Oil-water separator for offshore wind farm

A technology of oil-water separator and wind farm, which is applied in the field of offshore wind power generation, can solve the problems of small amount of mixing, heavy weight, and high energy consumption, and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

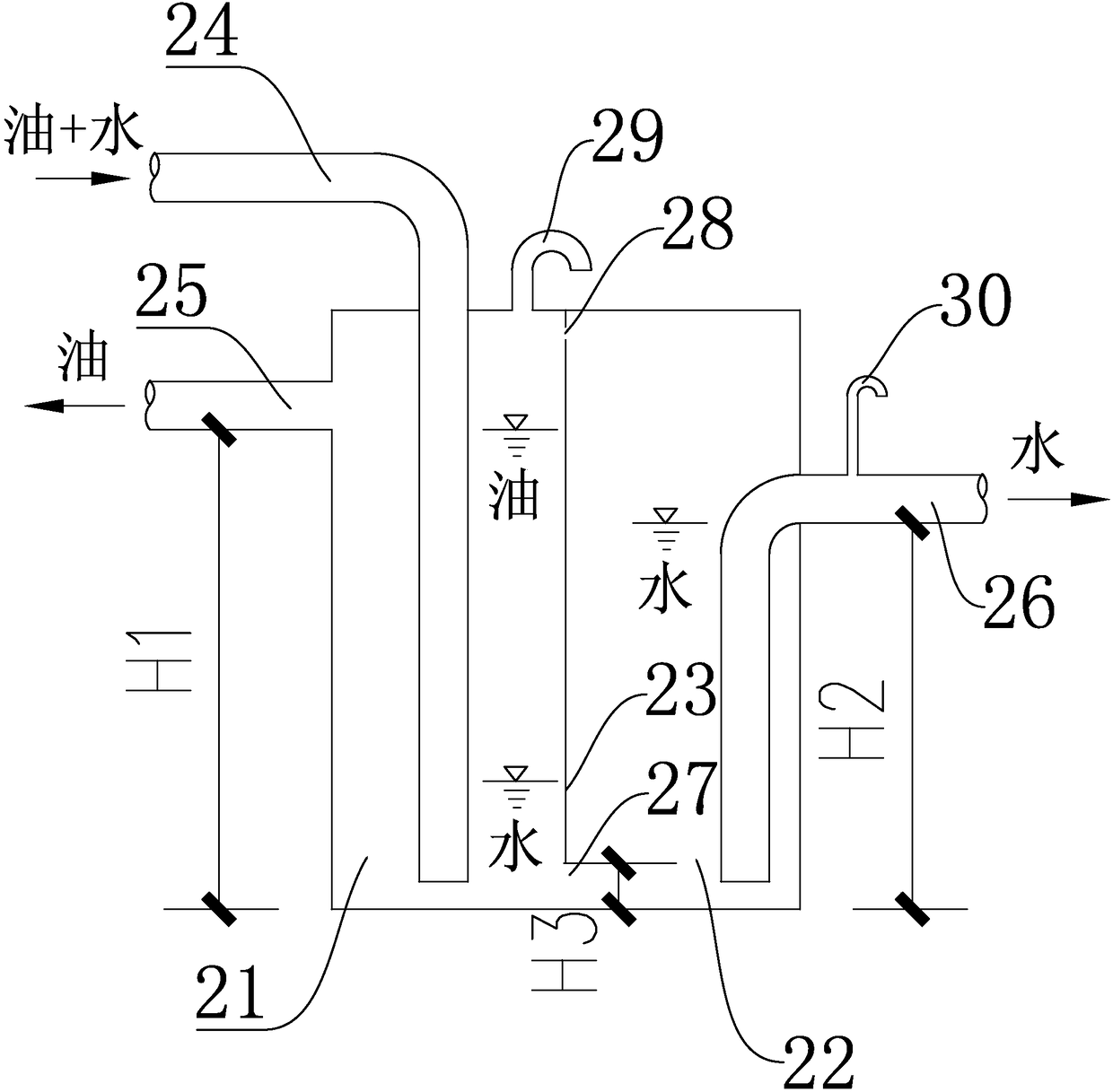

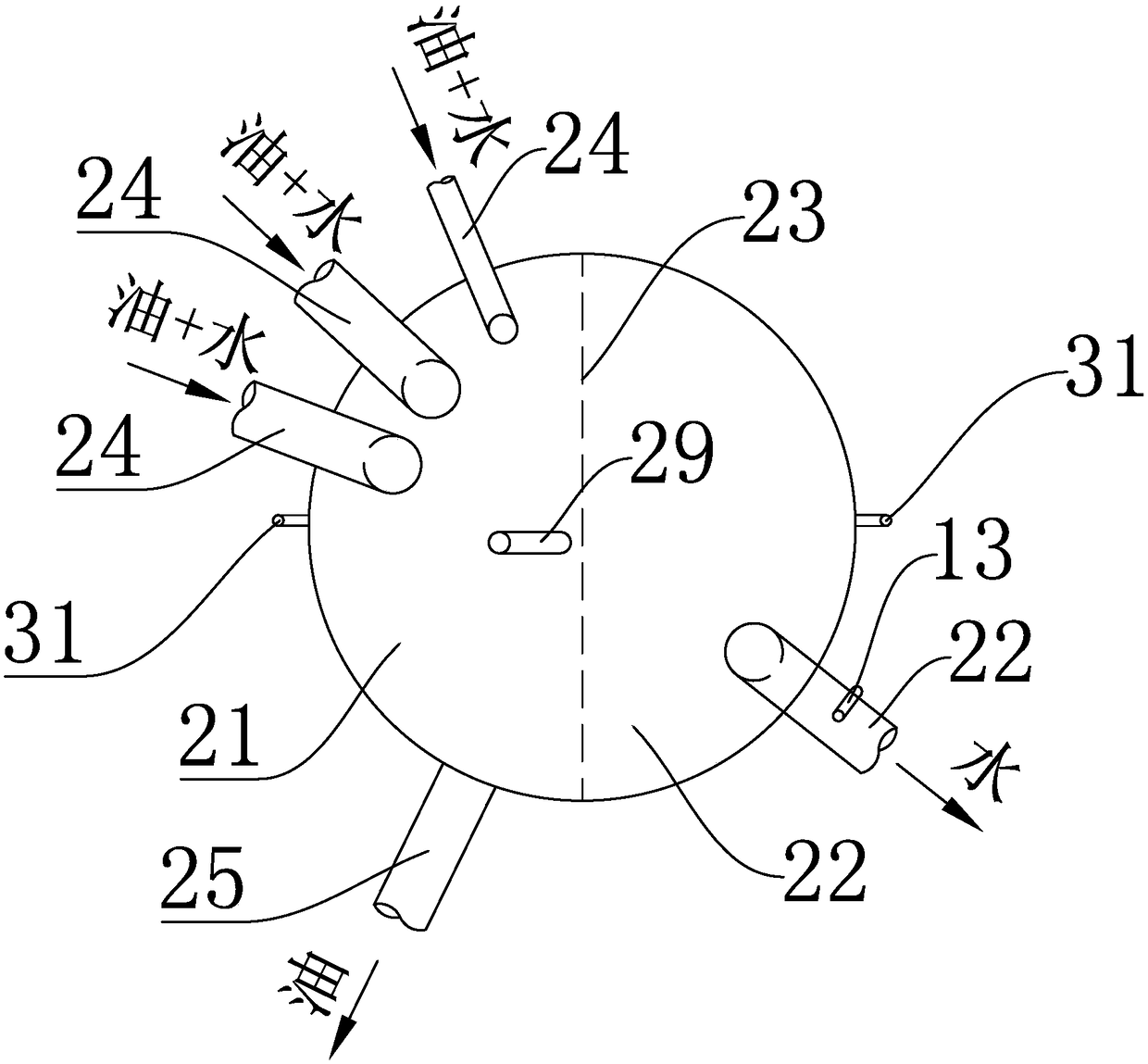

[0026] Such as figure 1 , figure 2 and image 3 As shown, this embodiment is an oil-water separator used in offshore wind farms, which has an oil-water separator 2, which is installed between the main transformer accident oil sump 1 and the emergency oil storage tank 3, and is used to convert the secondary The oil-water mixture discharged from the main transformer accident oil sump 1 is separated, the oil is collected in the accident oil storage tank 3, and the water is discharged. In areas where the water in the oil-water separator 2 can freeze when the lowest temperature is lower than 0°C in winter, it is necessary to install an insulation layer on the outer wall of the oil-water separator 2. Prevent the water in the oil-water separator 2 from freezing in cold regions or in winter, and lose the oil-water separation function.

[0027] In this embodiment, the oil-water separator 2 is a cylindrical structure with a diameter of 1.5 m and a total height of 30 m. The cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com