Slurry shield construction waste slurry productization forming system

A technology of waste mud and mud water shield, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. It can solve the problems of preparing non-burning bricks from waste mud and achieve excellent separation effect and texture. The effect of uniformity and improvement of disposal level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

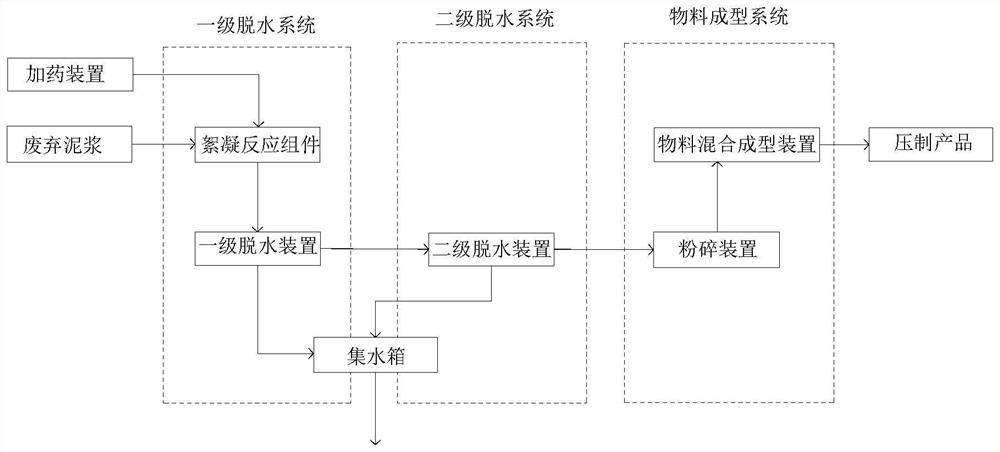

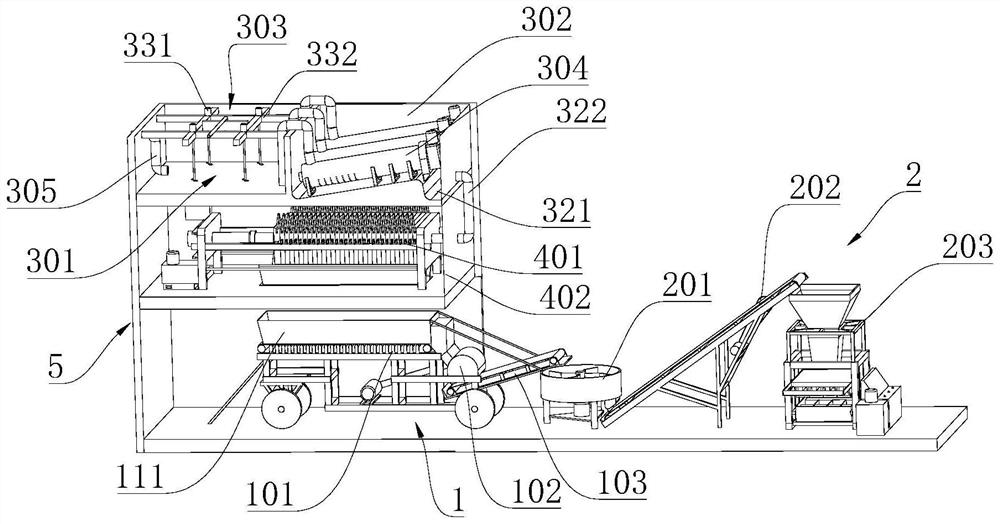

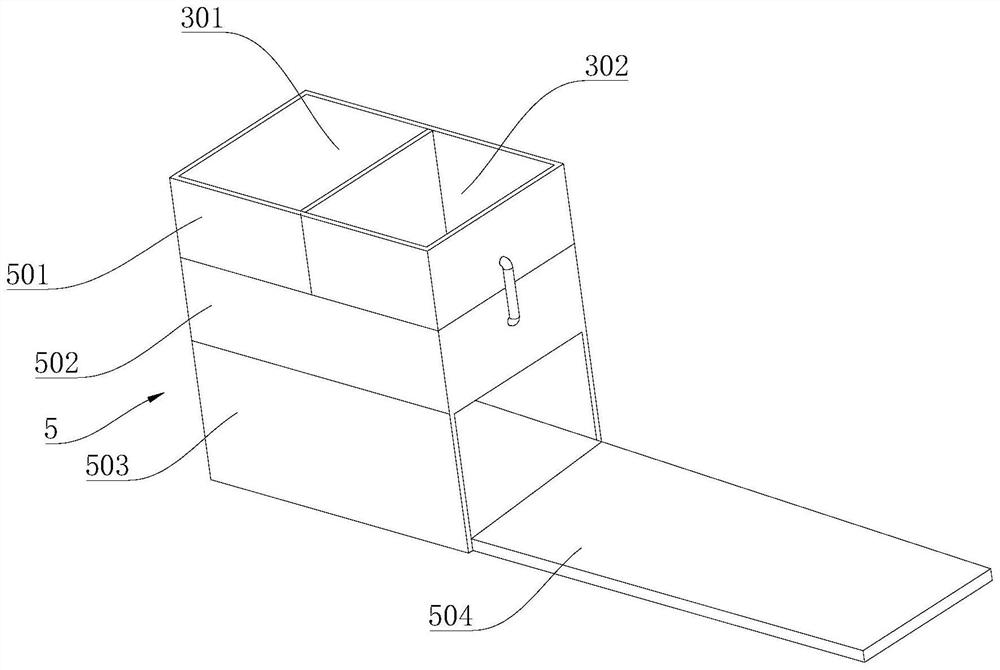

[0037] Please refer to figure 1 , A product forming system for waste mud in mud-water shield construction, which includes a primary dehydration system, a secondary dehydration system and a material forming system that are connected in sequence, and the primary dehydration system, the secondary dehydration system and the material forming system are all arranged on the support On rack 5, the primary dehydration system is used to dehydrate the waste mud to obtain concentrated mud, the secondary dehydration system is used to compress and dehydrate the concentrated mud to obtain mud cake, and the material forming system is used to pulverize the mud cake into mud powder, and add extra The mud powder of the material is mixed and pressed into b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com