A kind of purification equipment and purification method of photocatalyst and volatile organic compound

A technology of photocatalyst and purification equipment, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low degradation and mineralization activity, easy deactivation, desorption and secondary pollution, etc., to achieve High degradation and mineralization efficiency, simple optimization of preparation process, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of photocatalyst

[0030] (1) Manganese sulfate, TiO 2 Mix with water at a mass ratio of 1: 10: 20, and after ultrasonication for 30 minutes, a transparent first mixed solution is obtained;

[0031] (2) Stir the first mixed solution at a speed of 50 rpm for 200 min to obtain the second mixed solution;

[0032] (3) Put the foamed nickel into the second mixed solution, soak it for 120min, seal the wetted nickel foam with tinfoil and react at 40°C for 5h to obtain Mn-doped TiO 2 The composite material is supported on the surface of nickel foam to form a photocatalyst.

[0033] 2. Build equipment for volatile organic compounds

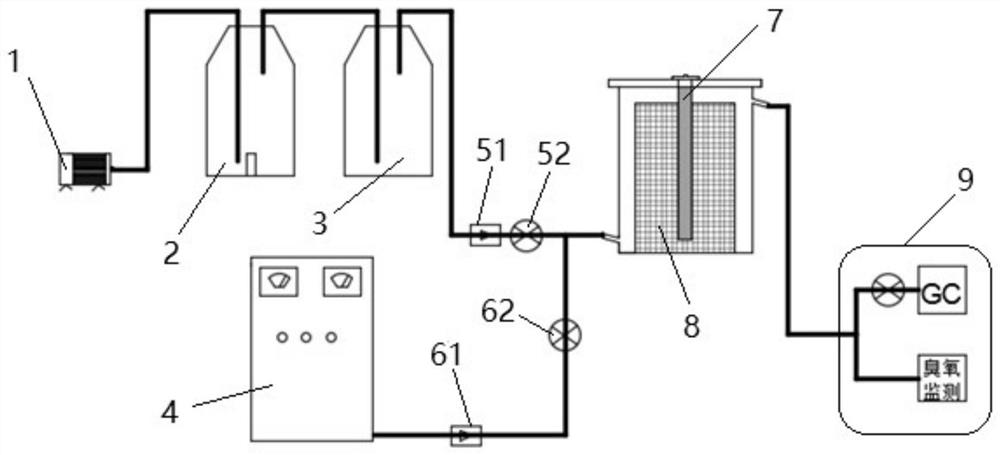

[0034] Such as figure 1 As shown, the purification equipment of the present invention includes: a photocatalytic reactor, an ozone supply system, a sample supply system and an ultraviolet lamp tube, the photocatalytic reactor is a hollow structure, and a photocatalyst is loaded on its inner wall, and the ultraviolet lamp tube It ...

Embodiment 2

[0053] 1. Preparation of photocatalyst

[0054] (1) Cobalt chloride, TiO 2 Mix with water at a mass ratio of 1: 100: 100, and after ultrasonication for 5 minutes, a transparent first mixed solution is obtained;

[0055] (2) Stir the first mixed solution at a speed of 100 rpm for 30 minutes to obtain the second mixed solution;

[0056] (3) Put the foam ceramics into the second mixed solution, soak for 720min, seal the wet foam ceramics with tinfoil paper and react at 300°C for 20h to obtain Co-doped TiO 2 The composite material is supported on the surface of the foamed ceramics to form a photocatalyst.

[0057] 2. Build equipment for volatile organic compounds

[0058] The difference between this step and Example 1 is that the photocatalyst is Co-doped TiO 2 Composite material; other places are basically similar to embodiment 1, and will not be repeated here.

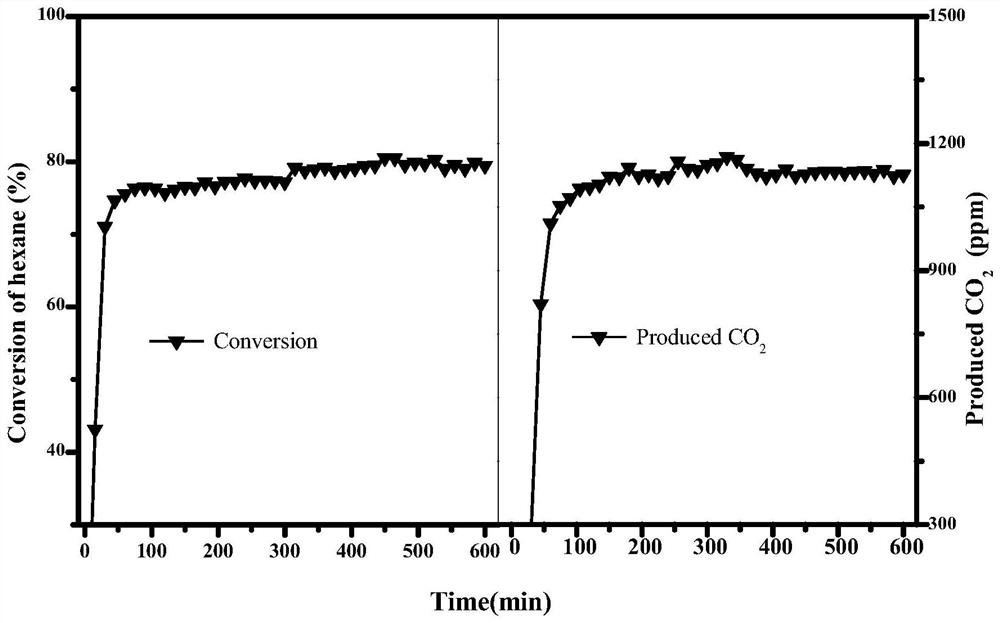

[0059] It has been determined that using the equipment of this embodiment, the average removal rate of volatile o...

Embodiment 3

[0064] 1. Preparation of photocatalyst

[0065] (1) Ferric nitrate, TiO 2 Mix with water at a mass ratio of 1: 10: 50, and obtain a transparent first mixed solution after ultrasonication for 60 min;

[0066] (2) Stir the first mixed solution at a speed of 10 rpm for 360 min to obtain the second mixed solution;

[0067] (3) Put the foamed carbon material into the second mixed solution, soak it for 30 minutes, seal the wet foamed carbon material with tinfoil paper and react at 100°C for 1 hour to obtain Fe-doped TiO 2 The photocatalyst formed on the surface of the composite material loaded on the foamed carbon material.

[0068] 2. Build equipment for volatile organic compounds

[0069] The difference between this step and Example 1 is that the photocatalyst is Fe-doped TiO 2 Composite material; other places are basically similar to embodiment 1, and will not be repeated here.

[0070] It has been determined that using the equipment of this embodiment, the average removal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com