Spring cleaning equipment and spring cleaning process applying same

A technology for cleaning equipment and cleaning tanks, which is applied in the field of spring cleaning technology and spring cleaning equipment, which can solve the problems of shortening the service life of springs, small spring pitch, corrosion, etc., and achieve the effect of prolonging service life and reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

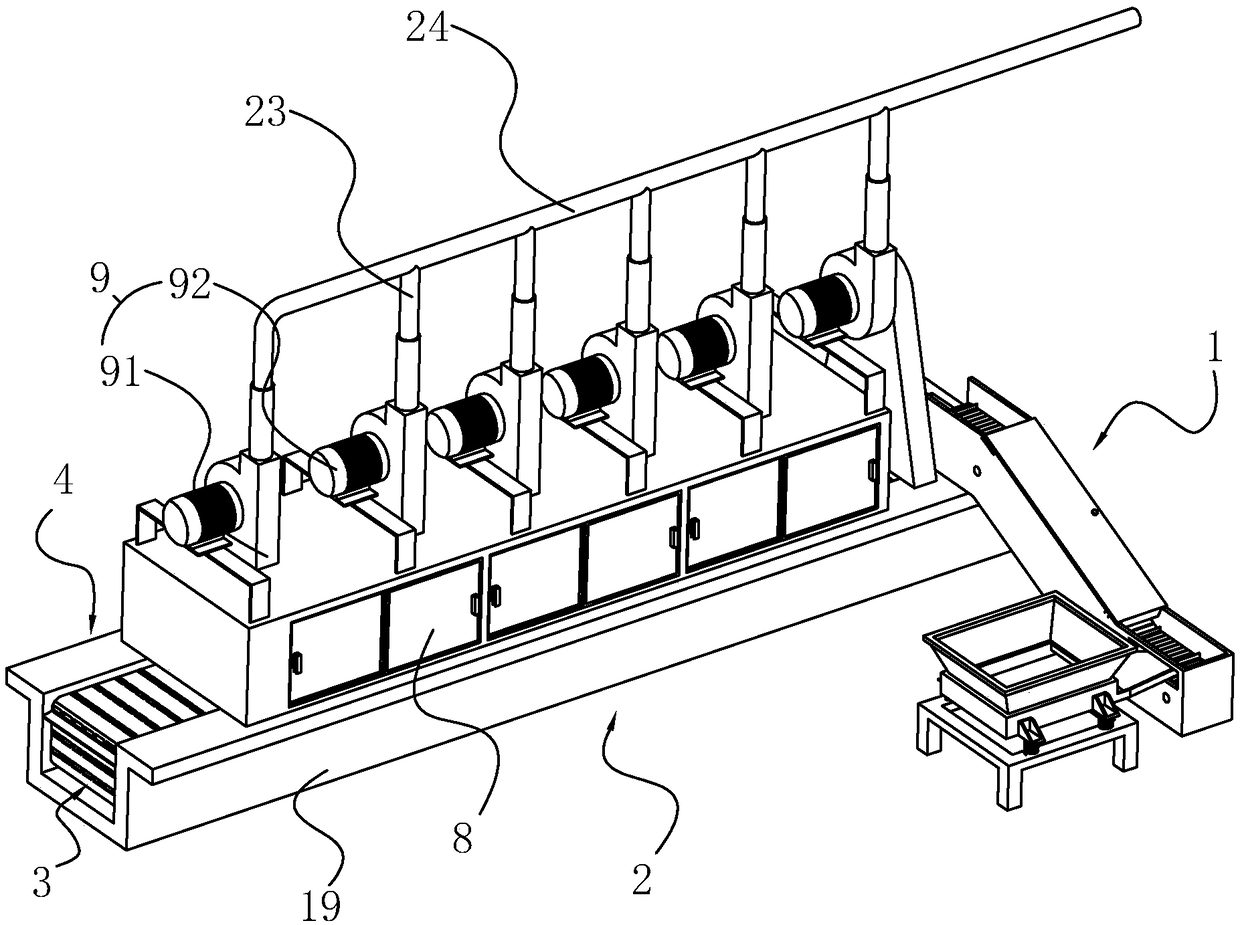

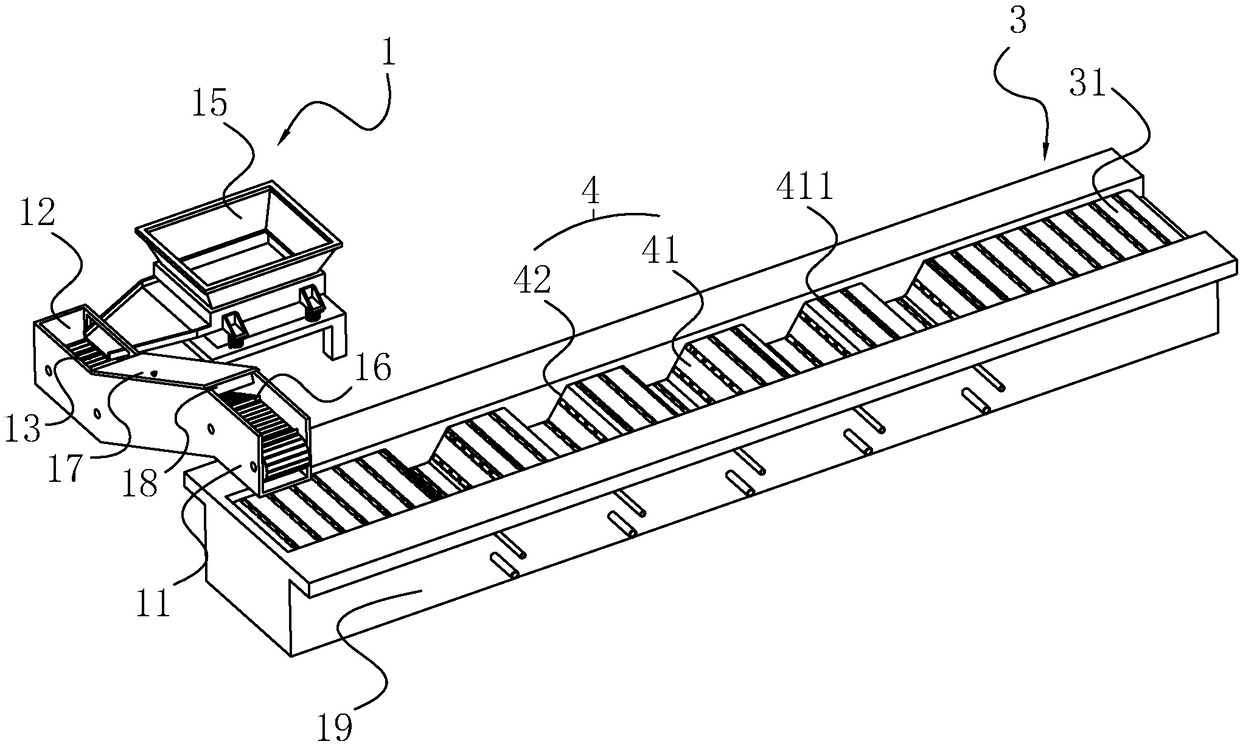

[0046] A spring cleaning equipment, refer to figure 1 As shown, it includes a feeding device 1 for storing a certain amount of springs to be cleaned, a cleaning device for cleaning the springs 2, a feeding device 3 for discharging and unloading the cleaned springs, and a slave cleaning device 2 Extend to the conveying mechanism 4 of the unloading device 3, so that during the cleaning process, the unloading device 3 sends the spring to be cleaned to the conveying mechanism 4, and then the conveying mechanism 4 sequentially passes the springs through the washing device 2, and finally the unloading The device 3 sends out the cleaned spring.

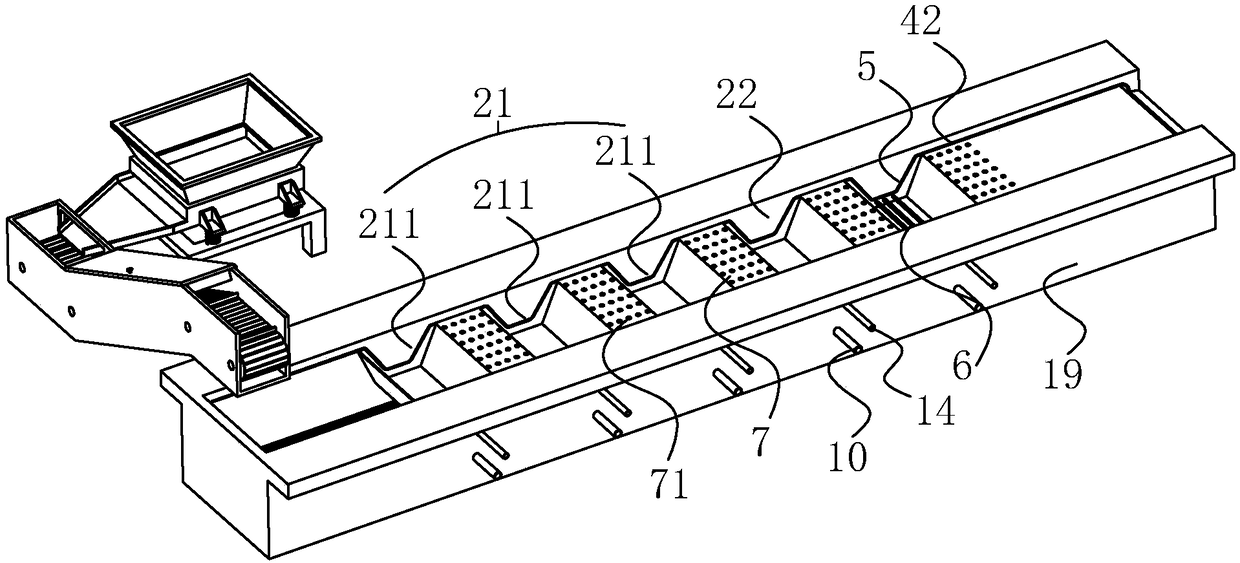

[0047] Reference figure 2 As shown, the cleaning device 2 includes a water washing tank 21 and a dehydration tank 22 arranged in sequence. The water washing tank 21 includes three ultrasonic cleaning tanks 211 arranged in sequence. The ultrasonic cleaning tank 211 is provided with an upper opening, and the bottom of the ultrasonic cleaning tank...

Embodiment 2

[0058] A spring cleaning process, which is characterized in that it includes the following steps:

[0059] Step A: Vibrate to remove solid particles and dust, pour the spring to be cleaned into the vibrating plate to vibrate to remove solid particles and dust;

[0060] Step B: Flatten, use the lifting chain plate 13 to lift the spring that has been vibrated to remove dust, and rely on the scraper 18 to prevent the spring on the lifting chain plate 13 from stacking as much as possible, so that the spring can be laid flat on the conveyor chain plate 41 surface;

[0061] Step C: For the first ultrasonic cleaning, the spring is transported to the first ultrasonic cleaning tank 211 by the conveyor chain 41 for cleaning, and the metal processing part grease cleaner is added to the ultrasonic cleaning tank 211, and the ultrasonic cleaning tank 211 The temperature is maintained at about 50℃;

[0062] Step D: Inhale for the first time, the conveyor chain 41 transports the spring from the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com