Degradable sludge-based seedling pot and preparation method thereof

A technology for raising seedlings and sludge, which is applied in the field of agricultural appliances, can solve the problems of high energy consumption, poor environmental friendliness and high preparation cost in the preparation process, and achieve the effects of shortening degradation time, improving mechanical properties and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

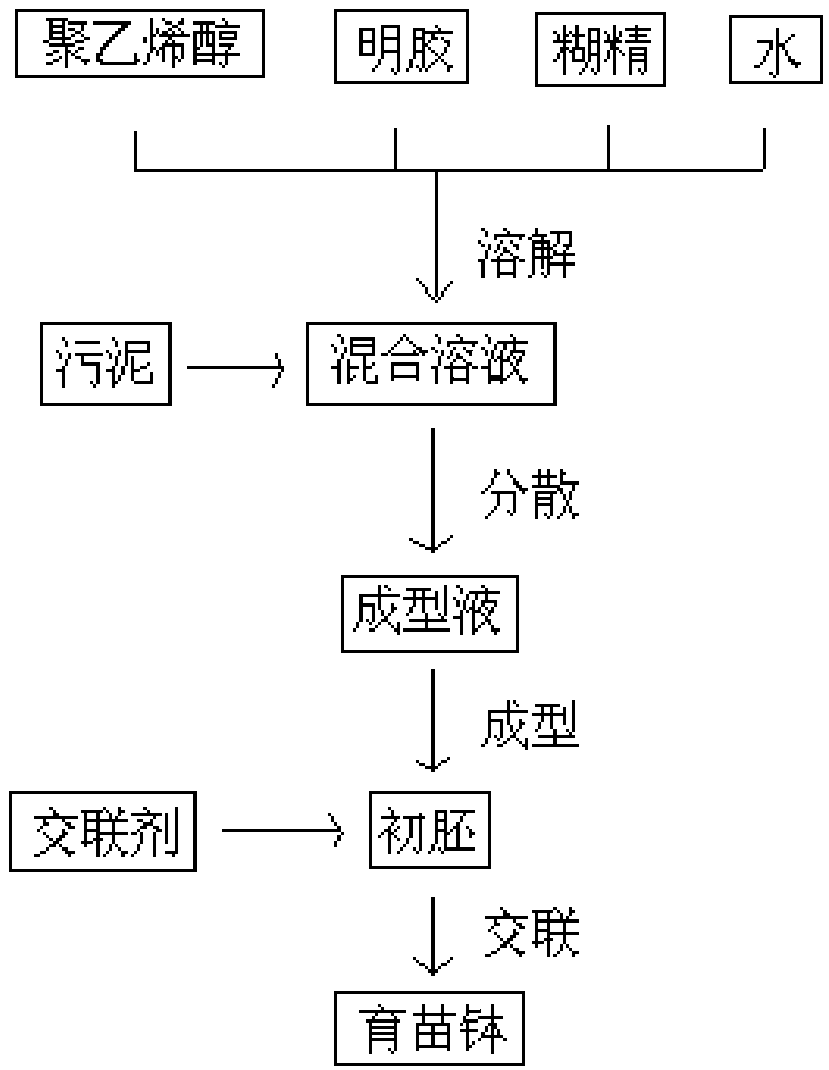

Image

Examples

Embodiment 1

[0030] 1. Dissolving and dispersing treatment: add 3 parts by weight of polyvinyl alcohol into 90 parts by weight of water, and dissolve completely at 95°C to prepare an aqueous solution of polyvinyl alcohol; at 75°C, add 8 parts by weight of After the gelatin is completely dissolved, add 8 parts by weight of dextrin and stir until it is evenly mixed to obtain a mixed solution; add 15 parts by weight of harmless treated sludge at 65°C, stir and disperse evenly to obtain a molding solution ;

[0031] 2. Molding treatment: Pour the molding liquid into the mold, water-cool to room temperature, and make the first embryo;

[0032] 3. Cross-linking treatment: react the primordial with epichlorohydrin at 55° C. for 6 hours; wash with anhydrous ether and deionized water after cross-linking to obtain a degradable sludge-based seedling pot.

Embodiment 2

[0034] 1. Dissolving and dispersing treatment: add 2 parts by weight of polyvinyl alcohol into 80 parts by weight of water, and dissolve completely at 90°C to prepare an aqueous solution of polyvinyl alcohol; at 80°C, add 5 parts by weight of After the gelatin is completely dissolved, add 10 parts by weight of dextrin and stir until it is evenly mixed to obtain a mixed solution; add 5 parts by weight of harmless treated sludge at 70°C, stir and disperse evenly to obtain a molding solution ;

[0035] 2. Molding treatment: Pour the molding liquid into the mold, water-cool to room temperature, and make the first embryo;

[0036] 3. Cross-linking treatment: the first embryo was cross-linked with formaldehyde at 60° C. for 5 hours; after the cross-linking was completed, it was washed with absolute ethanol and deionized water to obtain a degradable sludge-based seedling pot.

Embodiment 3

[0038] 1. Dissolving and dispersing treatment: add 5 parts by weight of polyvinyl alcohol into 100 parts by weight of water, and dissolve completely at 100°C to prepare an aqueous solution of polyvinyl alcohol; at 70°C, add 10 parts by weight of After the gelatin is completely dissolved, add 5 parts by weight of dextrin and stir until it is evenly mixed to obtain a mixed solution; add 20 parts by weight of harmless treated sludge at 60°C, stir and disperse evenly to obtain a molding solution ;

[0039] 2. Molding treatment: Pour the molding liquid into the mold, water-cool to room temperature, and make the first embryo;

[0040] 3. Cross-linking treatment: react the primordial embryo with acetaldehyde at 50° C. for 5-8 hours; wash with absolute ethanol and deionized water after cross-linking to obtain a degradable sludge-based seedling pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com