Photovoltaic panel with circulating back cooling

A technology of photovoltaic panels and heat-conducting panels is applied in the field of solar cells to achieve the effects of improving heat dissipation efficiency, low contact resistance, and low single-chip paste requirement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Photovoltaic panel 1 of embodiment 1 circulation back cooling

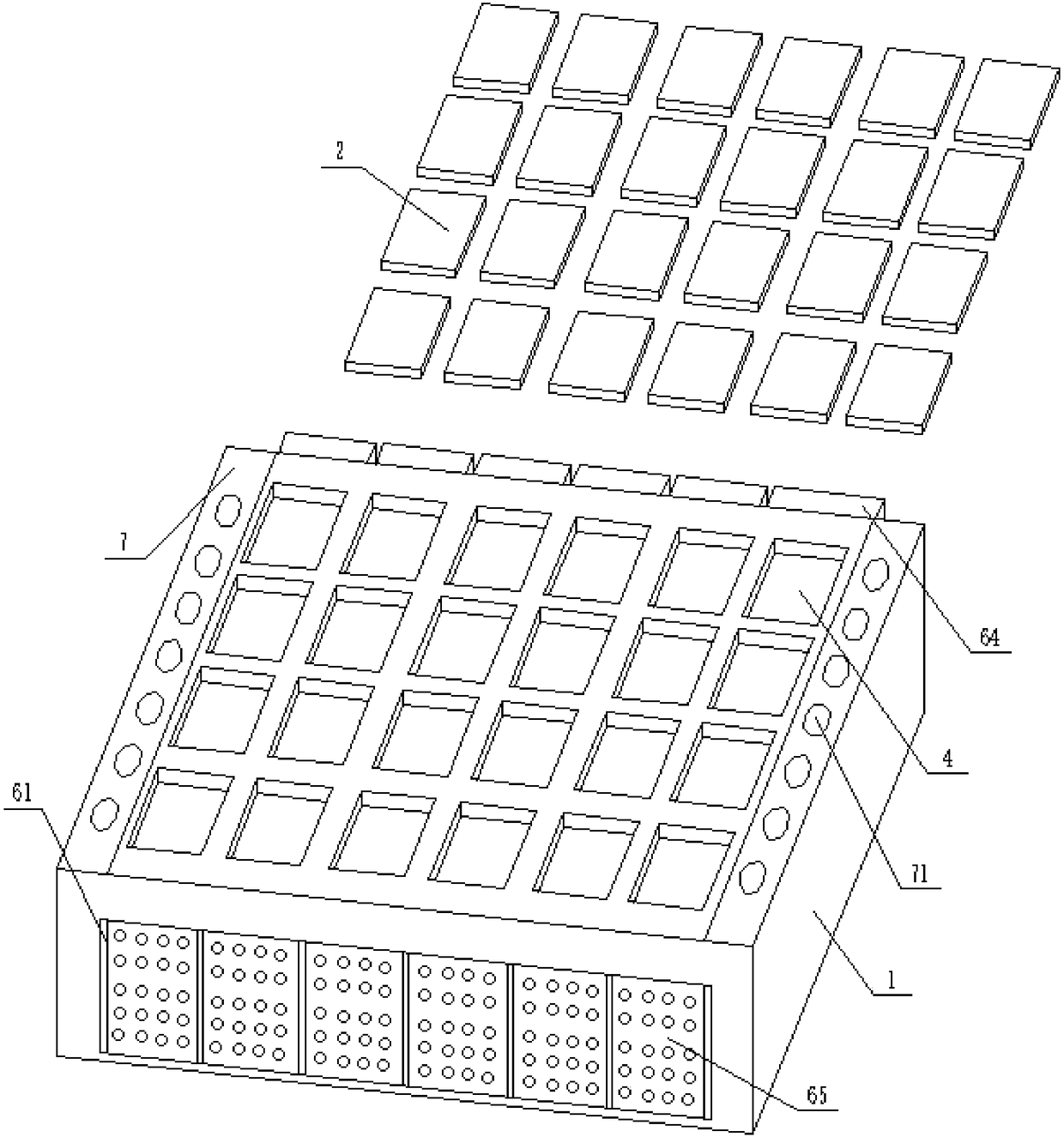

[0025] Figure 1-4 As shown, a photovoltaic panel with circulating back heat dissipation includes a rectangular mounting base 1 and a plurality of solar cells 2, and the solar cells 2 include a silicon chip and silver electrode grid lines arranged on the front side of the silicon chip. The electrode grid line is obtained by screen-printing conductive silver paste 1 on the silicon chip, and then obtained after drying and sintering. On the mounting base 1, a strip-shaped water collection tank 3 is provided vertically, and the strip-shaped water collection tank The notch of 3 is provided with a cover plate 7, and the cover plate 7 is provided with a water guide hole 71, and two strip-shaped water collection tanks 3 are respectively arranged near the sides of the mounting seat 1, and the upper surface of the mounting seat 1 A plurality of grooves 4 are provided, and a plurality of the grooves 4 are evenly dist...

Embodiment 2

[0036] Photovoltaic panel II of embodiment 2 circulation back cooling

[0037] Figure 1-4 As shown, a photovoltaic panel with circulating back heat dissipation includes a rectangular mounting base 1 and a plurality of solar cells 2, and the solar cells 2 include a silicon chip and silver electrode grid lines arranged on the front side of the silicon chip. The electrode grid line is screen-printed conductive silver paste II on the silicon chip, and the mounting seat 1 is provided with a strip-shaped water collection tank 3 facing vertically, and the notch of the strip-shaped water collection tank 3 is provided with a cover plate 7 , the cover plate 7 is provided with a water guide hole 71, and two strip-shaped water collection tanks 3 are respectively provided close to the side of the mounting base 1, and the upper surface of the mounting base 1 is provided with a plurality of grooves 4, more Each of the grooves 4 is evenly distributed between the two strip-shaped water colle...

Embodiment 3

[0048] Embodiment 3 Photovoltaic panel III with circulating back heat dissipation

[0049] Figure 1-4 As shown, a photovoltaic panel with circulating back heat dissipation includes a rectangular mounting base 1 and a plurality of solar cells 2, and the solar cells 2 include a silicon chip and silver electrode grid lines arranged on the front side of the silicon chip. The electrode grid lines are screen-printed conductive silver paste III on the silicon chip, and the mounting base 1 is provided with a strip-shaped water collection tank 3 facing vertically, and the notch of the strip-shaped water collection tank 3 is provided with a cover plate 7 , the cover plate 7 is provided with a water guide hole 71, and two strip-shaped water collection tanks 3 are respectively provided close to the side of the mounting base 1, and the upper surface of the mounting base 1 is provided with a plurality of grooves 4, more Each of the grooves 4 is evenly distributed between the two strip-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com