Multi-spindle electromechanical fully automatic adjustable wheelbase milling and drilling compound processing machine tool

A compound processing, electromechanical technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of processing efficiency and low degree of automation, and achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

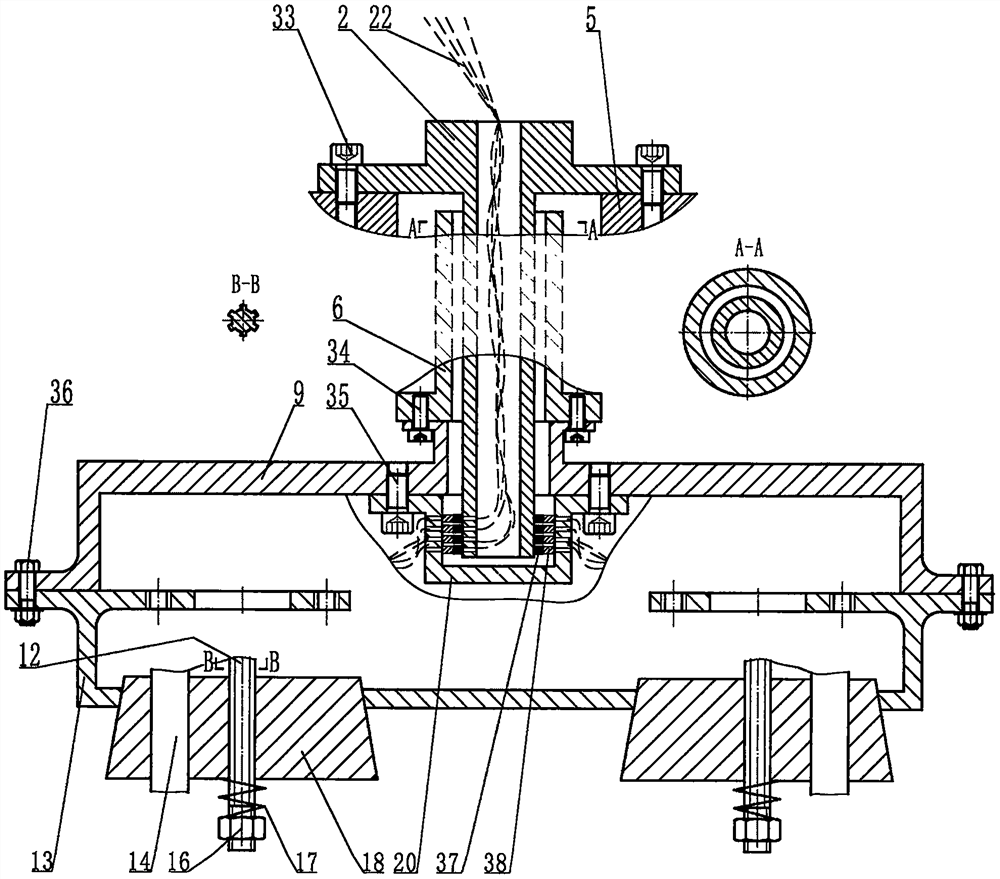

[0029] Multi-spindle electromechanical fully automatic adjustable wheelbase milling-drilling compound machining machine figure 1 , figure 2 , image 3 , including: main motor 1, fixed ring frame 2, main shaft upper bearing 3, main shaft gear 4, main shaft box 5, main shaft 6, electromagnetic brake 7, main shaft lower bearing 8, cutter head upper shell 9, distance control motor 10, electromagnet Upper 11, spline threaded shaft 12, cutter head lower shell 13, electric spindle 14, cutter 15, nut 16, spring 17, pitch-adjusting cone 18, lower electromagnet 19, moving ring frame 20, control drive system 21, data Drive line 22, base 23, bed 24, machine tool lifting platform 25, longitudinal feed table 26, transverse feed table 27, lead screw bearing 28, lead screw nut 29, lead screw 30, lift motor 31, motor shaft Ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com