Double-component epoxy modified silane end-capped polypropylene oxide sealant and preparation method thereof

A polypropylene oxide and silane-capped technology, which is applied in the direction of epoxy resin adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of no patent reports, etc., and achieve improved tensile shear strength, good weather resistance, and adhesion The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

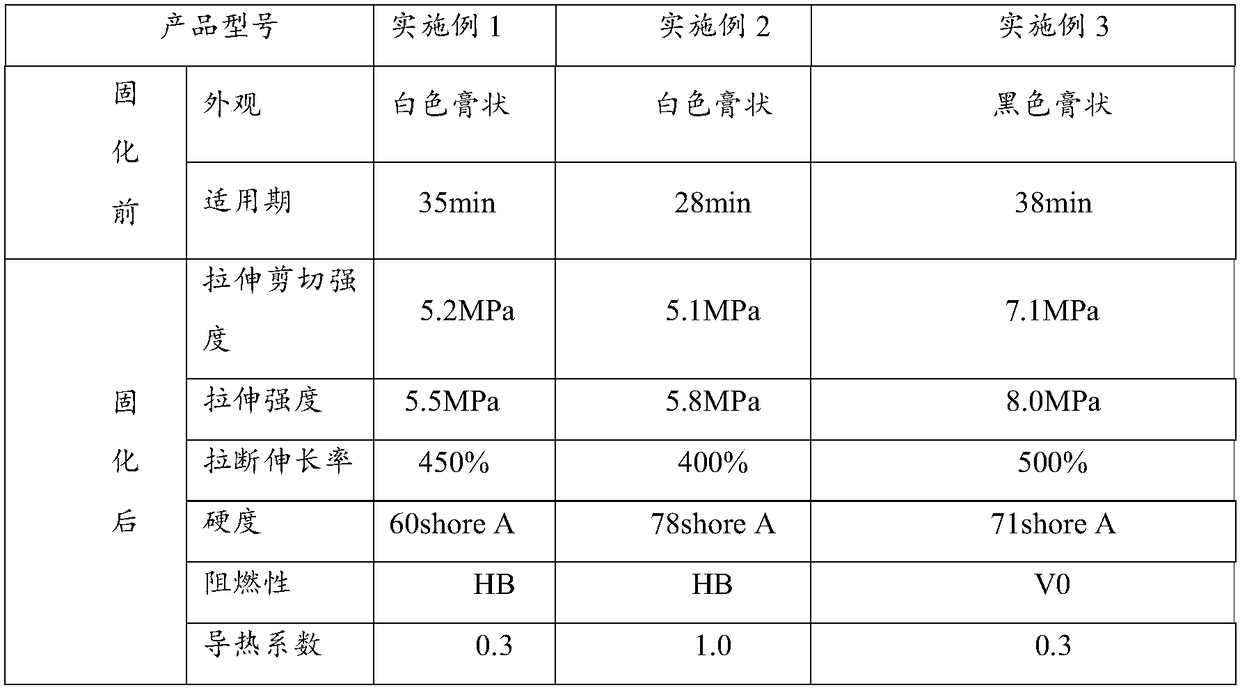

Examples

Embodiment 1

[0032] A kind of embodiment of the preparation method of two-component epoxy-modified silane-terminated polypropylene oxide sealant of the present invention, comprises the following steps:

[0033] (1) the bisphenol A type epoxy resin of 40 weight parts, the didecyl phthalate of 10 weight parts, the calcium carbonate of 60 weight parts, the fumed silica of 6 weight parts, the 2- (2-Hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 2 parts by weight of 2,6-di-tert-butyl-4-methylphenol, 5 parts by weight of bis(acetyl Pyruvate) dibutyltin is mixed evenly, and is sealed and packaged according to specifications to obtain component A;

[0034] (2) Mix 100 parts by weight of dimethoxysilyl-terminated polypropylene oxide, 5 parts by weight of polyoxypropylene glycol, and 60 parts by weight of silicon dioxide at 80°C and a vacuum of 0.095MPa , and maintained the above mixing conditions for 6 hours; after the temperature of the obtained mixture was dropped to below 50°C, add 6 p...

Embodiment 2

[0037] A kind of embodiment of the preparation method of two-component epoxy-modified silane-terminated polypropylene oxide sealant of the present invention comprises the following steps:

[0038] (1) 60 parts by weight of bisphenol A type epoxy resin, 15 parts by weight of 4,5-epoxy tetrahydrophthalate (2-ethyl) hexyl ester, 200 parts by weight of aluminum oxide, 8 parts by weight Parts of organic bentonite, 2 parts by weight of 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 1 part by weight of 2,6-di-tert-butyl-4- Dibutyltin dilaurate of methyl phenol and 4 parts by weight are mixed evenly, sealed and packaged according to specifications, and A component is obtained;

[0039](2) Mix 120 parts by weight of trimethoxysilane-terminated polypropylene oxide, 10 parts by weight of dibutyl phthalate, and 200 parts by weight of alumina at 100°C and 0.090MPa vacuum, and Maintain the above mixing conditions for 4 hours; after reducing the temperature of the obtained mix...

Embodiment 3

[0042] A kind of embodiment of the preparation method of two-component epoxy-modified silane-terminated polypropylene oxide sealant of the present invention comprises the following steps:

[0043] (1) the bisphenol F type epoxy resin of 80 weight parts, the didecyl phthalate of 20 weight parts, the calcium carbonate of 160 weight parts, the antimony oxide of 80 weight parts, the fumed silica of 2 weight parts , 1 weight part of 2-(2-hydroxy-3,5-dibutyl-tert-phenyl)-5-chlorobenzotriazole, 1.5 weight parts of 2,6-di-tert-butyl-4-methylphenol, 1 part by weight of bis(acetylacetonate) dibutyltin is mixed evenly, sealed and packaged according to specifications, and A component is obtained;

[0044] (2) 80 parts by weight of dimethoxysilyl-terminated polypropylene oxide, 20 parts by weight of chlorinated paraffin 52, and 70 parts by weight of carbon black are mixed uniformly at 120°C and 0.085MPa vacuum, and Maintain the above mixing conditions for 2 hours; after the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com