A kind of polycrystalline manganese dioxide/carbon nanotube composite material and its preparation method and application

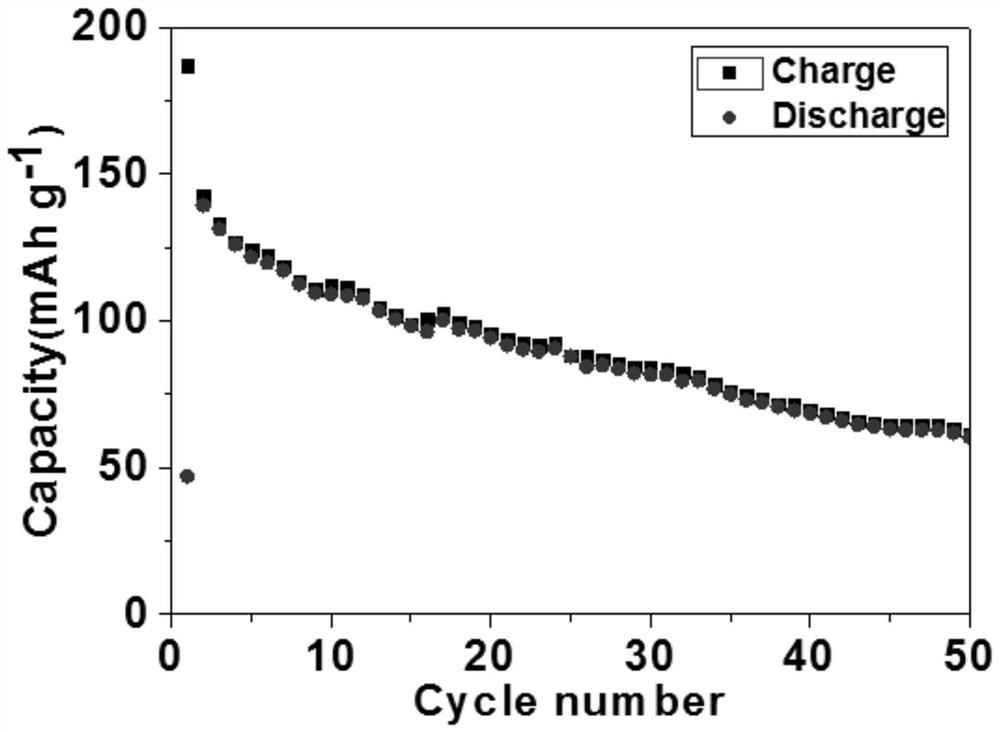

A technology of multi-walled carbon nanotubes and carbon nanotubes, which is applied in the field of polycrystalline MnO2/carbon nanotube composite materials and their preparation, can solve the problems of structural expansion, poor electrical conductivity, and inhibit the practical application value of sodium-ion batteries, and can achieve production The effect of short cycle, low energy consumption and novel design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

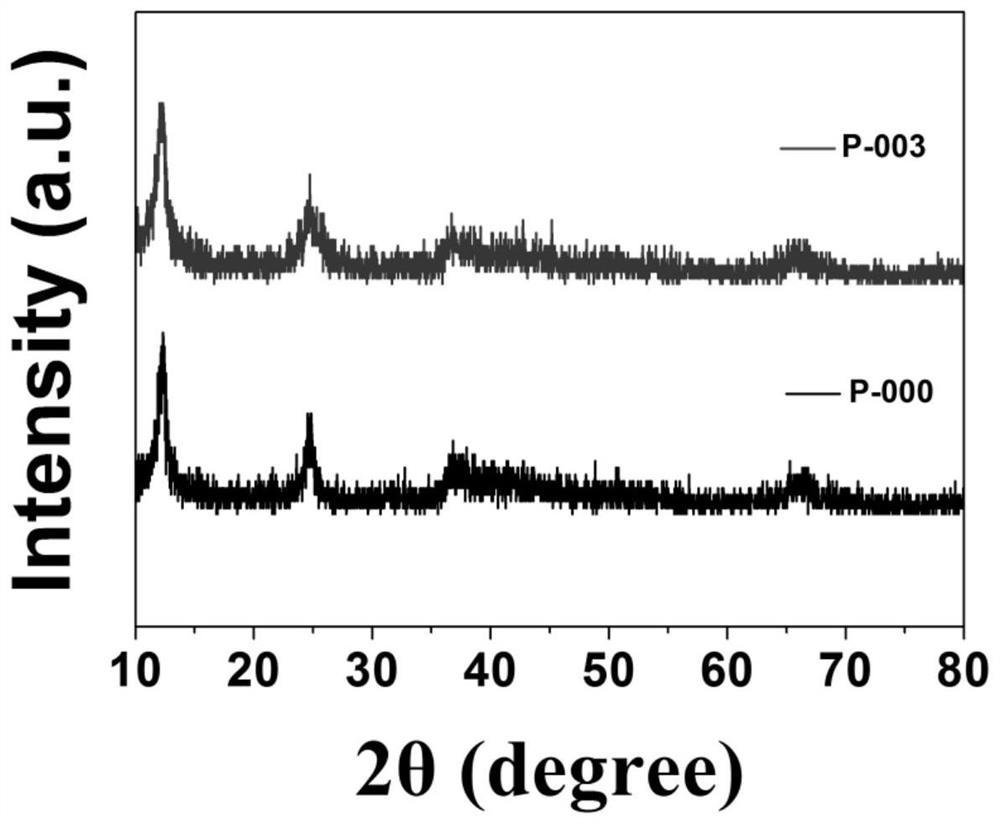

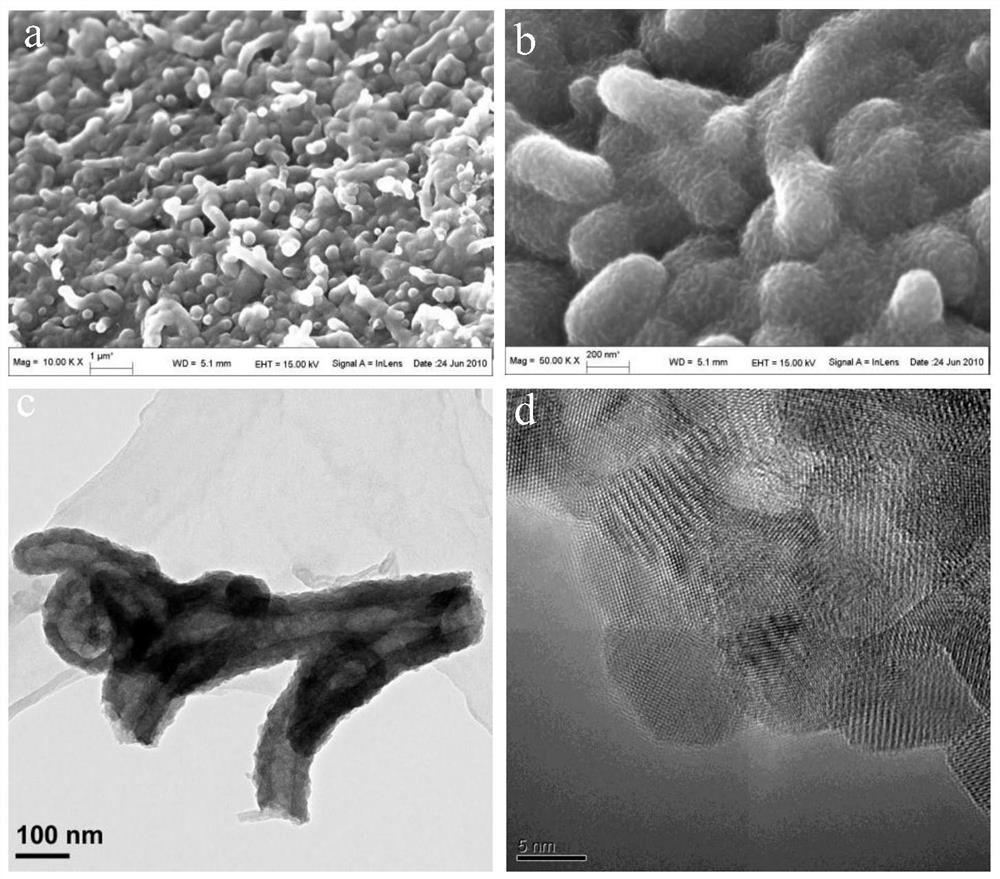

[0026] A polycrystalline MnO 2 / The preparation method of carbon nanotube composite material, comprises the following steps:

[0027] 1) Take 0.2g carboxylated multi-walled carbon nanotubes (AF-MWCNTs), 2.1g potassium permanganate (KMnO 4 ), placed in a mortar, fully ground evenly to obtain a mixture;

[0028] 2) In an air atmosphere, the mixture was raised from room temperature to 290 °C at a heating rate of 10 °C / min, kept for 2 hours, and cooled to room temperature;

[0029] 3) Rinse the product treated in step 2) with distilled water for 3 to 5 times, then with ethanol for 3 to 5 times, and dry at 85°C for 14 hours in a vacuum environment to obtain polycrystalline MnO 2 / carbon nanotube composites.

Embodiment 2

[0031] A polycrystalline MnO 2 / The preparation method of carbon nanotube composite material, comprises the following steps:

[0032] 1) Take 0.3g carboxylated multi-walled carbon nanotubes (AF-MWCNTs), 2.6g potassium permanganate (KMnO 4 ), placed in a mortar, fully ground evenly to obtain a mixture;

[0033] 2) In an air atmosphere, the mixture was raised from room temperature to 300 °C at a heating rate of 5 °C / min, kept for 2 hours, and cooled to room temperature;

[0034] 3) Rinse the product treated in step 2) with distilled water for 3 to 5 times, then with ethanol for 3 to 5 times, and dry at 70°C for 12 hours in a vacuum environment to obtain polycrystalline MnO 2 / carbon nanotube composites.

Embodiment 3

[0036] A polycrystalline MnO 2 / The preparation method of carbon nanotube composite material, comprises the following steps:

[0037] 1) Take 0.5g carboxylated multi-walled carbon nanotubes (AF-MWCNTs), 3.2g potassium permanganate (KMnO 4 ), placed in a mortar, fully ground evenly to obtain a mixture;

[0038] 2) In an air atmosphere, the mixture was raised from room temperature to 310 °C at a heating rate of 15 °C / min, kept for 2 hours, and cooled to room temperature;

[0039] 3) Rinse the product treated in step 2) with distilled water for 3 to 5 times, then with ethanol for 3 to 5 times, and dry at 50°C for 16 hours in a vacuum environment to obtain polycrystalline MnO 2 / carbon nanotube composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com