Quartz and methods of increasing its resistance to laser damage

A technology of anti-laser and quartz, which is applied in the field of optical materials, can solve the problems that subsurface microcracks and subsurface defects cannot be completely eliminated, thermal distortion of large-diameter components, and the existence of a pit surface, etc., to achieve stress resistance, uniform heating, and good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

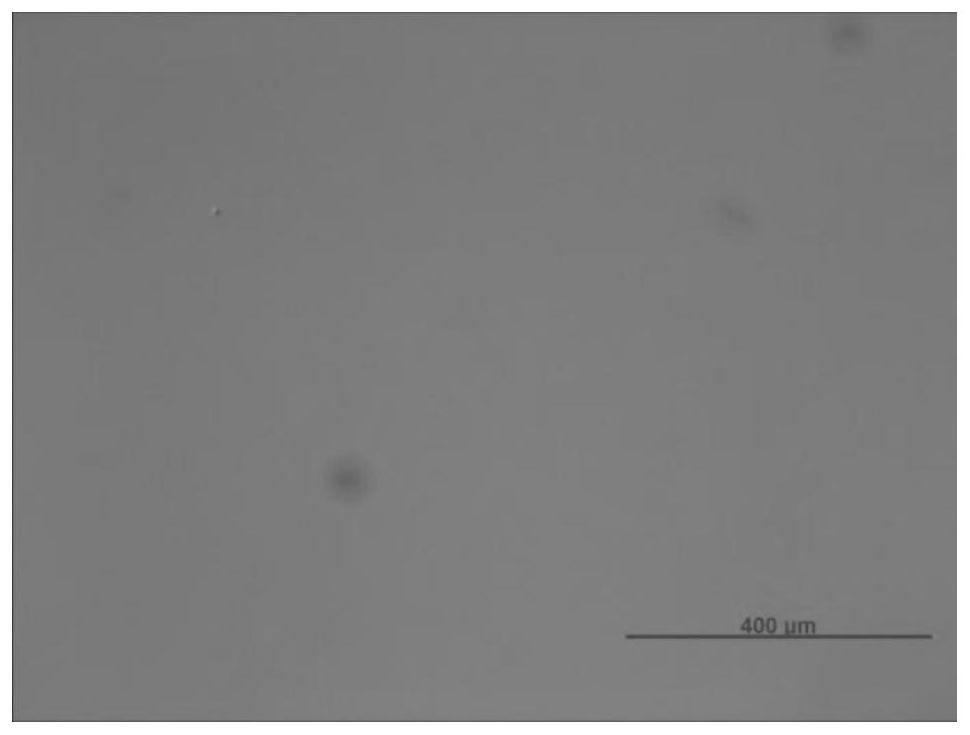

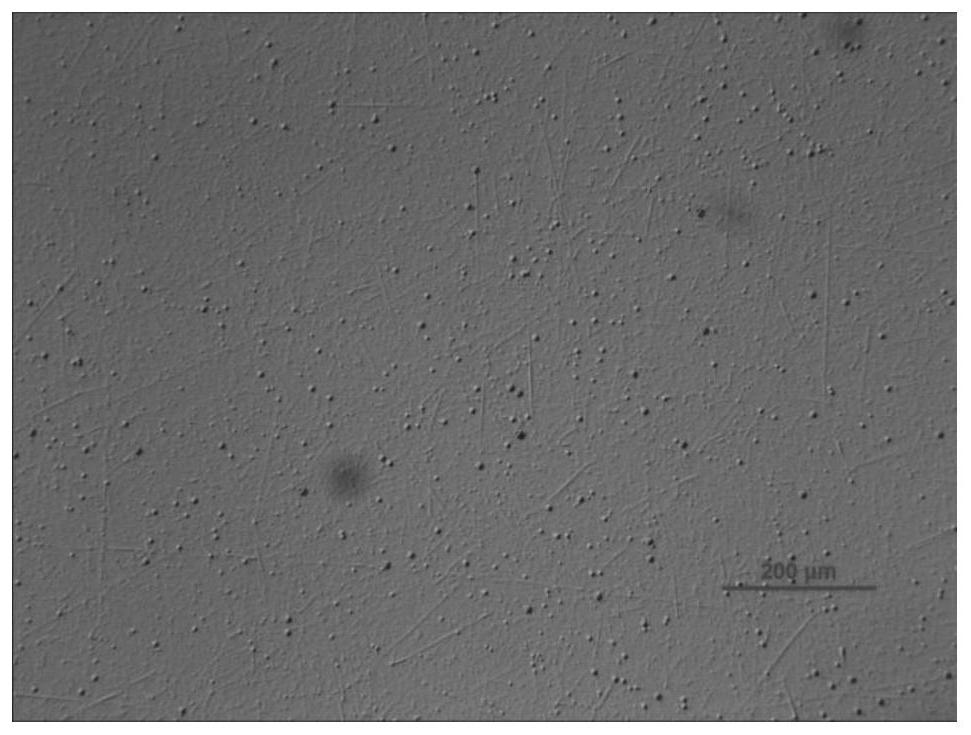

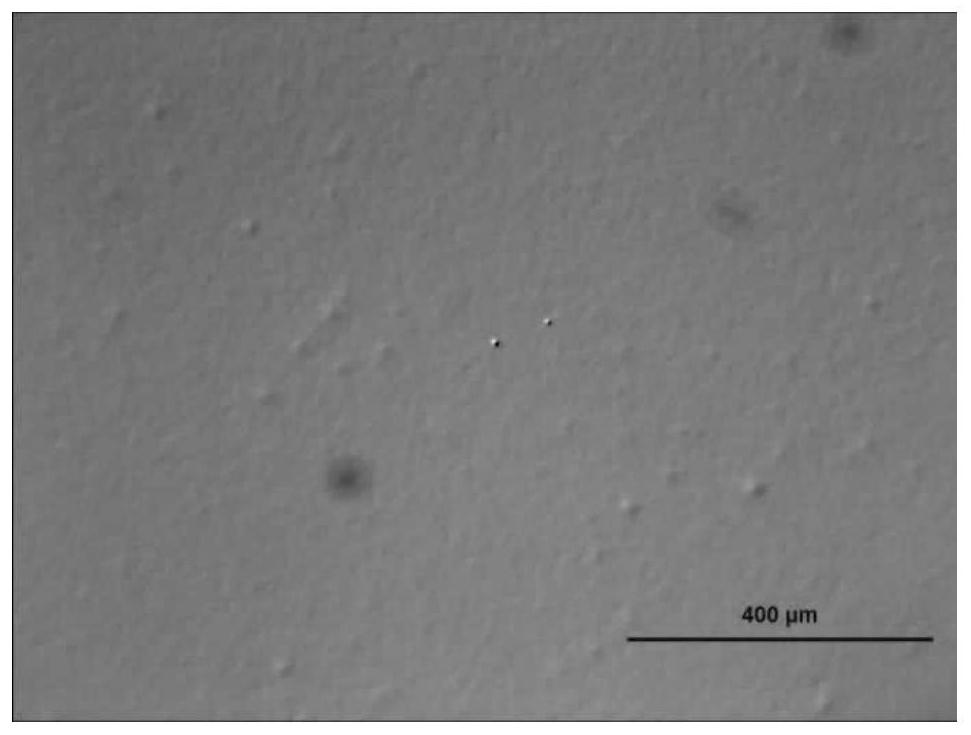

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for increasing the anti-laser damage performance of quartz, comprising the following steps:

[0044] S1, pretreatment;

[0045] Fix a 50mm×50mm×5mm fused silica substrate on a polytetrafluoroethylene fixture, first use 10% Micro90 alkaline washing solution to ultrasonically clean it for 1 hour, then rinse it with ultrapure water for 1 hour, and then use acid solution washing solution to ultrasonically clean it for 1 hour. Wash for 2 hours and rinse with ultrapure water for 1 hour. Wherein, the acid liquid is a liquid obtained by mixing nitric acid and hydrogen peroxide at a volume ratio of 1.5:1.

[0046] S2, etching;

[0047] Etching with hydrofluoric acid buffer solution for 2 hours and rinsing with ultrapure water for 1 hour to obtain a fused silica substrate with an etching depth of 20 microns. Wherein, the hydrofluoric acid buffer solution is prepared by mixing hydrofluoric acid, fluoride salt and water in a volume ratio of 1:4:...

Embodiment 2

[0053] This embodiment provides a method for increasing the anti-laser damage performance of quartz, comprising the following steps:

[0054] S1, pretreatment;

[0055] Fix a 50mm×50mm×5mm fused silica substrate on a polytetrafluoroethylene fixture, first use 10% Micro90 alkaline washing solution to ultrasonically clean it for 1 hour, then rinse it with ultrapure water for 1 hour, and then use acid solution washing solution to ultrasonically clean it for 1 hour. Wash for 1 hour and rinse with ultrapure water for 1 hour. Wherein, the acid liquid is a liquid obtained by mixing nitric acid and hydrogen peroxide at a volume ratio of 2.5:1.

[0056] S2, etching;

[0057] Etching with hydrofluoric acid buffer solution for 3 hours and rinsing with ultrapure water for 1 hour to obtain a fused silica substrate with an etching depth of 30 microns. Wherein, the hydrofluoric acid buffer solution is prepared by mixing hydrofluoric acid, fluoride salt and water in a volume ratio of 1:4:1...

Embodiment 3

[0062] This embodiment provides a method for increasing the anti-laser damage performance of quartz, comprising the following steps:

[0063] S1, pretreatment;

[0064] Fix a 50mm×50mm×5mm fused silica substrate on a polytetrafluoroethylene fixture, first use 10% Micro90 alkaline washing solution to ultrasonically clean it for 1 hour, then rinse it with ultrapure water for 0.5 hour, and then use acid solution washing solution to ultrasonically clean it. Wash for 2 hours and rinse with ultrapure water for 1 hour. Wherein, the acid liquid is a liquid obtained by mixing nitric acid and hydrogen peroxide at a volume ratio of 2:1.

[0065] S2, etching;

[0066] Etching with hydrofluoric acid buffer solution for 0.5 hour and rinsing with ultrapure water for 1 hour to obtain a fused silica substrate with an etching depth of 5 microns. Wherein, the hydrofluoric acid buffer solution is prepared by mixing hydrofluoric acid, fluoride salt and water according to a volume ratio of 1:4:8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com