Tape-casting post-treatment system and technology for degradable matte film

A tape-casting and matt film technology, which is applied in the post-processing system and process field of degradable matt film tape-casting, and can solve the problems of not having stable cutting of the film side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

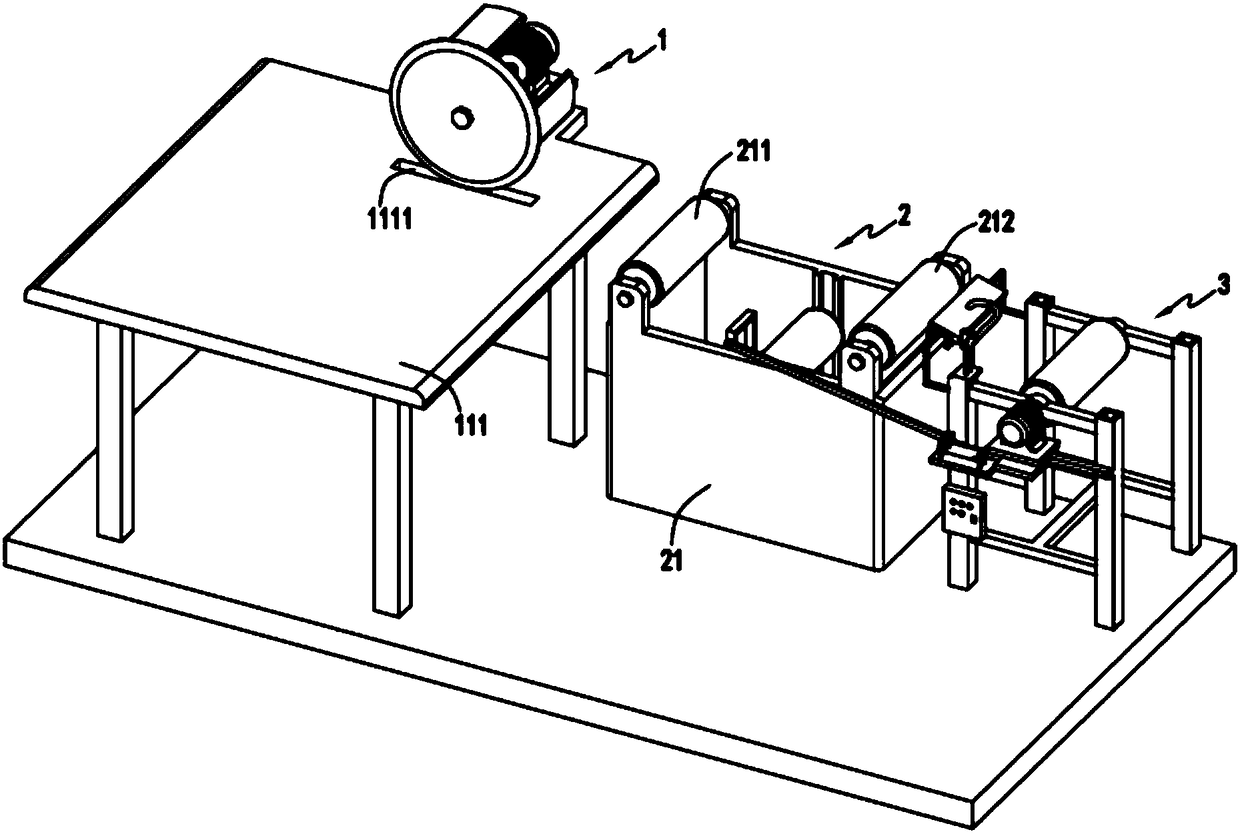

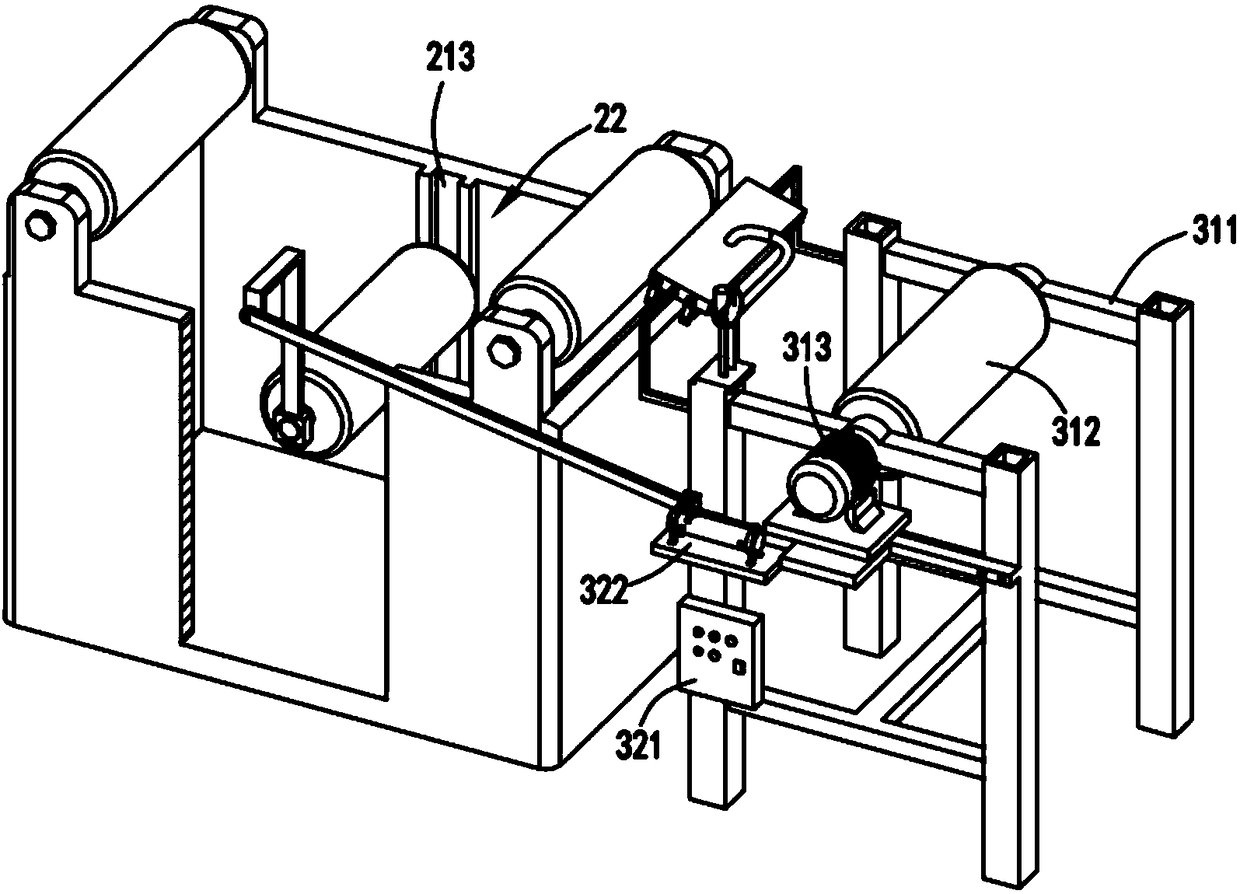

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7As shown, the post-processing system for degradable matte film casting includes a slitting device 1, and the slitting device 1 includes a cutter mechanism 11 for cutting off the side waste film 10 of the casting film and a In the cutting process, the support mechanism 12 that presses and supports the waste film 10; the buffer device 2, the buffer device 2 is arranged behind the cutting device 1, the buffer device 2 includes a water tank 21, and is arranged in the water tank 21 A buffer mechanism 22 for making the waste film 10 into a U-shaped transmission from the inside of the water tank 21; a winding device 3, which is arranged behind the buffer device 2, and the winding device 3 includes a winding A mechanism 31 and a control mechanism 32 , the winding mechanism 31 is used for winding the waste film 10 , and the control mechanism 32 adjusts the winding speed of the winding me...

Embodiment 2

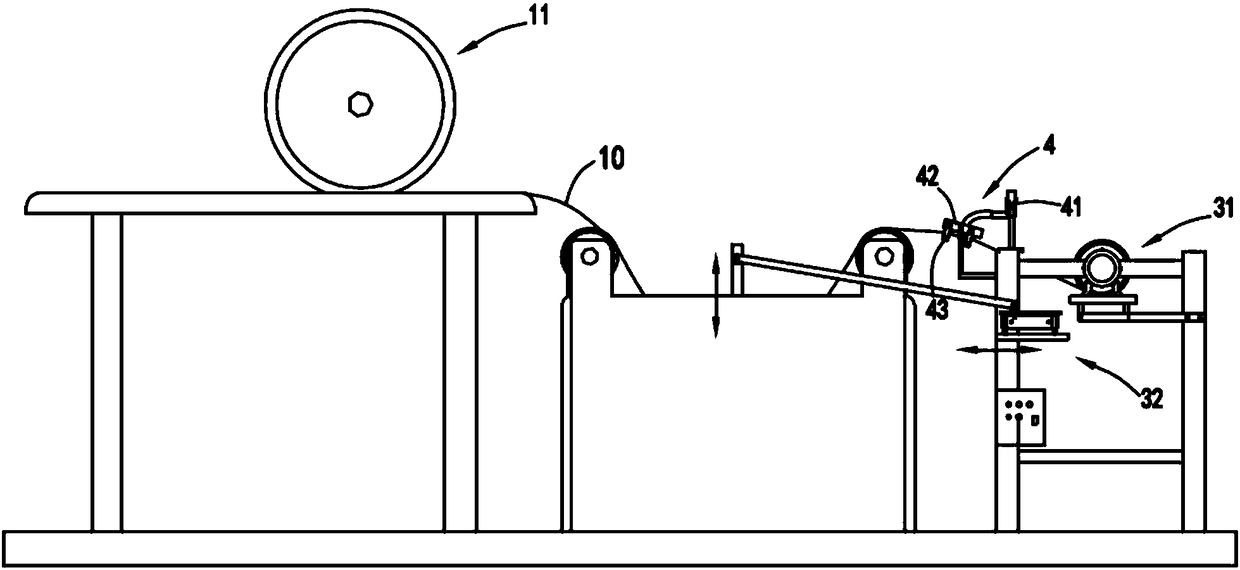

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, a blowing mechanism 4 for drying the waste film 10 coming out of the water tank 21 is provided between the water tank 21 and the winding device 3, The blowing mechanism 4 includes a blower 41 and a blower cover 42 communicating with the blower 41 , and a plurality of support rollers 43 are arranged below the air outlet of the blower cover 42 .

[0059] In this embodiment, the blowing mechanism 4 is set so that the waste film 10 can remove the moisture brought by the waste film 10 from the water tank 21 by the blowing mechan...

Embodiment 3

[0061] Such as Figure 8 As shown, the post-processing process of degradable matt film tape casting includes the following production steps:

[0062] a. Slitting process, the cast film is transported to the slitting station, and the slitting device 1 at the slitting station cuts off the waste film 10 on the side of the cast film and removes the waste film 10 during the cutting process. The membrane 10 is pressed down to support;

[0063] b. buffering process, the cut waste film 10 is transported to the buffer station, and the buffer device 2 makes the waste film 10 into a U shape and is transported through the water tank 21;

[0064] c. Rewinding process, the waste film 10 transmitted through the water tank 21 is transported to the rewinding station, and the rewinding mechanism 31 located at the rewinding station rewinds the waste film 10;

[0065] d. Adjustment process, during the process of winding up the waste film 10 by the winding mechanism 31 in step c, the control mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com