Preparation method of carbon nanotube cladded selenium-based catalyst for electrolyzing water to produce hydrogen

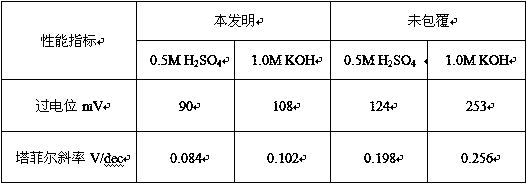

A carbon nanotube and catalyst technology, which is applied in the field of preparation of carbon nanotube-coated selenium-based catalysts for electrolysis of water to produce hydrogen, can solve the problems of ineffective protection of catalyst structure stability, catalyst deactivation, etc., and achieve large material transfer surface , The preparation process is simple, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Weigh selenium dioxide and nickel nitrate according to the molar ratio of 2.5:1, add them to the mixed solution of deionized water and N,N dimethylformamide with a volume ratio of 1:2, stir well, and then place Heated at 185°C for 10 hours to obtain a nickel selenide nanowire material with a length of 200nm and a wire diameter of 3nm;

[0033] (2) Add the nickel selenide nanowires into the diethylene glycol aqueous solution with a pH of 10, control the pressure of the autoclave at 0.5 MPa, carry out carburizing reaction at 300°C for 5 hours in the autoclave, and cool naturally to room temperature , after filtering, the pretreated material is obtained;

[0034] (3) Wash and dry the pretreated material with anhydrous ethanol, protect it with inert gas argon, and sinter it in a muffle furnace for 2 hours at a temperature of 500°C, soak it in hydrofluoric acid with a concentration of 10% for 12 hours Afterwards, rinse and dry with deionized water, and finally heat-treat...

Embodiment 2

[0037] (1) Weigh selenium dioxide and cobalt sulfate according to the molar ratio of 2.2:1, add them to the mixed solution of deionized water and N,N dimethylformamide with a volume ratio of 1:2, stir well, and then place Heated at 179°C for 13 hours to obtain a cobalt selenide nanowire material with a length of 1000nm and a wire diameter of 15nm;

[0038] (2) Add the cobalt selenide nanowires into the diethylene glycol aqueous solution with a pH of 10, control the pressure of the autoclave at 1.2MPa, carry out carburizing reaction at 280°C for 5h in the autoclave, and cool naturally to room temperature , after filtering, the pretreated material is obtained;

[0039] (3) The pretreated material was washed and dried with absolute ethanol, protected with nitrogen, and sintered in a muffle furnace for 2 hours at a sintering temperature of 500°C. Rinse with ionized water, wash and dry, and finally heat-treat at 800°C for 2 hours to obtain a cobalt selenide catalyst with a composi...

Embodiment 3

[0042] (1) Weigh selenium dioxide and ferric chloride according to the molar ratio of 2:1, add them to the mixed solution of deionized water and N,N dimethylformamide with a volume ratio of 1:2, stir evenly, and then Heat at 178°C for 12 hours to obtain iron selenide nanowire materials with a length of 1000nm and a wire diameter of 6nm;

[0043] (2) Add iron selenide nanowires into diethylene glycol aqueous solution with a pH of 9, control the pressure of the autoclave at 0.9MPa, and carry out carburizing reaction at 240°C for 4.1h in the autoclave, and cool naturally to room temperature. After filtering, the pretreated material is obtained;

[0044] (3) Wash and dry the pretreated material with absolute ethanol, protect it with inert gas argon, and sinter in a muffle furnace for 2 hours at a sintering temperature of 500°C, using hydrofluoric acid with a concentration of 10-15% After soaking for 12 hours, wash and dry with deionized water, and finally heat-treat at 800°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com