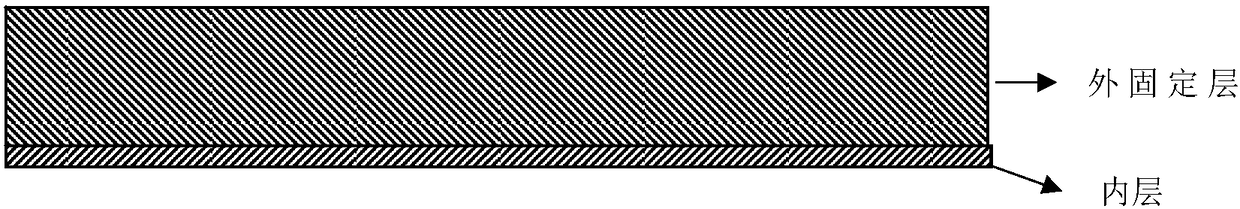

Medical external fixation multilayer material with shape memory and high thermal conductivity and preparation method thereof

A multi-layer material and external fixation technology, applied in the field of medical materials, can solve the problems of low efficiency, decreased tensile strength and elongation at break of polycaprolactone, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0024] (1) Take by weight 100 parts of polycaprolactone PDL-20A, 25 parts of polyethylene oxide WSR-303, 5 parts of glycerol, 1 part of nano-silver supported graphene microsheets, 0.5 part of 2 , 4,6-trimethylbenzoyl-diphenylphosphine oxide crosslinking agent and 0.1 part of photodecomposition accelerator UV-O, at a temperature of 23°C to 25°C, stir and mix at a speed of 100r / min Uniformly, premix A is prepared;

[0025] (2) Weigh 100 parts by weight of silicone rubber TPGC-MY-918, 1 part of graphene microflakes supported by nano-silver, 0.1 part of photodecomposition accelerator UV-O and 0.5 part of 2,4,6-tri Toluyl-diphenylphosphine oxide cross-linking agent, at a temperature of 23°C to 25°C, stir and mix at a speed of 100r / min to prepare premix B;

[0026] (3) Put premix A and premix B into the FJLBIII series multi-layer c...

Embodiment 2

[0031] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0032] (1) Take by weight 100 parts of polycaprolactone PDL-20A, 25 parts of polyethylene oxide WSR-303, 8 parts of glycerol, 3 parts of nano-silver loaded graphene microsheets, 0.5 parts of 2 -Hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-acetone cross-linking agent and 0.08 parts of photodecomposition accelerator UV-9, at a temperature of 23°C to 25°C Under conditions, stir and mix evenly at a speed of 150r / min to prepare premix A;

[0033] (2) 2-methyl-2-(4) of 100 parts of silicone rubber TPGC-MY-918, 5 parts of nano-silver supported graphene microsheets, 0.1 part of photodecomposition accelerator RMB and 0.5 parts by weight -Morpholinyl)-1-[4-(methylthio)phenyl]-1-acetone cross-linking agent, under the temperature condition of 23 ℃ ~ 25 ℃, stir and mix evenly at a speed of 150r / min to prepare the pre- mixture B;

[0...

Embodiment 3

[0039] A method for preparing a shape-memory high thermal conductivity medical external fixation multilayer material, comprising the following steps:

[0040] (1) Weigh 100 parts by weight of polycaprolactone Solvay 6800, 30 parts of PEO-90M, 10 parts of glycerin, 5 parts of nano-silver loaded graphene microflakes, 1 part of 2-dimethylamino- 2-benzyl-1-[4-(4-morpholinyl)phenyl]-1-butanone crosslinking agent and 0.3 parts of photodecomposition accelerator UVP-327, under the temperature conditions of 23°C to 25°C, Stir and mix evenly at a speed of 150r / min to prepare premix A;

[0041] (2) Weigh 100 parts by weight of silicone rubber MM71791 / 50U, 3 parts of nano-silver supported graphene microflakes, 0.3 parts of photodecomposition accelerator RMB and 1 part of 1-hydroxycyclohexyl phenyl ketone crosslinking agent, at a temperature of 23°C to 25°C, stir and mix evenly at a speed of 150r / min to prepare premix B;

[0042] (3) Put premix A and premix B into the FJLBIII series mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com