Dust-proof temperature control type computer mainframe box

A main box and computer technology, applied in the computer field, can solve problems such as limited temperature control effect and inability to achieve dustproof effect, and achieve the effects of improving anti-aging performance, good mechanical performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

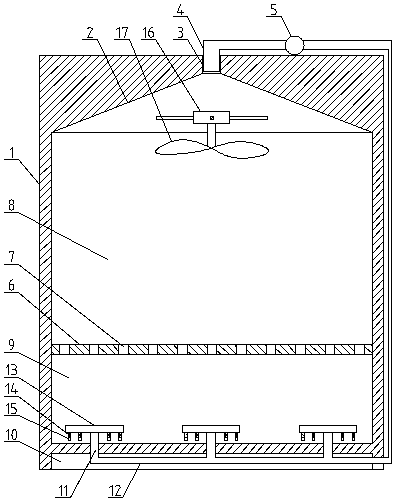

[0042] Such as figure 1 As shown, a dust-proof and temperature-controlled main computer box 1 includes a main box 1, the main box 1 is a closed structure, and the inner top of the main box 1 is an inverted funnel-shaped structure 2, and the inverted funnel-shaped The upper opening 3 of the structure 2 communicates with the air inlet of the micro air pump 5 arranged outside the main chassis 1 through the first pipe 4 .

[0043] A transverse partition 6 is arranged near the bottom in the main chassis 1, and an air inlet 7 is provided on the transverse partition 6. The transverse partition 6 divides the interior of the main chassis 1 into an upper part for accommodating the computer mainframe hardware. The equipment chamber 8 and the lower part are used to contain the water chamber 9 for cooling water. The bottom of the main chassis 1 is provided with a groove 10 for accommodating pipes. The top of the groove 10 is provided with several upper parts extending into the water The s...

Embodiment 2

[0055] The difference from Example 1 is that the corrosion-resistant layer includes components and their contents: 52 parts of glycerol, 15 parts of nano-zinc oxide, tetraisopropylbis(dioctylphosphite acyloxy)titanic acid 0.6 parts of ester coupling agent, 0.05 parts of polydienyl propylene dimethyl ammonium chloride, 3 parts of polymethyl acrylate, 6 parts of chloroform, 8 parts of titanium dioxide, 3 parts of polyvinyl alcohol, 7 parts of manganese trioxide , 0.06 parts of tributyl phosphate, 6 parts of ammonium polyacrylate, 8 parts of polyvinylidene fluoride, 3 parts of N,N-dimethylformamide, 16 parts of deionized water.

[0056] The preparation method of the corrosion-resistant metal corrosion-resistant layer material comprises the following steps:

[0057] 1) Weigh the above weight parts of glycerin and tetraisopropylbis(dioctylphosphite acyloxy) titanate coupling agent, mix them, put them into an ultrasonic oscillator, frequency 25kHz, power 300W, oscillation time 35mi...

Embodiment 3

[0063] The difference from Example 1 is that the corrosion-resistant layer includes components and their contents: 55 parts of glycerol, 16 parts of nano-zinc oxide, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate 0.6 parts of coupling agent, 0.06 parts of polydienyl propylene dimethyl ammonium chloride, 3 parts of polymethyl methacrylate, 6 parts of chloroform, 9 parts of titanium dioxide, 3 parts of polyvinyl alcohol, 7 parts of manganese trioxide 0.07 parts of tributyl phosphate, 6 parts of ammonium polyacrylate, 9 parts of polyvinylidene fluoride, 3 parts of N,N-dimethylformamide, and 18 parts of deionized water.

[0064] The preparation method of the corrosion-resistant metal corrosion-resistant layer material comprises the following steps:

[0065]1) Weigh the glycerol and isopropyl tris(dioctyl pyrophosphate acyloxy) titanate coupling agent in the above weight parts and mix them, and put them into an ultrasonic oscillator with a frequency of 25kHz, a power of 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com