A method for preparing a hemt device nano-gate

A device and nanotechnology, which is applied in the field of preparation of nanometer gates of HEMT devices, can solve the problems of complex process and expensive equipment, and achieve the effects of simple process, low cost and small gate electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

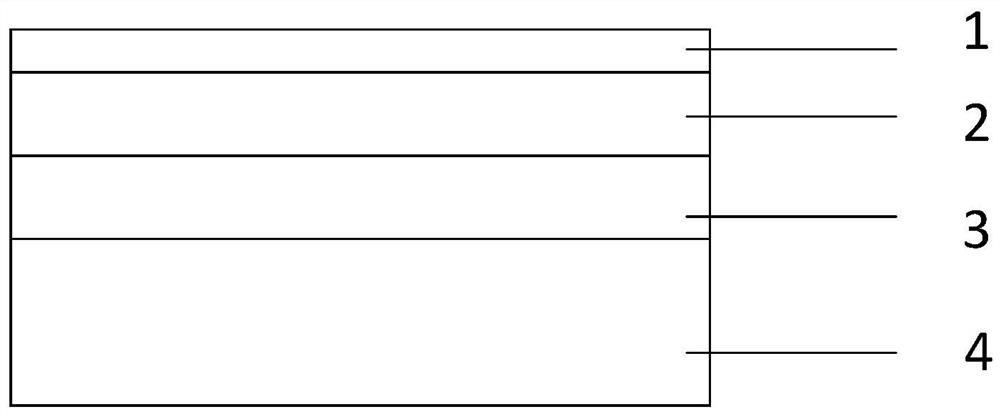

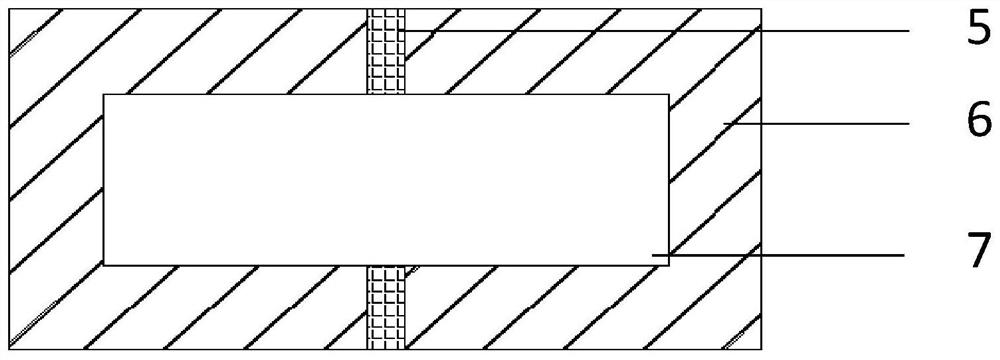

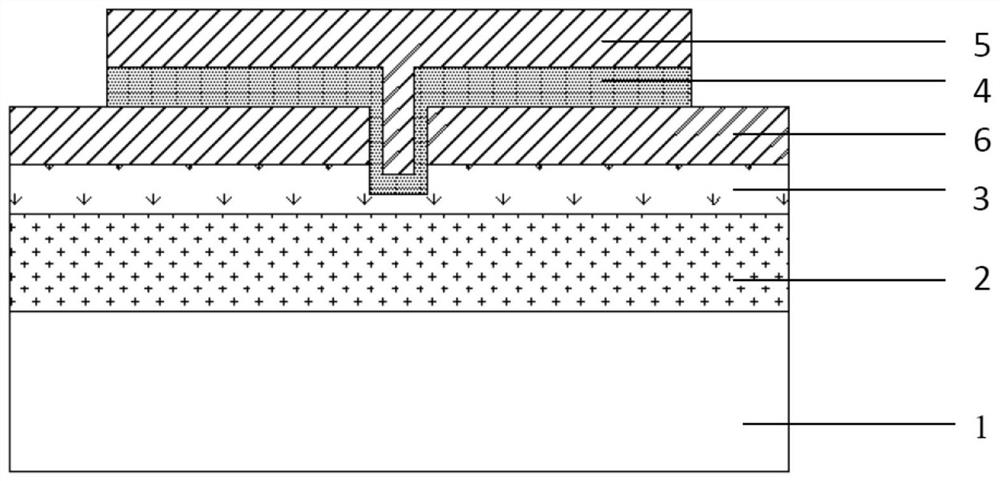

[0045] In the preparation method of the HEMT device nano-gate of the present embodiment, in the manufacturing process of the HEMT device, Ag nanowires are used as a mask to deposit metal on the source and drain electrodes; 3 ·H 2 O, H 2 o 2 、H 2 The method of ultrasonic cleaning of O mixed solution removes the Ag nanowires, forms a slit equivalent to the size of the Ag nanowires between the source and drain electrodes, and finally prepares a nano-gate electrode in the slit, which specifically includes the following steps:

[0046] (1) Clean the surface of the HEMT heterojunction epitaxial wafer: use acetone, ethanol, O 2 The method of plasma purging is cleaned;

[0047] (2) The ethanol solution dispersed with Ag nanowires is slowly dropped on the surface of the HEMT epitaxial wafer, and the ethanol is completely volatilized; the diameter of the Ag nanowires is 80nm, and the length is 100um;

[0048] (3) the epitaxial wafer that step (2) obtains is placed in 10 -5In the v...

Embodiment 2

[0062] In the preparation method of the HEMT device nano-gate of the present embodiment, in the manufacturing process of the HEMT device, Ag nanowires are used as a mask to deposit metal on the source and drain electrodes; 3 ·H 2 O, H 2 o 2 、H 2 The method of ultrasonic cleaning of O mixed solution removes the Ag nanowires, forms a slit equivalent to the size of the Ag nanowires between the source and drain electrodes, and finally prepares a nano-gate electrode in the slit, which specifically includes the following steps:

[0063] (1) Clean the surface of the HEMT heterojunction epitaxial wafer: use acetone, ethanol, O 2 The method of plasma purging is cleaned;

[0064] (2) The ethanol solution dispersed with Ag nanowires is slowly dropped on the surface of the HEMT epitaxial wafer, and the ethanol is completely volatilized; the diameter of the Ag nanowires is 50nm, and the length is 50um;

[0065] (3) the epitaxial wafer that step (2) obtains is placed in 10 -5 In the v...

Embodiment 3

[0074] In the preparation method of the HEMT device nano-gate of the present embodiment, in the manufacturing process of the HEMT device, Ag nanowires are used as a mask to deposit metal on the source and drain electrodes; 3 ·H 2 O, H 2 o 2 、H 2 The method of ultrasonic cleaning of O mixed solution removes the Ag nanowires, forms a slit equivalent to the size of the Ag nanowires between the source and drain electrodes, and finally prepares a nano-gate electrode in the slit, which specifically includes the following steps:

[0075] (1) Clean the surface of the HEMT heterojunction epitaxial wafer: use acetone, ethanol, O 2 The method of plasma purging is cleaned;

[0076] (2) Slowly drop the ethanol solution dispersed with Ag nanowires on the surface of the HEMT epitaxial wafer, until the ethanol is completely volatilized; the Ag nanowires have a diameter of 100nm and a length of 200um;

[0077] (3) the epitaxial wafer that step (2) obtains is placed in 10 -5 ~10 -6 In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com