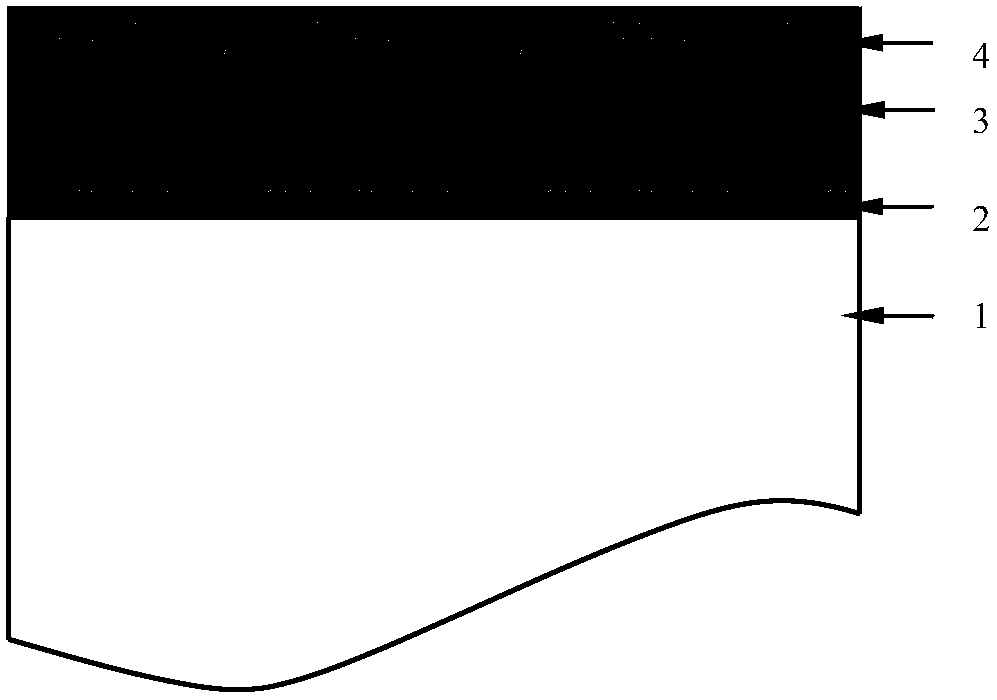

Soft-hard composite nanometer multi-coating cutter and preparation method thereof

A soft-hard composite and nano-multi-layer technology, which is applied in the coating, metal material coating process, superimposed layer plating, etc., can solve problems such as increased friction coefficient, coating peeling, and affecting the surface quality of the processed workpiece. Achieve the effect of improving the hardness of the coating, enhancing the bonding force and reducing the residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of the preparation method of embodiment one are as follows:

[0032] (1) Pre-treatment: mirror-polish the cemented carbide substrate, put it in acetone solution for ultrasonic cleaning for 15 minutes, then put it in alcohol solution for ultrasonic cleaning for 15 minutes, dry it with nitrogen and put it into the vacuum chamber of the coating machine. During this process, it is forbidden to touch Touch the surface of the substrate, and the vacuum chamber is evacuated to 3.0×10 -4 Pa, heated to 350°C and held for 30 minutes.

[0033](2) Glow cleaning: Ar gas is introduced, the working pressure is 1.5Pa, and glow discharge cleaning is carried out for 20 minutes to remove tiny impurities attached to the surface of the substrate.

[0034] (3) Depositing Zr: DC magnetron sputtering technology was adopted, a pure Zr target was placed on the DC target source, high-purity Ar gas was introduced, the Ar flow rate was 70 sccm, the deposition pressure was 0.5 Pa, the depo...

Embodiment 2

[0038] The steps of the preparation method of embodiment two are as follows:

[0039] (1) Pre-treatment: mirror-polish the cemented carbide substrate, put it in acetone solution for ultrasonic cleaning for 15 minutes, then put it in alcohol solution for ultrasonic cleaning for 15 minutes, dry it with nitrogen and put it into the vacuum chamber of the coating machine. During this process, it is forbidden to touch Touch the surface of the substrate, and the vacuum chamber is evacuated to 3.0×10 -4 Pa, heated to 350°C and held for 30 minutes.

[0040] (2) Glow cleaning: Ar gas is introduced, the working pressure is 1.5Pa, and glow discharge cleaning is carried out for 20 minutes to remove tiny impurities attached to the surface of the substrate.

[0041] (3) Depositing Zr: DC magnetron sputtering technology was adopted, a pure Zr target was placed on the DC target source, high-purity Ar gas was introduced, the Ar flow rate was 70 sccm, the deposition pressure was 0.5 Pa, the dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com