A polydiacetylene-based thermally reversible color-reversing composite material and its preparation method

A technology of composite materials and diacetylene, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems that the color cannot be restored from red to blue state, and affect the reusability of polydiacetylene sensors, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the preparation of polydiacetylene / hydroxy aluminum oxide composite material

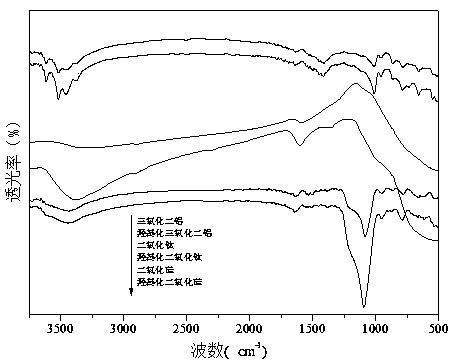

[0022] (1) Preparation of hydroxylated aluminum oxide: Weigh 3 g of aluminum oxide and add to 30 ml H 2 o 2 / H 2 O mixed solution (H 2 o 2 :H 2 O=1:2~1:3v / v), add sodium silicate to adjust the pH of the solution to 10, react at 50°C for 5~7 h, filter, and wash the solid with deionized water several times until the eluate is neutral properties, vacuum drying, that is, hydroxylated aluminum oxide; the infrared spectrum of hydroxylated aluminum oxide and unhydroxylated aluminum oxide is shown in figure 1 .

[0023] (2) Preparation of polydiacetylene / hydroxylated aluminum oxide composite material: Weigh 12 g of 10,12-pentacosadiynoic acid monomer, add it into 1 mL of dimethyl sulfoxide and stir to fully dissolve it Finally, add 9 mL of deionized water, ultrasonically disperse for 10 min, add the above deionized aqueous solution of 3 mg of hydroxylated aluminum oxide, mix and...

Embodiment 2

[0025] Embodiment 2, preparation of polydiacetylene / hydroxylated titanium dioxide composite material

[0026] (1) Preparation of hydroxylated aluminum oxide: Weigh 3 g titanium dioxide particles, add to 30 ml H 2 o 2 / H 2 O mixed solution (H 2 o 2 :H 2 O=1:2~1:3v / v), add sodium silicate to adjust the pH of the solution to 10, react at 50°C for 5~7 h, filter, and wash the solid with deionized water several times until the eluate is neutral properties, and dried in vacuum to obtain hydroxylated titanium dioxide; the infrared spectra of hydroxylated titanium dioxide and unhydroxylated titanium dioxide are shown in figure 1 .

[0027] (2) Preparation of polydiacetylene / hydroxylated titanium dioxide composite material: Weigh 12 g of 10,12-pentacosadiynoic acid monomer, add it into 1 mL of dimethyl sulfoxide and stir to fully dissolve it, then add 9 mL deionized water, after ultrasonic dispersion for 10min, add the above deionized aqueous solution of 3 mg hydroxylated titani...

Embodiment 3

[0029] Embodiment 3, preparation of polydiacetylene / hydroxylated silica composite material

[0030] (1) Preparation of hydroxylated silica: Weigh 3 g of silica particles, add to 30 ml H 2 o 2 / H 2 O mixed solution (H 2 o 2 :H 2 O=1:2~1:3v / v), add sodium silicate to adjust the pH of the solution to 10, react at 50°C for 5~7 h, filter, and wash the solid with deionized water several times until the eluate is neutral properties, and dried in vacuum to obtain hydroxylated silicon dioxide; the infrared spectra of hydroxylated silicon dioxide and unhydroxylated silicon dioxide are shown in figure 1 .

[0031] (2) Preparation of polydiacetylene / hydroxylated silica composite material: Weigh 12 g of 10,12-pentacosadiynoic acid monomer, add 1 mL of dimethyl sulfoxide and stir to fully dissolve, then add 9 mL deionized water, after ultrasonic dispersion for 10 min, add the above deionized aqueous solution of 3 mg hydroxylated silicon dioxide, mix and ultrasonically shake at 75~80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com