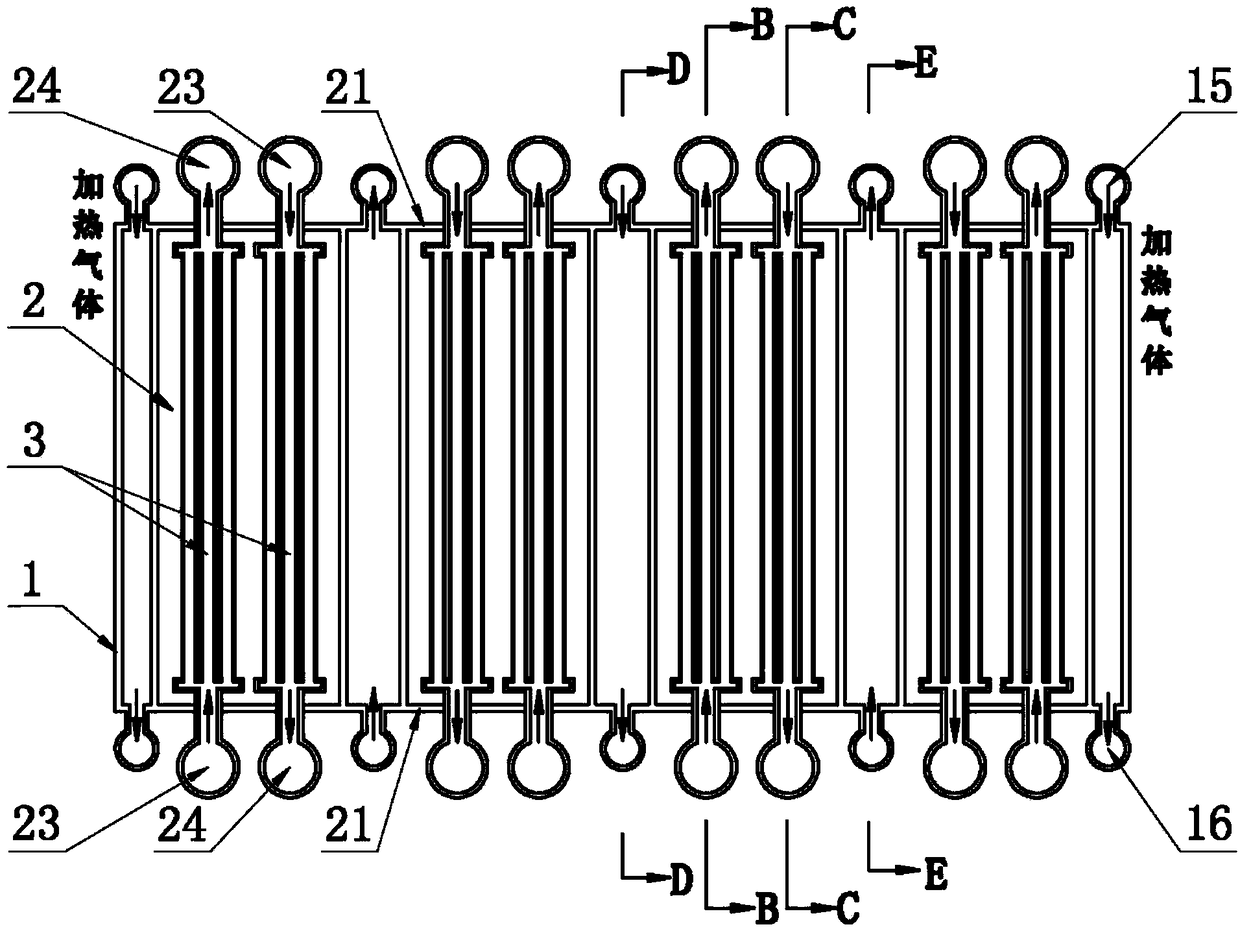

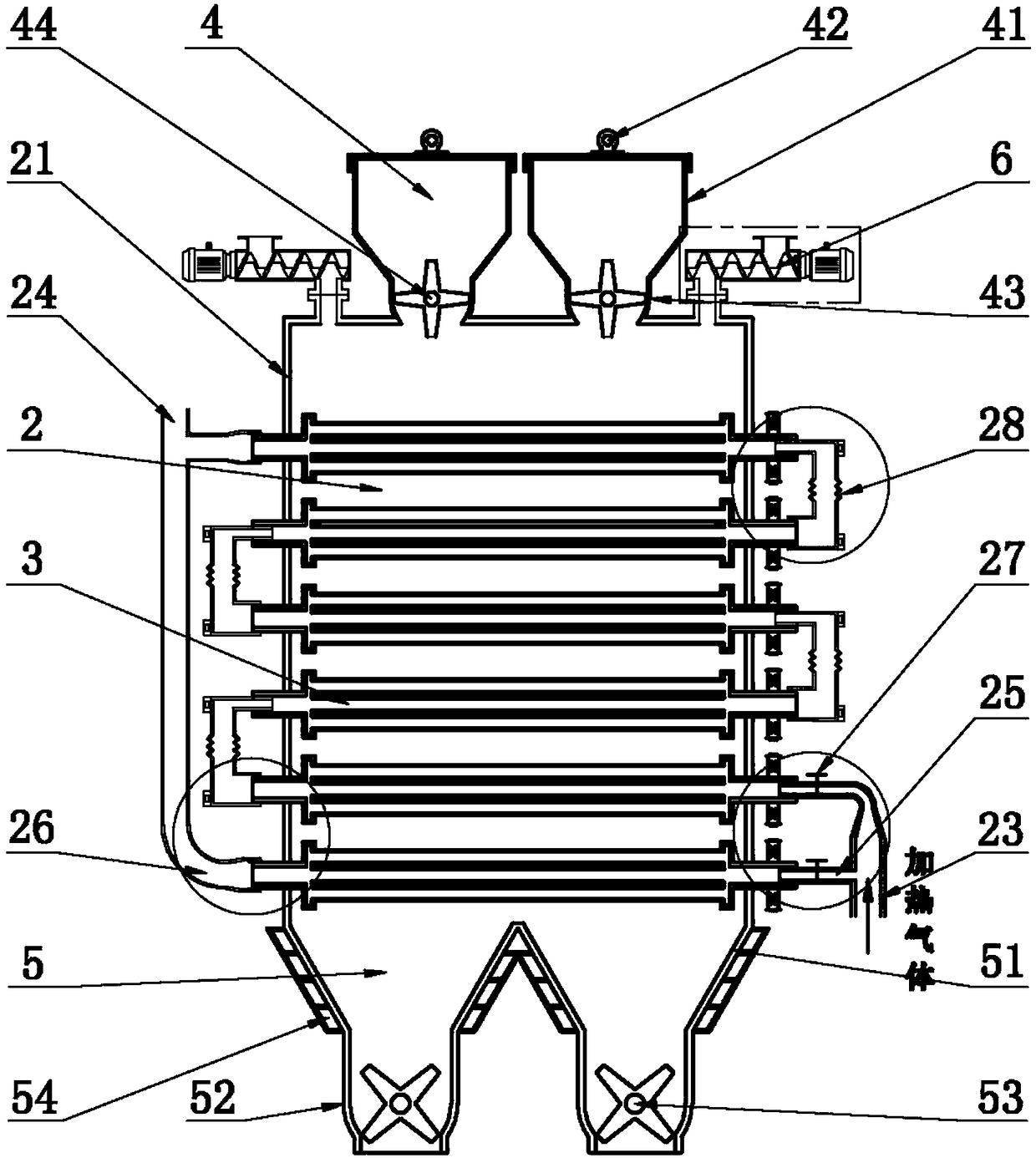

[0059] Such as Figure 1-17 As shown, in order to achieve the above purpose, the developed dual-row mixing process internal and external dynamic heating solid organic pyrolysis combination device is composed of multiple vertical pyrolysis chambers 2 and heating chambers 1 alternately connected in parallel, each vertical pyrolysis chamber 2 Both are rectangular cavities, the left and right sides of which are heating chambers 1 , and the front and rear sides are mixing walls 21 for installing the agitator 3 . Two columns of agitators 3 installed side by side on the mixing wall 3, each column consists of multiple horizontally arranged agitators 3, each agitator 3 is a hollow device, can pass through the heating gas, and multiple agitators 3 pass through The series connection of the connecting pipes 28 can form a multi-process agitator string 22, and the parallel connection of several agitator 3 and the agitator string 22 constitutes different heating modes inside the pyrolysis ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com