Light-weight waste porcelain slag aggregate regeneration porcelain imitation product and preparation method thereof

A lightweight and porcelain slag technology, which is applied in the field of lightweight waste porcelain slag aggregate regenerated imitation porcelain products and its preparation, can solve the problems of many surface and internal voids, inconvenient transportation and handling, and affecting the appearance of cement products, etc. , achieve unique aesthetic value, avoid structural cracks, and enhance drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

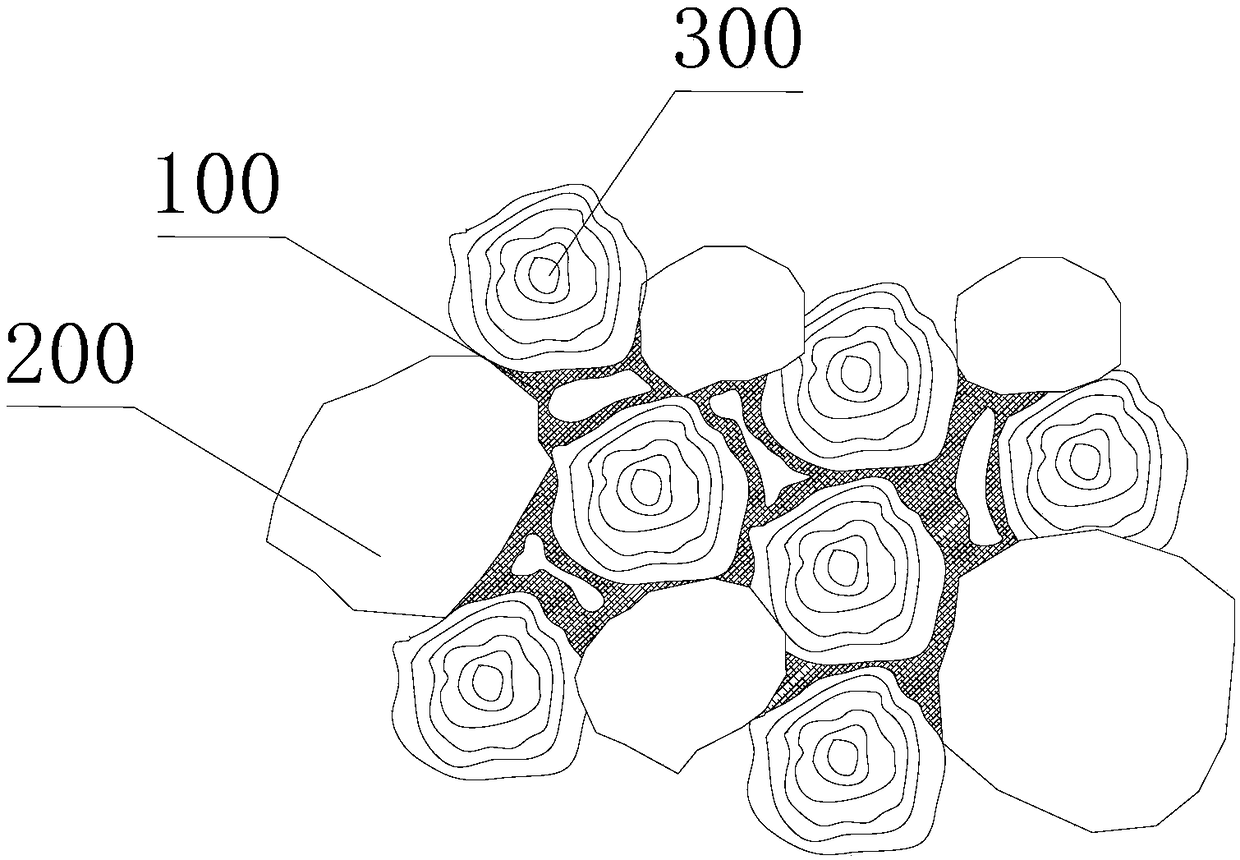

[0026] Specific embodiment 1: Lightweight waste porcelain slag aggregate regenerated imitation porcelain products include the following components in parts by weight: 40 parts of sulphoaluminate cement, 40 parts of waste porcelain slag, 4 parts of alkali-resistant glass fiber filaments, alkali-resistant 4 parts of glass fiber mat, 3.5 parts of polymer emulsion, 0.5 parts of water reducer, 5 parts of waste gypsum mold residue, 10 parts of water, 5 parts of toner.

specific Embodiment 2

[0027] Specific Example 2: Lightweight waste porcelain slag aggregate regenerated imitation porcelain products include the following components in parts by weight: 40 parts of sulphoaluminate cement, 40 parts of waste porcelain slag, 4 parts of alkali-resistant glass fiber filaments, alkali-resistant 4 parts of glass fiber mat, 3.5 parts of polymer emulsion, 0.5 part of water reducer, 5 parts of waste gypsum mold slag, 10 parts of water, 5 parts of toner, calculated according to the weight ratio, the polymer emulsion includes 40-50% butyl Benzene copolymer.

specific Embodiment 1 2

[0028] Specific embodiments one and two, the preparation method of regenerating imitation porcelain products from lightweight waste porcelain slag aggregates, comprises the following steps:

[0029] Step 1, crushing, crushing waste porcelain and waste plaster molds respectively, passing the crushed waste porcelain through a 7mm sieve, and passing the crushed waste gypsum mold through a 2mm sieve, and screened out the waste porcelain slag and waste porcelain slag that meet the particle size requirements Waste gypsum mold slag, the material on the screen is returned to the crusher for re-crushing;

[0030] Step 2, ingredients, in parts by weight, according to the following formula to configure the raw materials of lightweight waste porcelain slag aggregates to regenerate imitation porcelain products: 40 parts of sulphoaluminate cement, 40 parts of waste porcelain slag, 4 parts of alkali-resistant glass fiber filaments, 4 parts of alkali-resistant glass fiber felt, 3.5 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com