Metal powder manufacturing device capable of controlling grain size of metal powder

A technology of metal powder and powder milling device, which is applied in the field of metal powder manufacturing equipment, can solve the problems of difficult particle size control and low powder yield, and achieves the effects of high powder milling efficiency, high yield and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

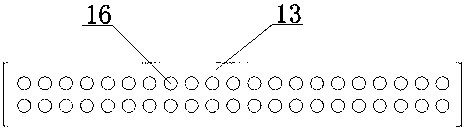

[0022] As a preferred embodiment of the present invention, the leaky screen 13 is provided with a small leaky screen hole 16 .

[0023] As a preferred embodiment of the present invention, the number of the two fixing rods 15 is two.

[0024] As a preferred embodiment of the present invention, the position of the heating crucible 3 corresponds to that of the rotating cup 2 .

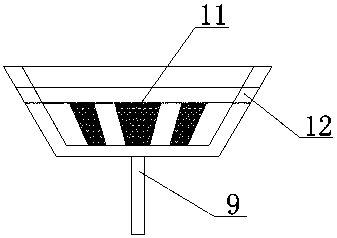

[0025] As a preferred embodiment of the present invention, the start switch is connected to a storage battery or an external power supply through wires, and the storage battery or external power supply is connected to the motor 8 , the annular gas atomizer 12 and the heating coil 6 through wires.

[0026] Working principle: When using this metal powder making device for controlling the particle size of metal powder, put the metal liquid into the heating crucible 3, turn on the start switch, the battery or external power supply is the motor 8, the annular gas atomizer 12 and the heating coil 6 Electric en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com